Elevator car door plate surface polishing device

A technology for surface polishing and elevator car, which is applied in the field of elevator car door panel surface polishing devices, can solve the problems of insufficient polishing of elevator car door panels and the inability of polishing efficiency to meet actual production needs, etc., so as to achieve improved safety and comfort, The effect of ensuring stability and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

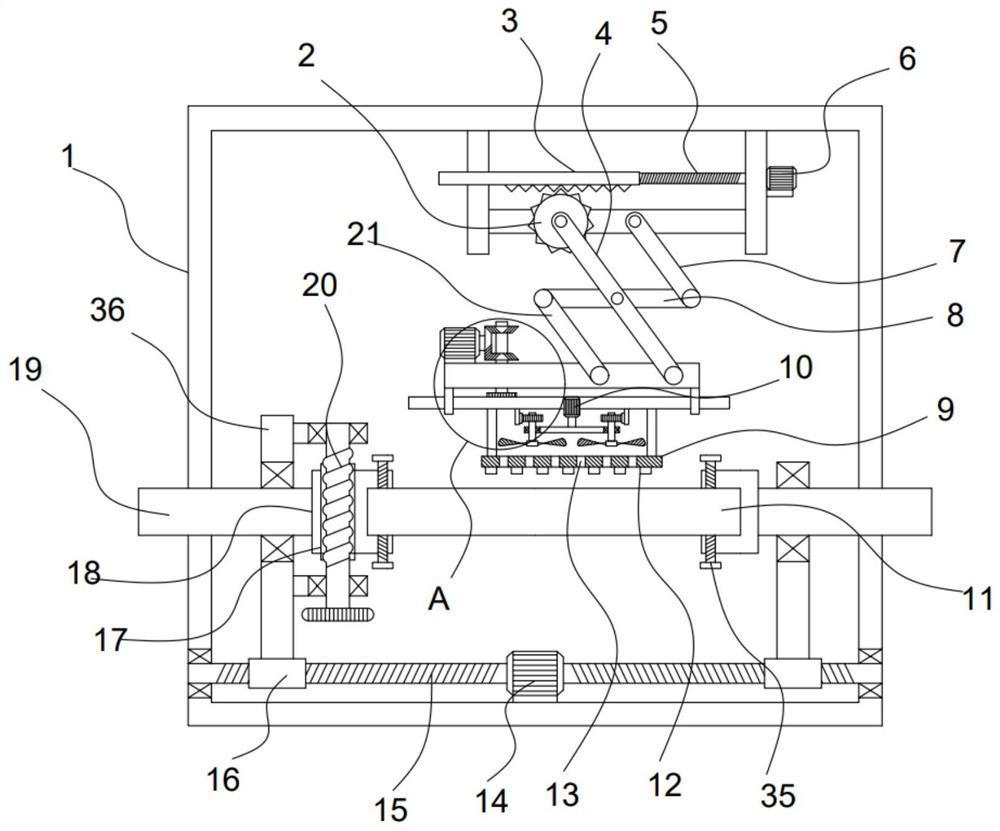

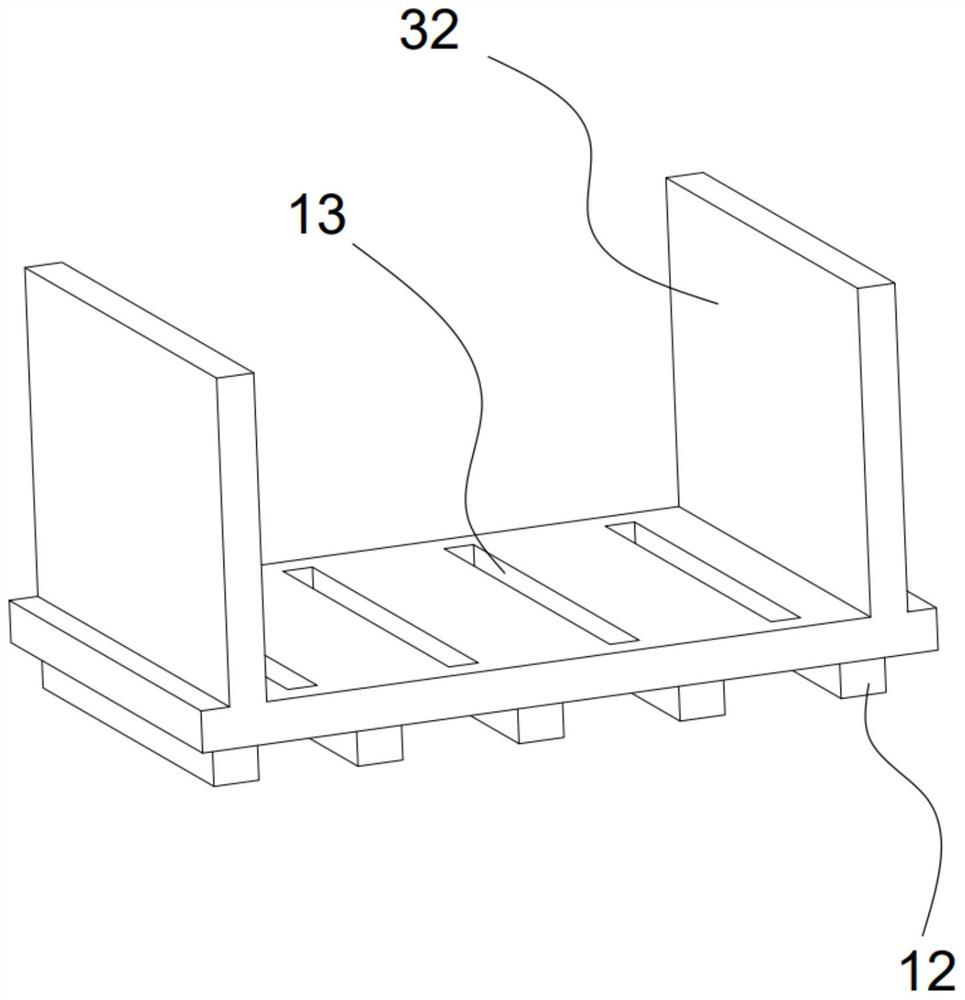

[0022] see Figure 1-3 , a surface polishing device for an elevator car door panel, comprising a support frame 1, a biaxial motor 14 is fixed on the support frame 1, and a translation mechanism is connected to the biaxial motor 14, and a translation mechanism for aligning the door panel is fixed on the translation mechanism. 11, the clamping seat 18 for clamping at the end, the locking stud 35 for clamping the door panel 11 is screwed on the clamping seat 18, the driving motor 6 is fixed on the support frame 1, and the driving The motor 6 is driven and connected with a stretching mechanism, and a horizontal plate 22 is installed at the bottom of the stretching mechanism, and a polishing mechanism for polishing the door panel 11 is provided at the bottom of the horizontal plate 22 .

[0023] The two clamping holders 18 provided in this device are clamped from both ends of the door panel 11, and the door panel 11 is locked and fixed by screwing the locking studs 35. Seat 18 car...

Embodiment 2

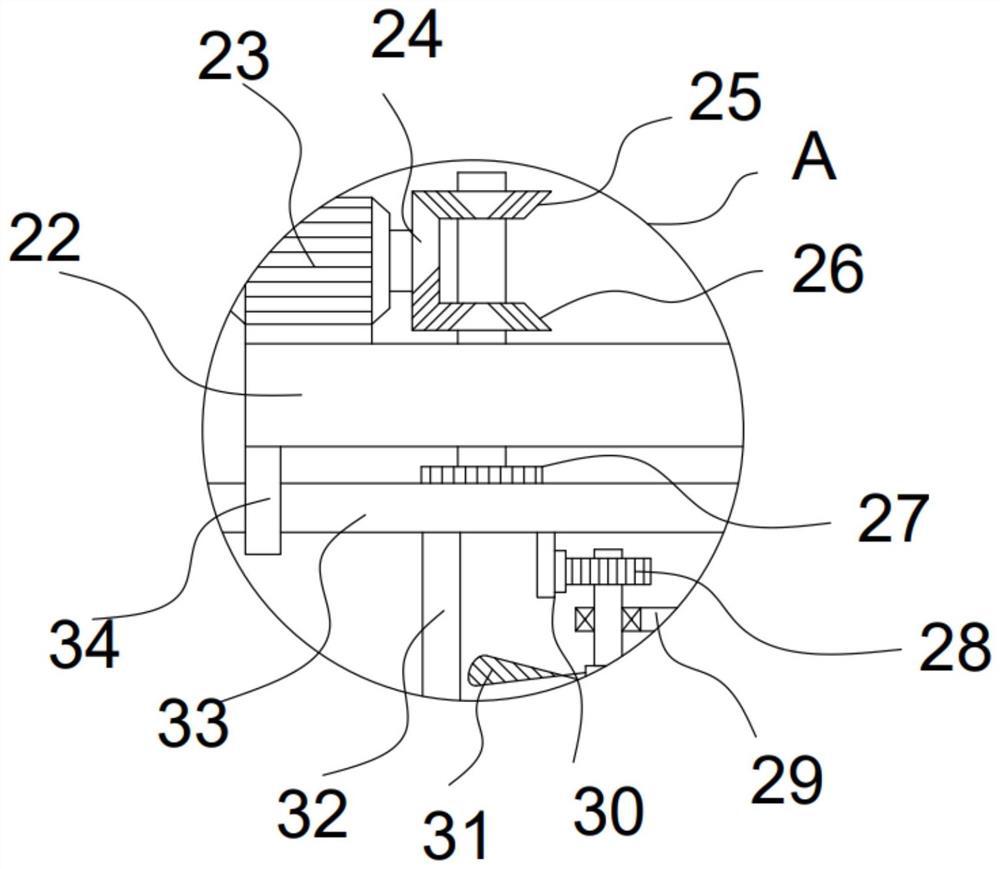

[0030] On the basis of Embodiment 1, in addition, the polishing mechanism of this device comprises the servo motor 23 that is fixed on the horizontal plate 22, and the servo motor 23 is driven and connected with incomplete bevel gear 24, and the incomplete bevel gear 24 is alternately meshed and connected with The bevel gear I25 and the bevel gear II26 are coaxially fixed, and the bottom of the bevel gear II26 is fixed with a transmission gear 27. The transmission gear 27 is meshed with a reciprocating rack 33, and the reciprocating rack 33 is covered with a gear fixed on the bottom of the horizontal plate 22. The limiting sleeve plate 34. The polishing mechanism also includes a polishing motor 10 fixed on the bottom of the reciprocating rack 33. The polishing motor 10 is driven to be connected with a rotating plate 29, and the rotating plate 29 is equipped with a planetary gear 28, and the bottom of the reciprocating rack 33 is fixed with a planetary gear. 28 meshing ring gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com