Intelligent MBR-ozone oxidation combined device

A technology of ozone oxidation and combined device, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of insufficient mixing of MBR-ozone mixing device and reduced efficiency of ozone oxidation, etc. Achieve sufficient contact area and time to ensure continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

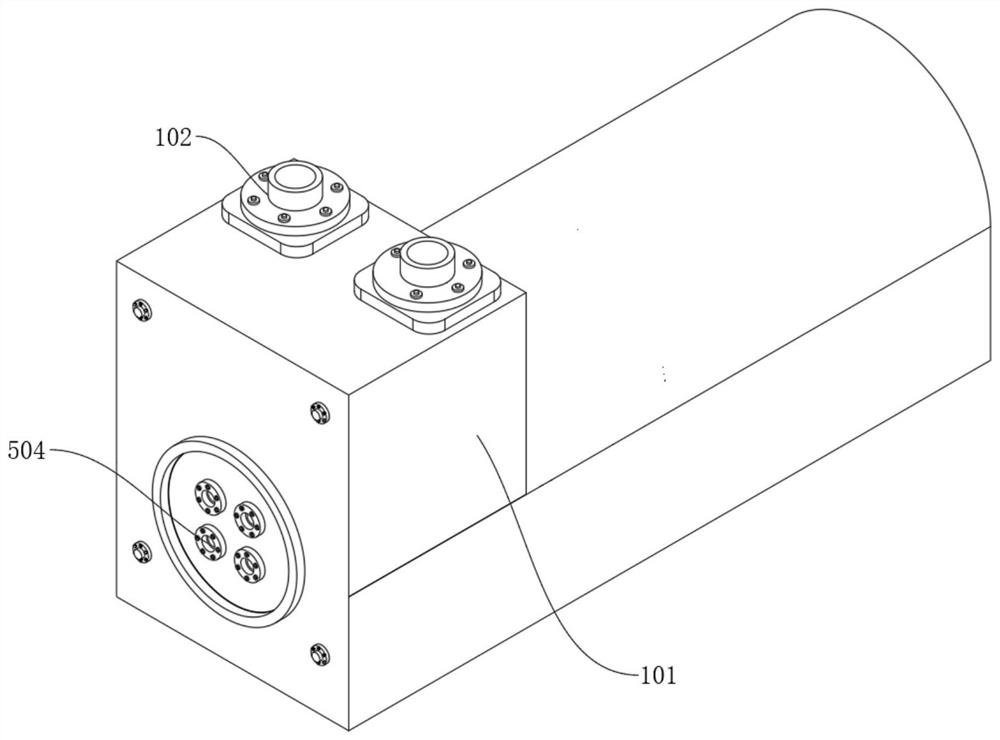

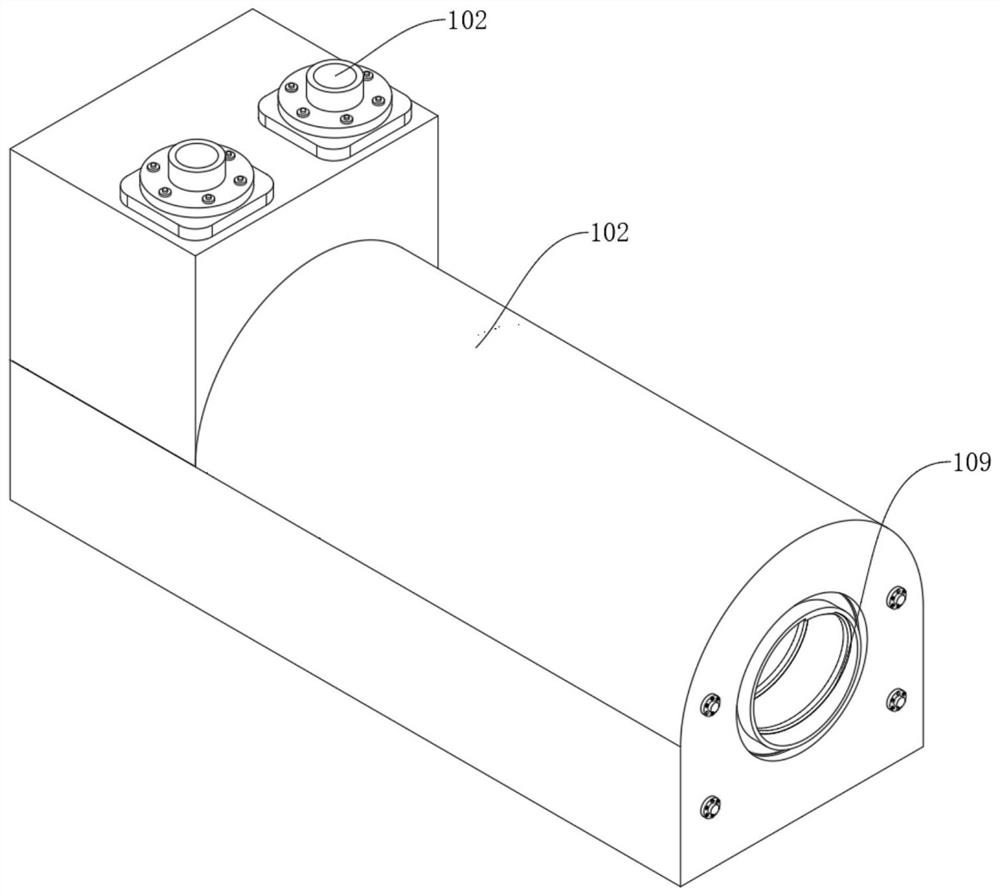

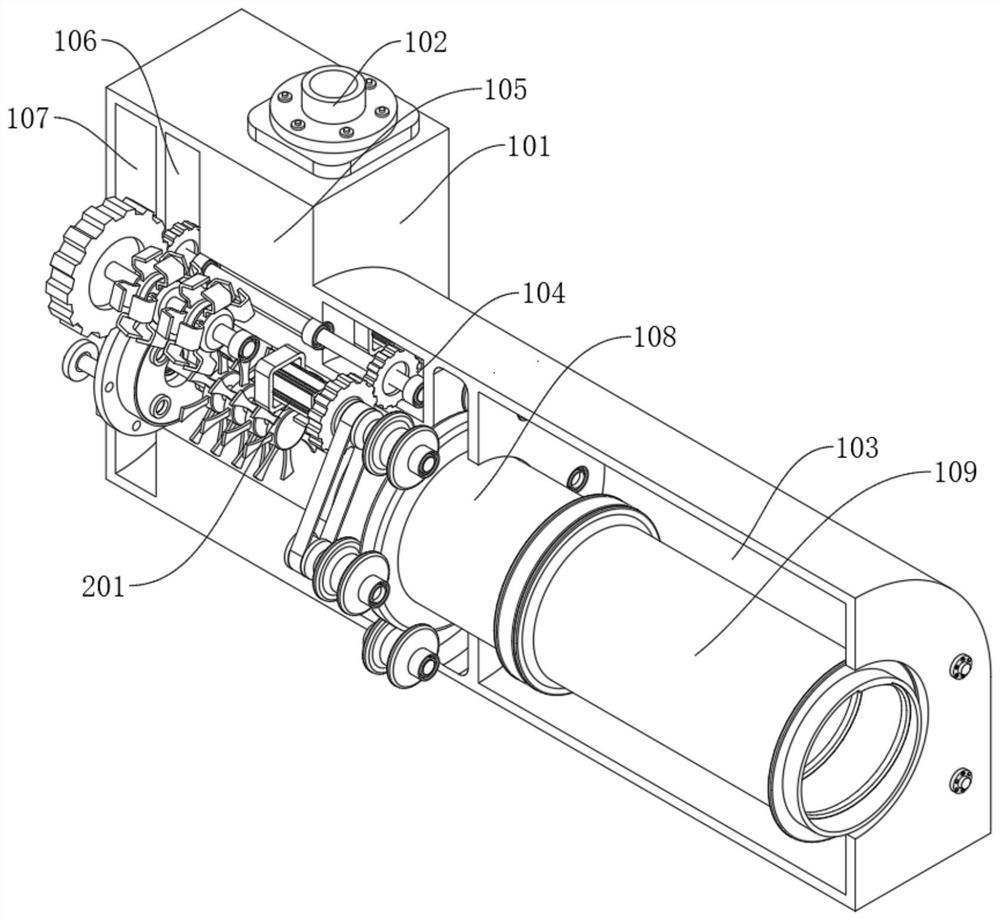

[0026] refer to Figure 1-4 , an intelligent MBR-ozone oxidation combined device, comprising: an ozone reaction mixing shell 101, the ozone reaction mixing shell 101 is sequentially provided with an ozone mixing bin 103, a sewage feeding bin 104, a driving bin 105, a linkage bin 106 and The aeration protection chamber 107, the driving mechanism is fixedly installed inside the driving chamber 105, the front end of the driving mechanism is fixedly connected to the upper side of the linkage mechanism, the linkage mechanism is fixedly installed inside the linkage chamber 106, the rear side of the driving mechanism is movably connected with the crushing mechanism, and the crushing mechanism moves Installed inside the sewage feed bin 104, the rear end of the driving mechanism is fixedly connected to the upper side of the ozone preliminary mixing mechanism, and the ozone preliminary mixing mechanism is movable installed inside the ozone mixing bin 103, and the middle part of the linka...

Embodiment 2

[0029] Embodiment 2: Based on Embodiment 1, but different again is;

[0030]The driving mechanism includes: a servo motor 201, a driving gear 202, a linkage gear 203, a linkage shaft 204 and a transmission gear 205. The front and rear sides of the drive chamber 105 are fixedly installed with a servo motor 201. The front end of the main shaft of the servo motor 201 is connected with the drive gear 202 and The upper side of the linkage mechanism is fixedly connected, the inner side of the driving gear 202 is meshed with the front and rear sides of the linkage gear 203, the axis center of the linkage gear 203 is fixedly connected with the right side of the linkage shaft 204, and the left side of the linkage shaft 204 extends to the inside of the linkage chamber 106. The transmission gear 205 axis is fixedly connected, the front and rear sides of the transmission gear 205 are engaged with the crushing mechanism, the left end of the linkage shaft 204 is fixedly connected with the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com