Double-station switching device for vertical take-up machine

A technology of switching device and double station, applied in the field of double station switching device, can solve the problems such as the large difference in weight between the full wire take-up reel and the empty take-up reel, the large eccentric load of the turntable shaft, and the plastic deformation of the turntable shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

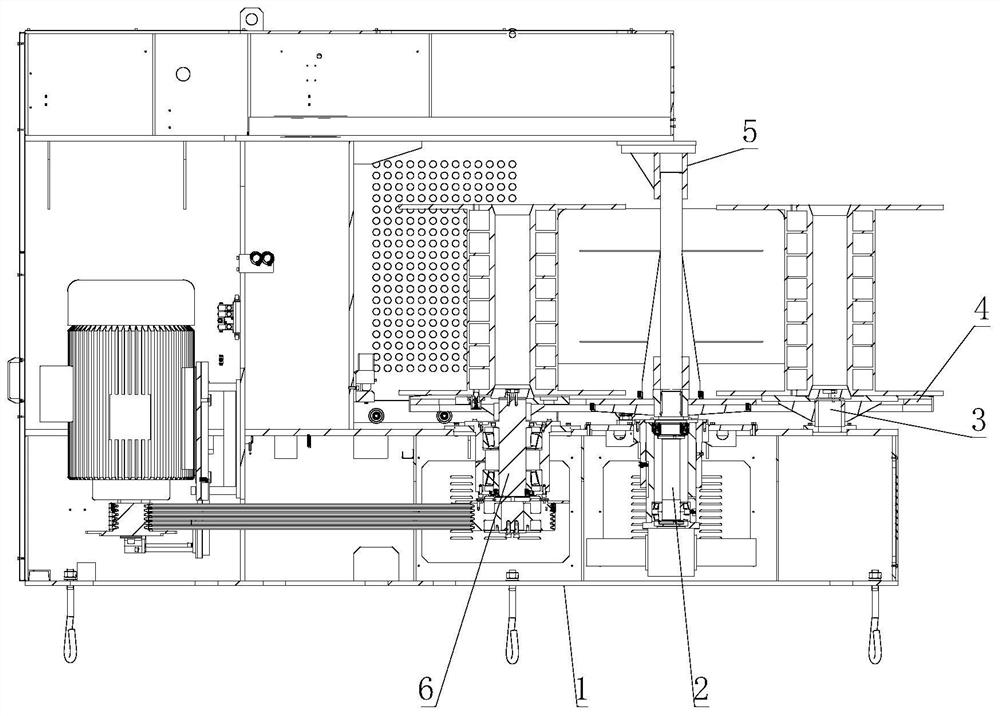

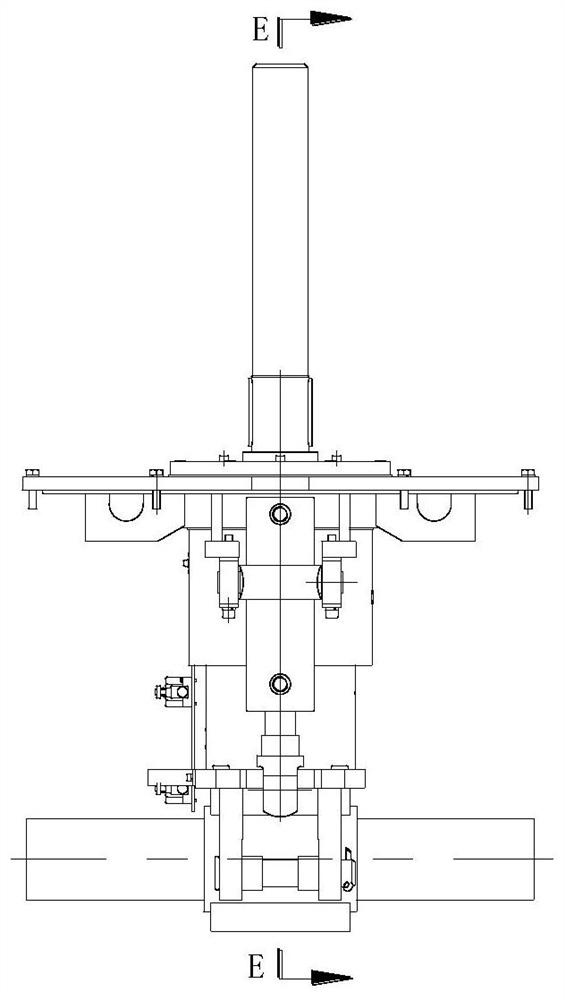

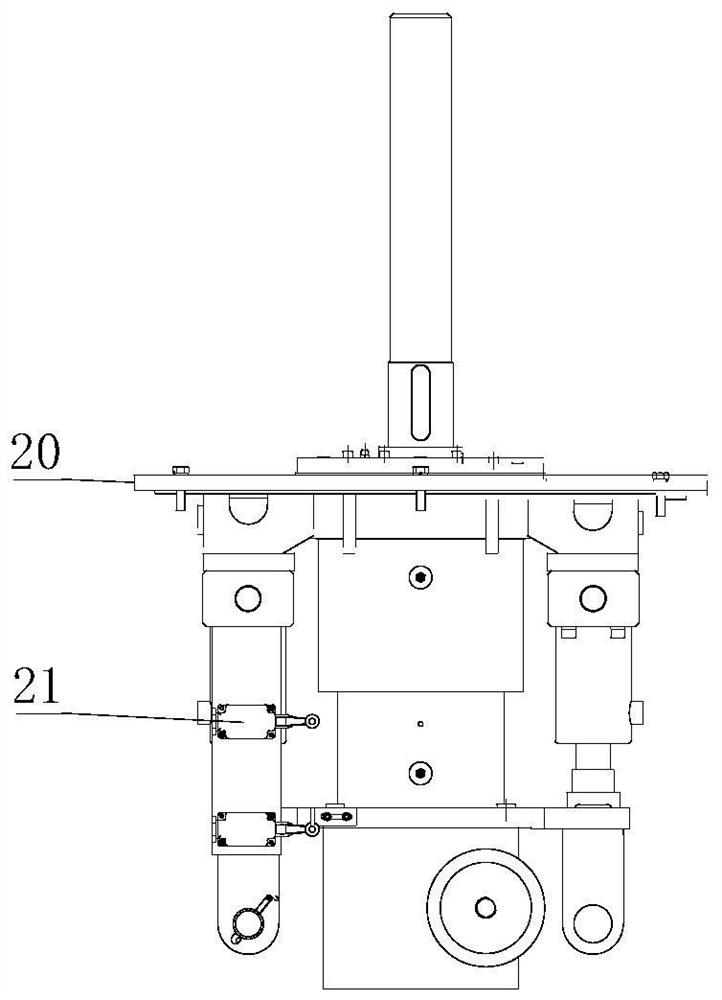

[0033] Such as Figure 1 to Figure 9 As shown, a double-station switching device of a vertical wire take-up machine according to the present invention includes a frame 1, a lifting and rotating mechanism 2 and a pallet assembly 4, and one end of the lifting and rotating mechanism 2 is fixedly installed on the frame 1, the other end is movably connected with the frame 1 through a balance assembly 5, and the pallet assembly 4 is movably fitted in the middle of the lifting and rotating mechanism 2. The lower end of the lifting and rotating mechanism 2 is fixedly installed on the frame 1, and the upper end is movably connected with the frame 1 through the balance assembly 5, and the unbalanced load effect on the lifting and rotating mechanism 2 is reduced through the balance assembly 5, which helps to reduce the load on the lifting and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com