Device for rapidly preparing conductive carbon

A conductive carbon and equipment technology, which is applied in the field of rapid preparation of conductive carbon equipment, can solve the problems of affecting the crushing quality, difficult to clean, and blocking the feeding port, etc., and achieve the effect of easy transportation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with specific embodiments.

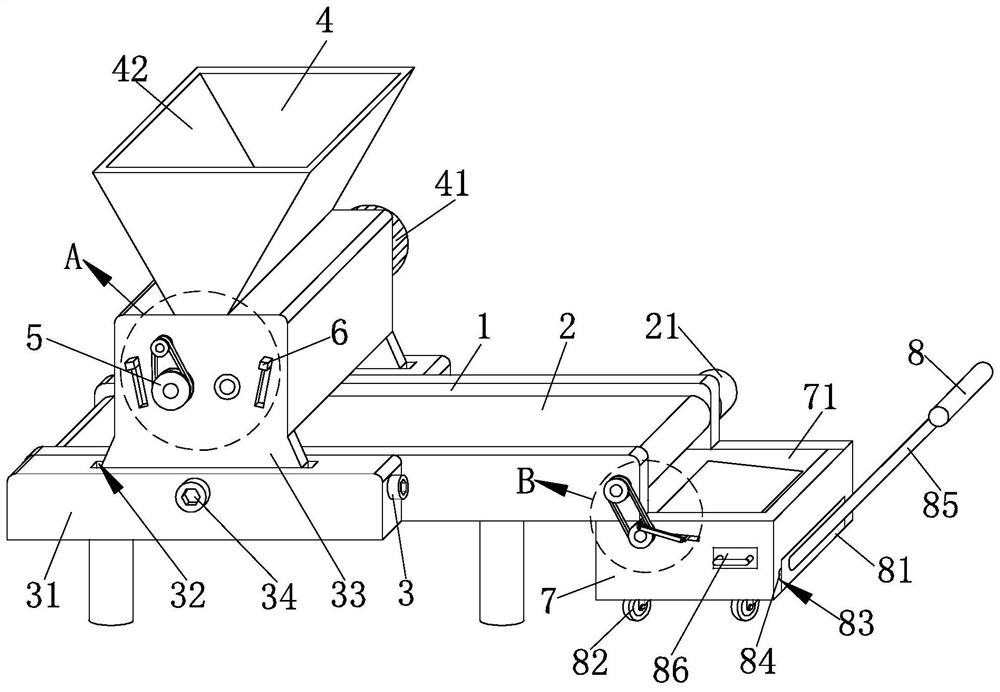

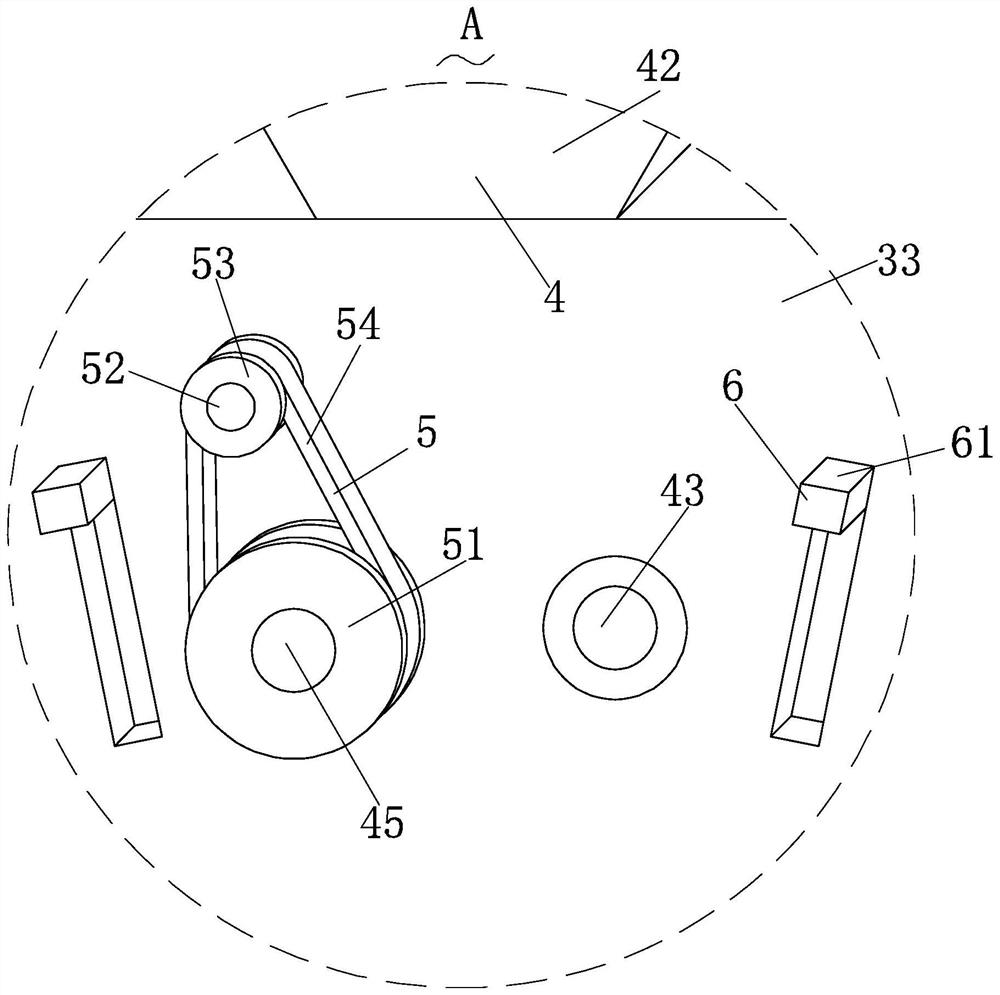

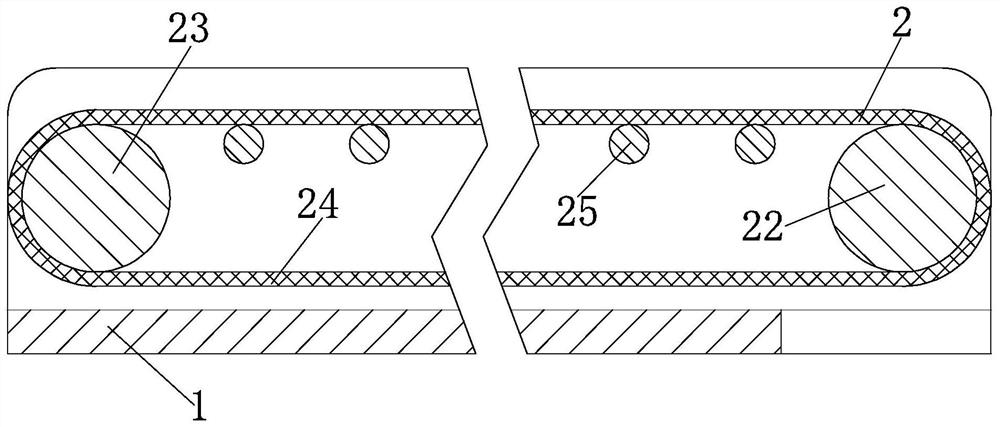

[0031]Such asFigure 1 - Figure 10As shown, the rapid preparation of a conductive carbon device according to the present invention includes a bracket 1, a conveying structure 2, a mounting structure 3, a pulverizing structure 4, an anti-blocking structure 5, a wiper, screen structure 7, and a collection structure 8. One end of the bracket 1 of the bracket 1 to support can be continuously transported to the conveyance structure 2, at one end setting of the stent 1, can facilitate the mounting assembly to mount the bracket 1. The mounting structure 3; the pulverizing structure 4 capable of thorling the carbon block at one end of the mounting structure 3, at one end of the mounting structure 3, can be jittering the feed port to prevent the material blocking feed The anti-blocking struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com