Preparation method of MOFs-PVDF composite ultrafiltration membrane

An ultrafiltration membrane, mofs-pvdf technology, applied in the field of preparation of MOFs-PVDF composite ultrafiltration membrane, can solve the problems of many bacteria and microorganisms, the composite ultrafiltration membrane does not have bactericidal function, and threatens the health of drinking water, so as to achieve anti-pollution Strong ability, excellent bactericidal performance, and the effect of improving bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

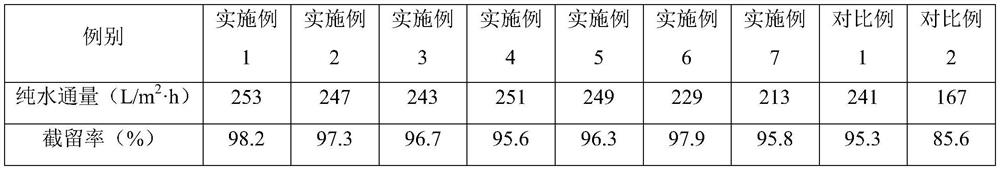

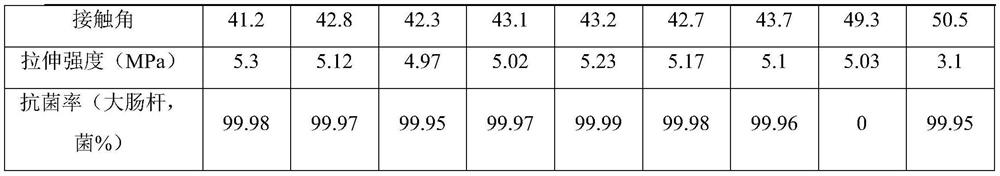

Examples

preparation example Construction

[0032] 1. Preparation of hydroxyl-containing PVDF

[0033] The preparation method of the hydroxyl-containing PVDF can refer to CN107626216A. details as follows:

[0034] The PVDF is firstly treated with lye, and then the PVDF treated with lye is reacted in the isopropanol solution of sodium borohydride. After the reaction is completed, the PVDF is filtered and dried to obtain PVDF containing hydroxyl groups.

[0035] Specifically, the lye is an aqueous lithium hydroxide solution with a mass fraction of 3%; the reaction conditions for the lye treatment are: stirring and reacting at 25-60° C. for 36-72 hours.

[0036] Specifically, the mass fraction of the isopropanol solution of sodium borohydride is 0.1-1.5%, more preferably 0.2%; the reduction reaction conditions in the isopropanol solution of sodium borohydride are: stirring reaction at room temperature 18-36h.

Embodiment approach

[0037] According to some embodiments provided by the present invention, the preparation of the hydroxyl-containing PVDF specifically includes: immersing 50g of PVDF in an aqueous solution of 200g of lithium hydroxide (3% by mass fraction), stirring at 50°C for 48h, and then respectively using water (2000mL ) and isopropanol (2000mL) for washing; then the washed PVDF was added to 200g of sodium borohydride in isopropanol (0.2% by mass fraction), stirred at room temperature for 24h, filtered, and dried to obtain hydroxyl-containing PVDF .

[0038] 2. Preparation of modified MOFs materials

[0039] Add the MOFs material to the aqueous solution containing ferric nitrate and silver nitrate, stir and mix to obtain the precursor solution;

[0040] Add sodium hydroxide solution to the above precursor solution, stir, pass through oxidizing gas, filter, and dry to obtain the modified MOFs material loaded with AgO and FeOOH.

[0041] Preferably, the MOFs material is one of ZIF-8, MIL-1...

Embodiment 1

[0060] The preparation method of the MOFs-PVDF composite ultrafiltration membrane provided in this embodiment comprises the following steps:

[0061] (1) Preparation of modified MOFs materials

[0062] The MOFs material is ZIF-8, and in the obtained modified ZIF-8 material, the mass of AgO is 10% of the mass of ZIF-8, and the mass of FeOOH is 5% of that of ZIF-8.

[0063] Composition according to the above ratio, weigh Fe(NO 3 ) 3 and AgNO 3 Dissolve in water, stir for 30 minutes; then add ZIF-8, stir at room temperature for 1.5 hours to obtain a precursor solution;

[0064] Add mass fraction to the precursor solution and be 8% NaOH solution, stir again 15min; Pass into O then 2 / N 2 mixed gas, and continued to stir for 30 min, filtered and washed, and dried in vacuum at 60 °C for 4 h to obtain a modified ZIF-8 material loaded with AgO and FeOOH.

[0065] (2) Preparation of MOFs-PVDF composite ultrafiltration membrane

[0066] Based on the total mass of the casting solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com