Ventilation type tool management device for numerical control machine tool

A tool management, CNC machine tool technology, applied in the direction of manufacturing tools, metal processing machinery parts, protection and storage accessories, etc., can solve the problem of inconvenient tool movement, etc. The effect of storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

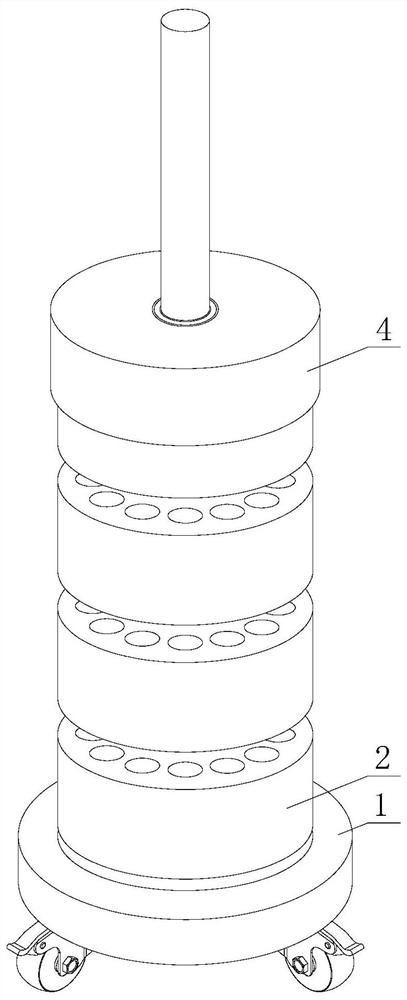

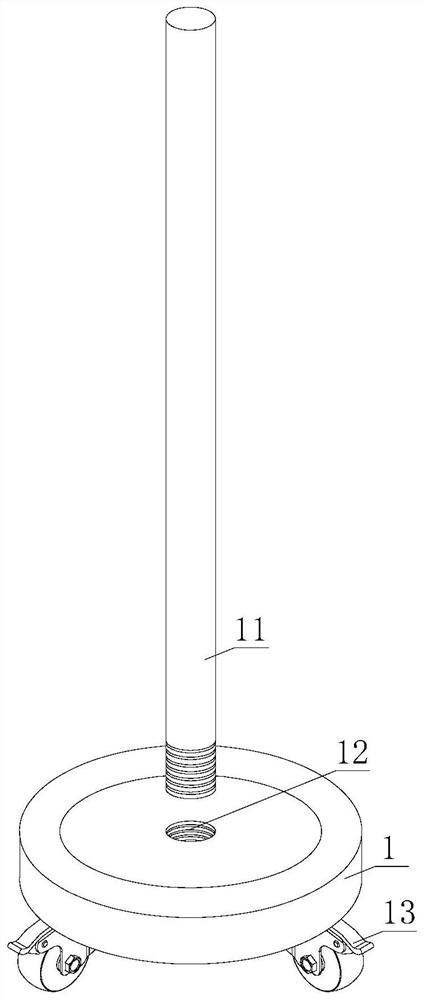

[0038] see Figure 1-Figure 2 , a ventilated tool management device for numerically controlled machine tools, comprising a movable base 1, a fixed sleeve rod 11 is arranged above the movable base 1, and a placement assembly 2 is socketed on the fixed sleeve rod 11 above the movable base 1, and the placement assembly 2 The ejection device 3 is installed inside, the protective device 4 is installed above the placement component 2, and multiple sets of placement components 2 are set, and the multiple sets of placement components 2 are all socketed on the fixed sleeve rod 11, and the top end of the fixed sleeve rod 11 is sleeved with a protective device 4. A plurality of sets of universal wheels 13 are installed under the movable base 1. An installation notch 12 is provided at the center above the movable base 1. The bottom end of the fixed sleeve rod 11 is set in the installation notch 12. The inside of the installation notch 12 is connected with the fixed sleeve. The bottom end ...

Embodiment 2

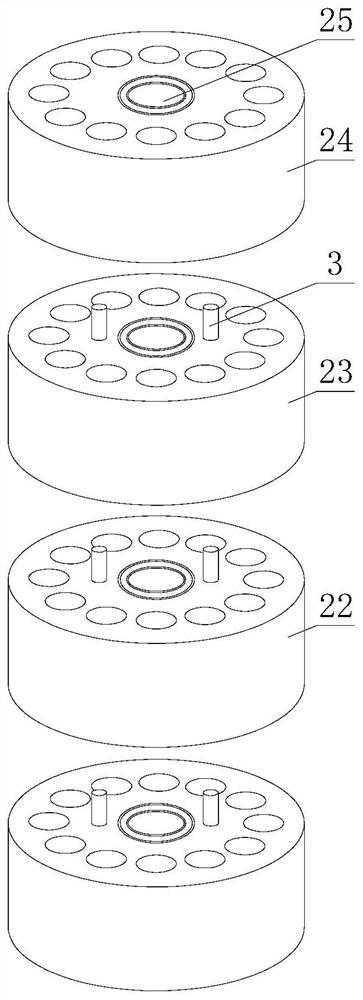

[0044] see Figure 11 , a ventilated tool management device for a numerically controlled machine tool, comprising a movable base 1, a placement assembly 2 is socketed on the movable base 1, multiple sets of placement assemblies 2 are provided, and multiple sets of placement assemblies 2 are socketed on the movable base 1, There are many groups of universal wheels 13 installed under the movable base 1, and the placing assembly 2 includes a first placing ring seat 21, a second placing ring seat 22, a third placing ring seat 23, a fourth placing ring seat 24 and a movable bearing 25, The first place ring seat 21, the second place ring seat 22, the third place ring seat 23 and the center of the fourth place ring seat 24 are provided with movable bearing 25, the first place ring seat 21, the second place ring seat 22, the second place ring seat 24 The third placement ring seat 23 and the fourth placement ring seat 24 are movably socketed on the fixed sleeve rod 11 through the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com