Camera horizontal plane inclination angle measuring method and device

A measurement method and level technology, applied in the direction of measuring devices, photographic devices, instruments, etc., can solve problems such as inability to obtain accurate results, splicing or transformation errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

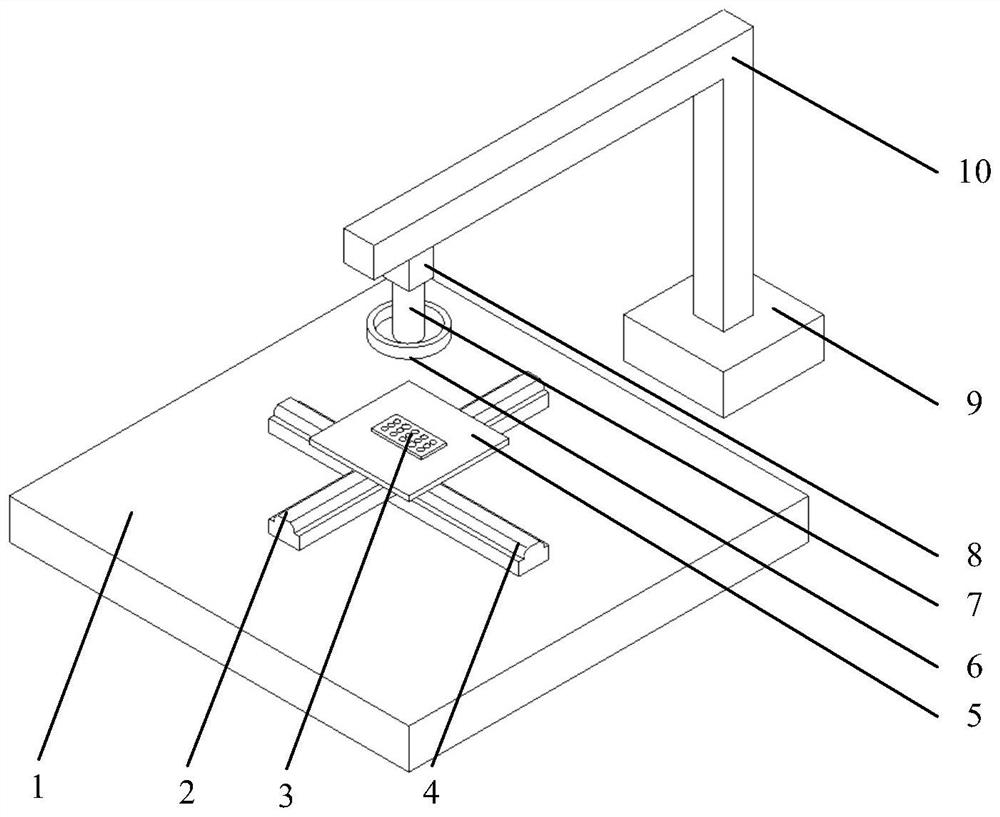

[0038] A method for measuring the inclination angle of the horizontal plane of a camera, comprising the following steps:

[0039] Step 1. Place the calibration board on the calibration board loading platform 5, set a part of the calibration board as a public area, control the movement of the working platform 1 by moving the motor, the calibration board enters the camera field of view, and take an image of the calibration board. This image includes the public domain of Baoding Edition;

[0040] Step 2. Keep the Y-axis 2 of the motor still, move the working platform 1 along the X-axis 4 of the motor by a step length Δd, and take another image of the calibration board, which includes the common area of the calibration board; among them, the images of the two calibration boards the images exist in the same common area;

[0041] Step 3. Process the two images of the calibration board, and the inclination angle of the camera horizontal plane is based on Calculated, where ΔV is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com