Instrument surface rapid cleaning equipment for clinical laboratory

A technology for cleaning equipment and inspection departments, applied in lighting and heating equipment, cleaning methods using liquids, chemical instruments and methods, etc., which can solve problems such as inability to dry in time and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

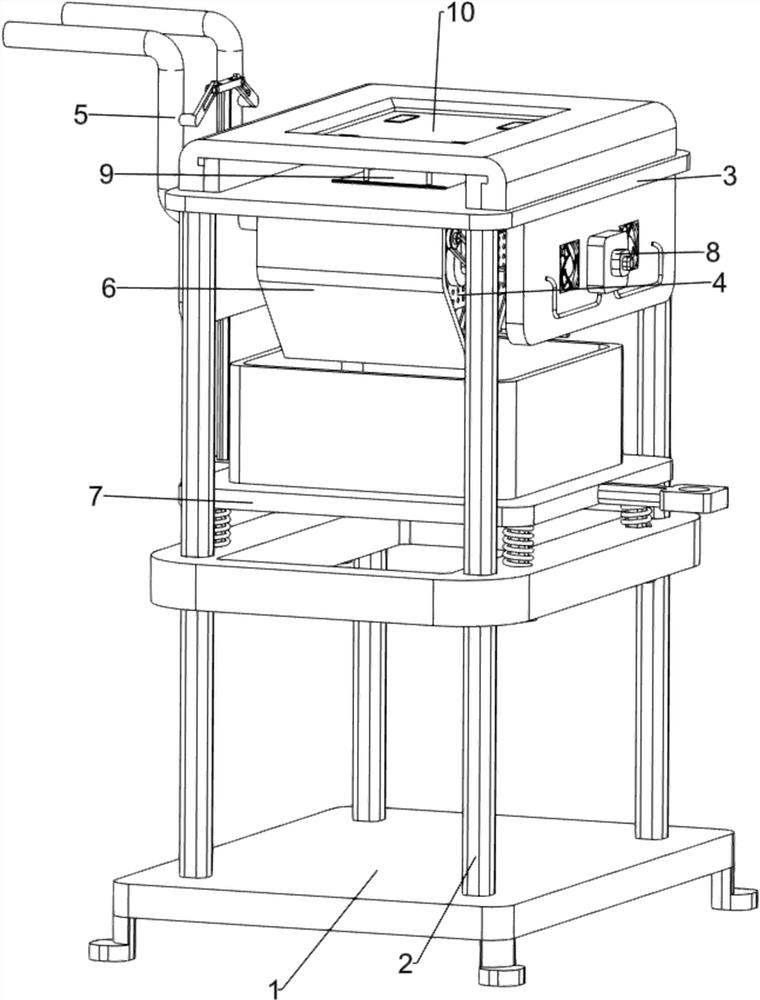

[0064]A fast cleaning equipment for inspection techniques, such asfigure 1 As shown, a base 1, a frame 2, a table 3, a jitter mechanism 4, and a manual control watering mechanism 5 are provided, and a frame 2 is provided on the base 1, a table 3 is provided at the top of the frame 3, top of the workbench 3. The inner wall is provided with a jitter mechanism 4, and there is a manual control watering mechanism 5 on the left side of the table 3.

[0065]When the inspector needs to quickly clean the instrument surface of the inspection department, this cleaning device can first be placed in the jitter mechanism 4, and the jitter mechanism 4 is activated to swing left and right, then open manual control. The valve of the water spray mechanism 5, the water is injected into the jitter mechanism 4 from manual control watering mechanism 5, and the effect of cleaning the instrument is achieved. After cleaning, the jitter mechanism 4 and the manual controlling the valve of the watering mechanism ...

Embodiment 2

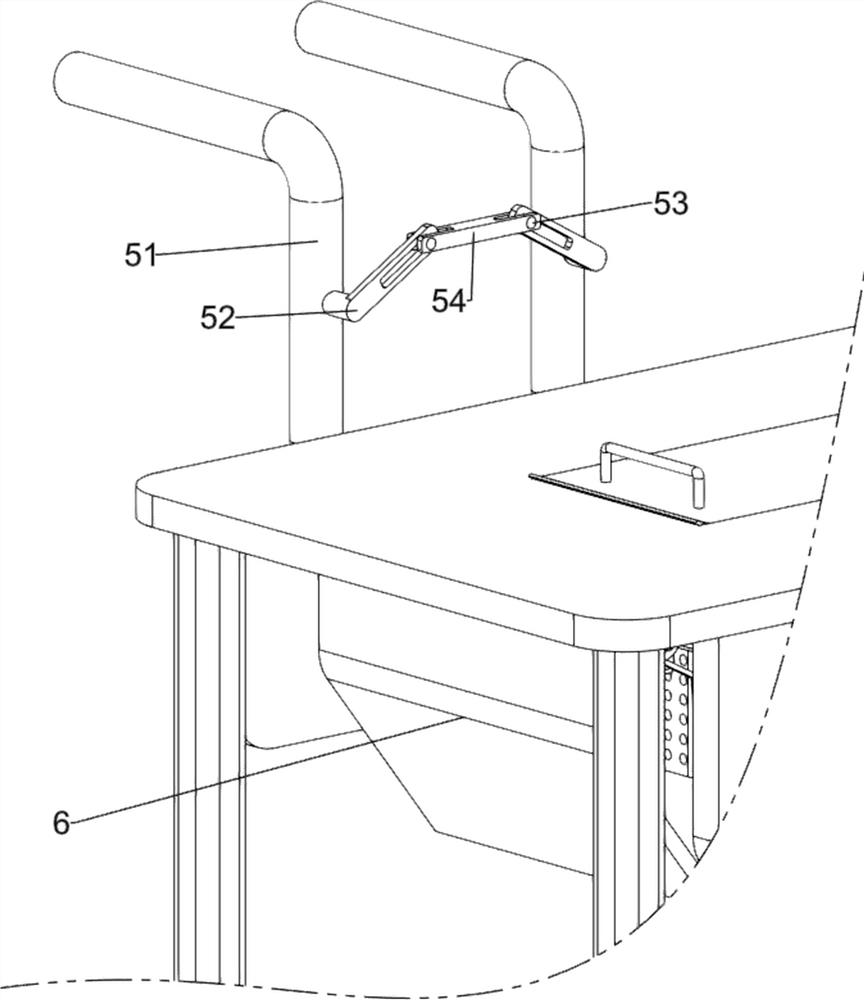

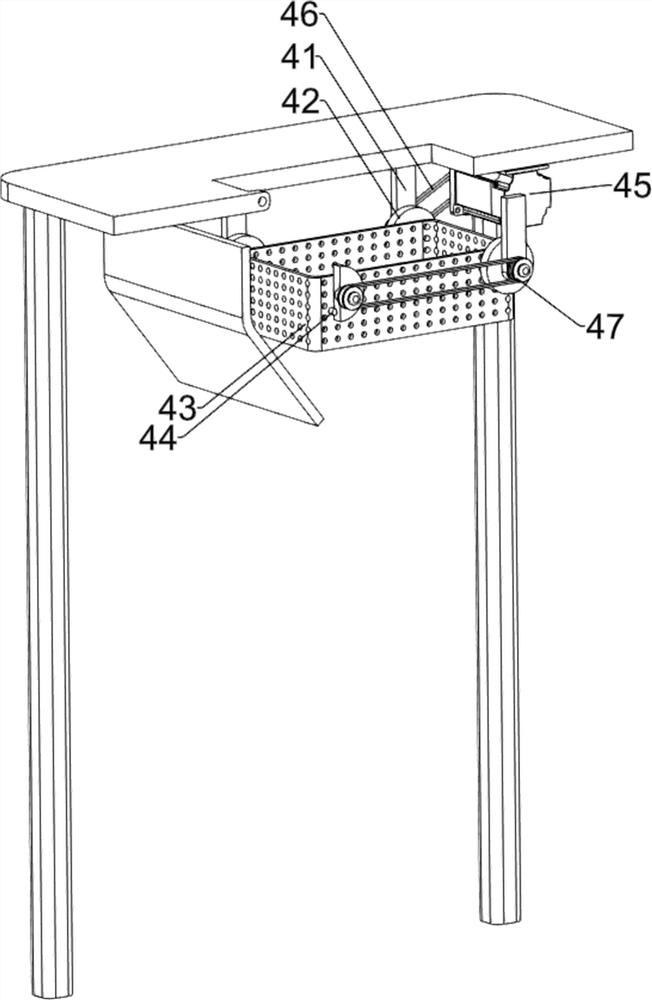

[0067]On the basis of Example 1, such asfigure 2 withimage 3 As shown, the jitter mechanism 4 includes a first bracket 41, a turntable 42, a filtration frame 43, a restricted rod 44, a motor 45, a first belt 46, and a second belt 47, and the inner wall of the table 3 front and after the left and right side. There is a first bracket 41, the lower rotation of the first bracket 41 is provided with a turntable 42, and the inner wall eccentric position of the turntable 42 is provided with a resigning rod 44, and there is a filter frame 43 between the four restricted rods 44, and the inner wall of the table 3 is in front of the table 3 The motor 45 is mounted on the side, and the first belt 46 is connected between the output shaft and the rotating plate 42 of the right side front portion, and the second belt 47 is connected between the two turntable 42 on the left.

[0068]The worker put the instrument to be cleaned into the filtration frame 43, activates the motor 45, and the motor 45 outpu...

Embodiment 3

[0072]On the basis of Example 2, such asFigures 4 to 7As shown, there is also a guide plate 6, and a fluid board 6 is provided on both sides of the inner wall of the table 3 bottom.

[0073]The filtration frame 43 constantly jitter makes water flowers, and the flow of these water flowers can be splashed down by water.

[0074]Also included, a gravity control watering mechanism 7, the gravity control watering mechanism 7 includes a second link 71, a second spring 72, a load plate 73, a handle 74, and a water storage frame 75, and the rack 2 is around and left. The sliding type is provided with the second link 73 between the top end of the four second links 71, and the second link 72 is connected to the second spring 72, and the second spring 72 is connected to the load plate 73. The second spring 72 is connected to the rack 2, and the upper portion of the load plate 73 is provided with a handle 74. The top portion of the load plate 73 is provided with a water storage frame 75, and a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com