Design Method of Offset Cam Type Intake Control Mechanism

A technology of offset cam and control mechanism, which is applied in calculation, instrumentation, geometric CAD, etc. It can solve the problems of difficult installation of cam mechanism, poor reliability, large arm operation space, etc., and achieve the function of small moment arm and large torque and compact structure Performance requirements, reduce the effect of partial load, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

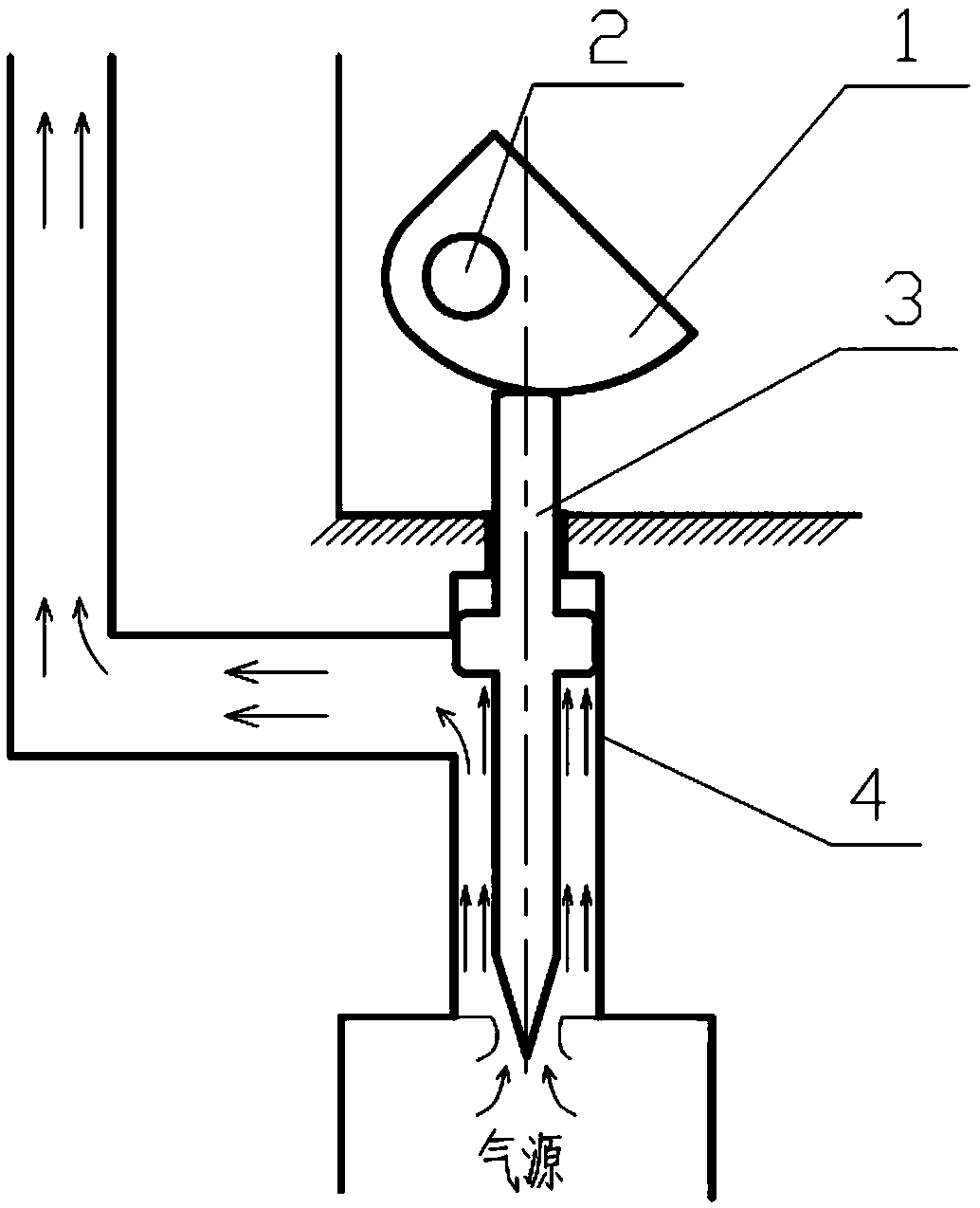

[0026] See details Figure 1a-Figure 1b , an optimal design method of an offset cam air intake control mechanism, adopting an offset cam structure in which the cam 1 and the camshaft 2 are integrated, and driving the thimble 3 to move linearly along the guide groove 4 through the cam surface to optimize the cam eccentricity Contact the curved surface with the thimble, so that the cam surface drives the thimble to meet the principles of thrust equivalence and eccentric load balance, and realize the function of small moment arm and large torque, which is easy to install in a narrow space. The specific design scheme is as follows:

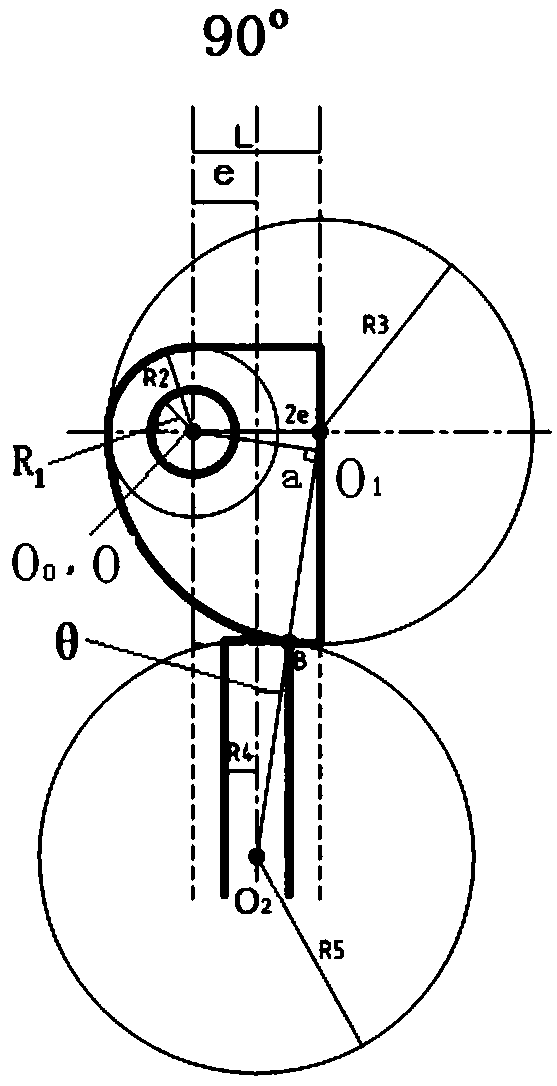

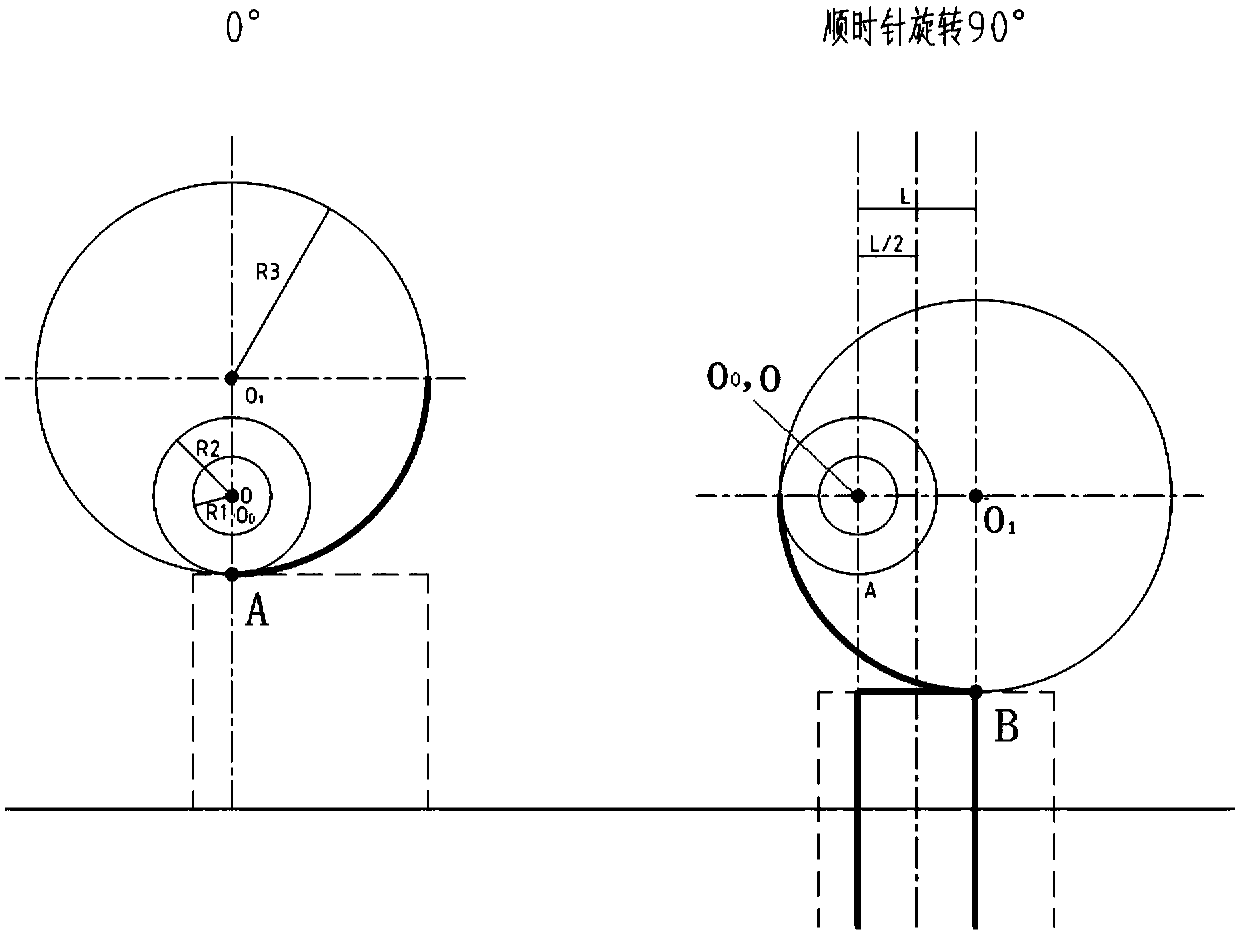

[0027] see attached figure 2 And attached image 3

[0028] 1. Determine the maximum stroke of the thimble

[0029] 1) Determine the camshaft cylinder radius R1 and the cam base circle radius R2 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com