Distillation device for producing white spirit by distilling solid fermented grains

A technology of solid fermentation and distillation equipment, which is applied in the direction of distillation separation, preparation of alcoholic beverages, separation methods, etc., and can solve problems such as air compression, dead bed, penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

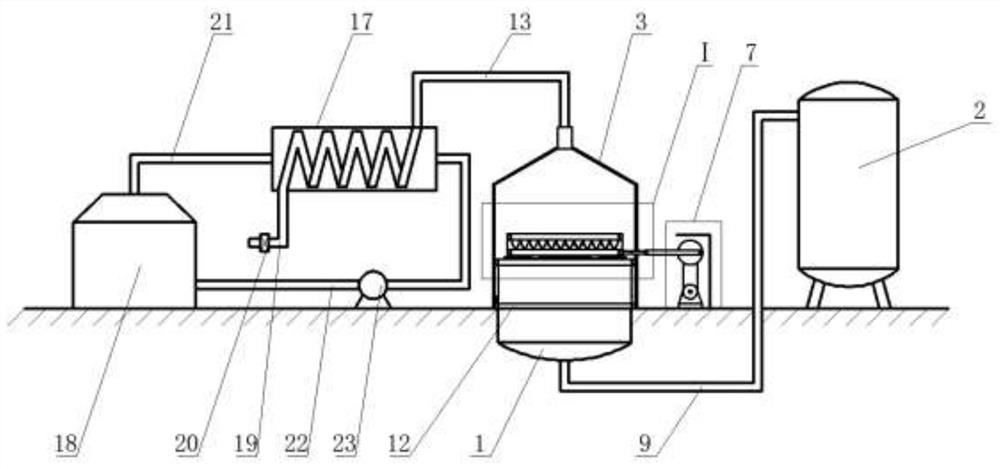

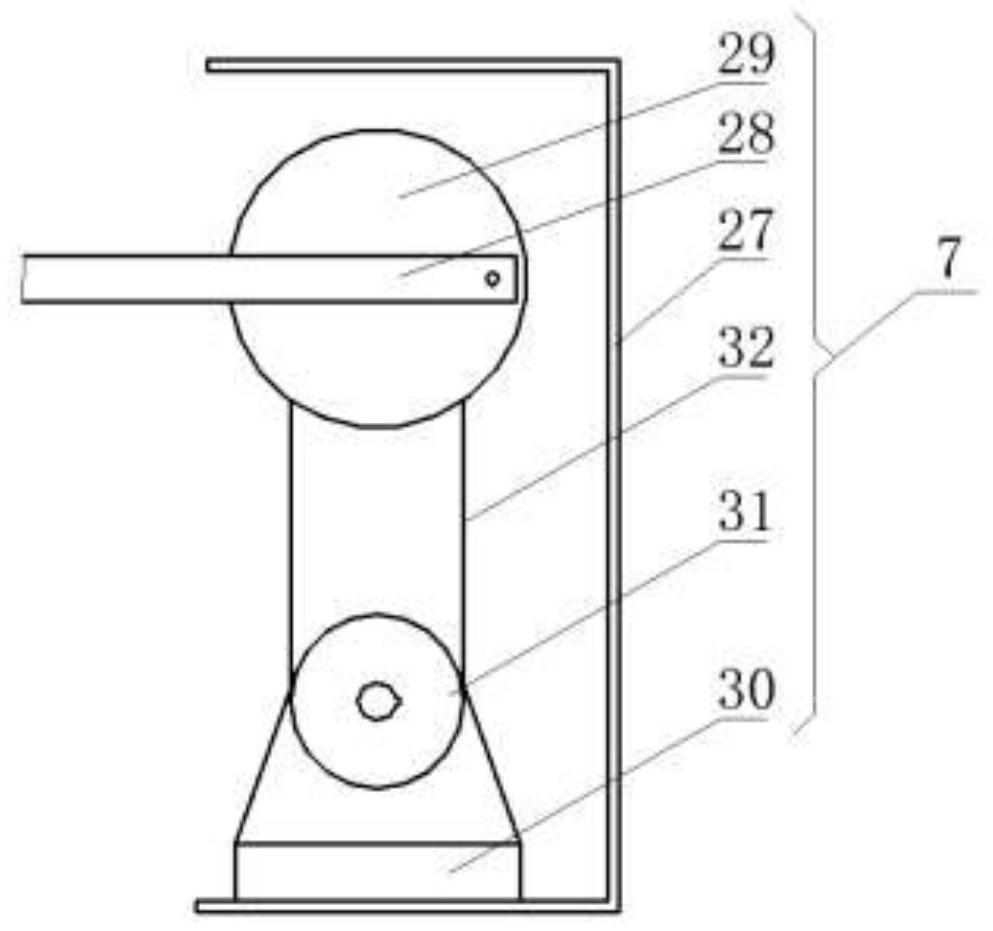

[0023] like Figure 1 to Figure 5 As shown, the present invention provides a distillation device for distilling solid fermented wine grains to produce liquor, including a heating ground pot 1, a steam boiler 2, a retort cover 3, a bottom frame 4, a transmission rod 5, a driving mechanism 7 and a plurality of retorts 8. The ground heating pot 1 is buried in the ground. The steam boiler 2 is connected to the ground heating pot 1 through the steam supply pipe 9. The steamer cover 3 is closed on the ground heating pot 1. The top of the steamer cover 3 is connected with a wine steam pipe 13. A feed hopper 10 is arranged on the outer side wall of the cover 3, a door 11 is installed at the opening end of the feed hopper 10, a support frame 12 is arranged inside the retort cover 3, and guide rails are installed side by side on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com