Printed circuit board and manufacturing method of printed circuit board

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., and can solve the problems of lack of installation and protection mechanisms, insufficient stability of circuit boards, and high manufacturing costs of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

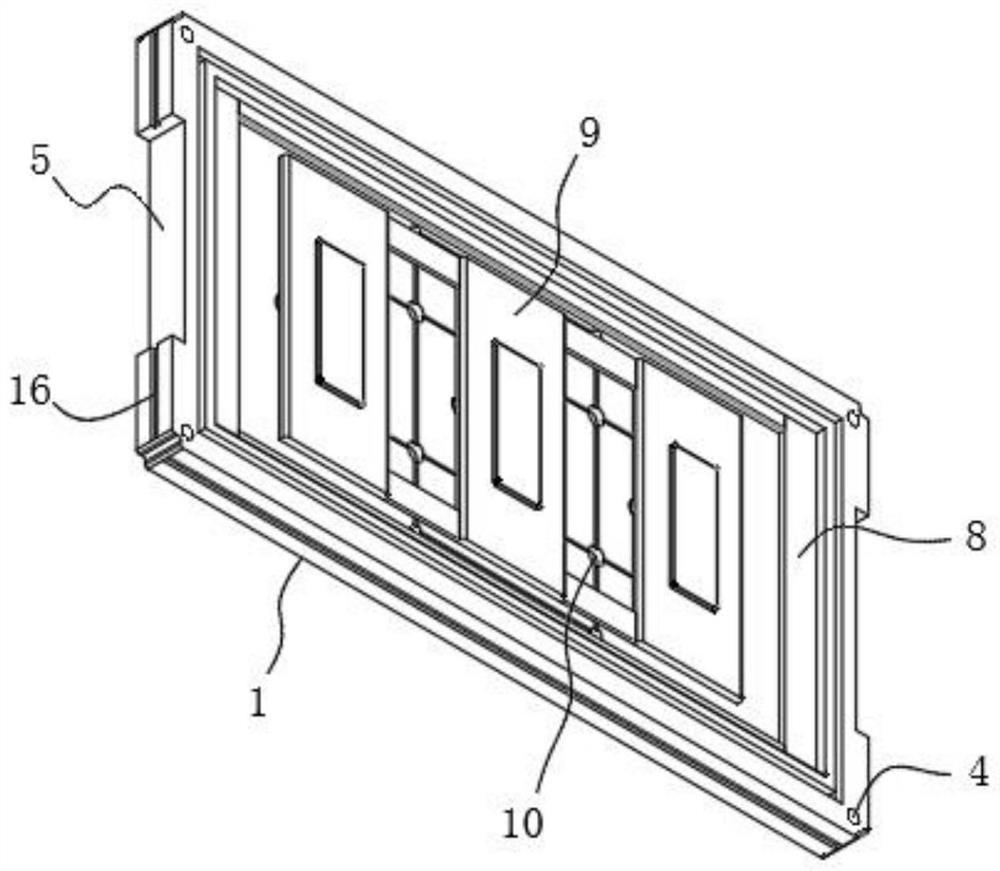

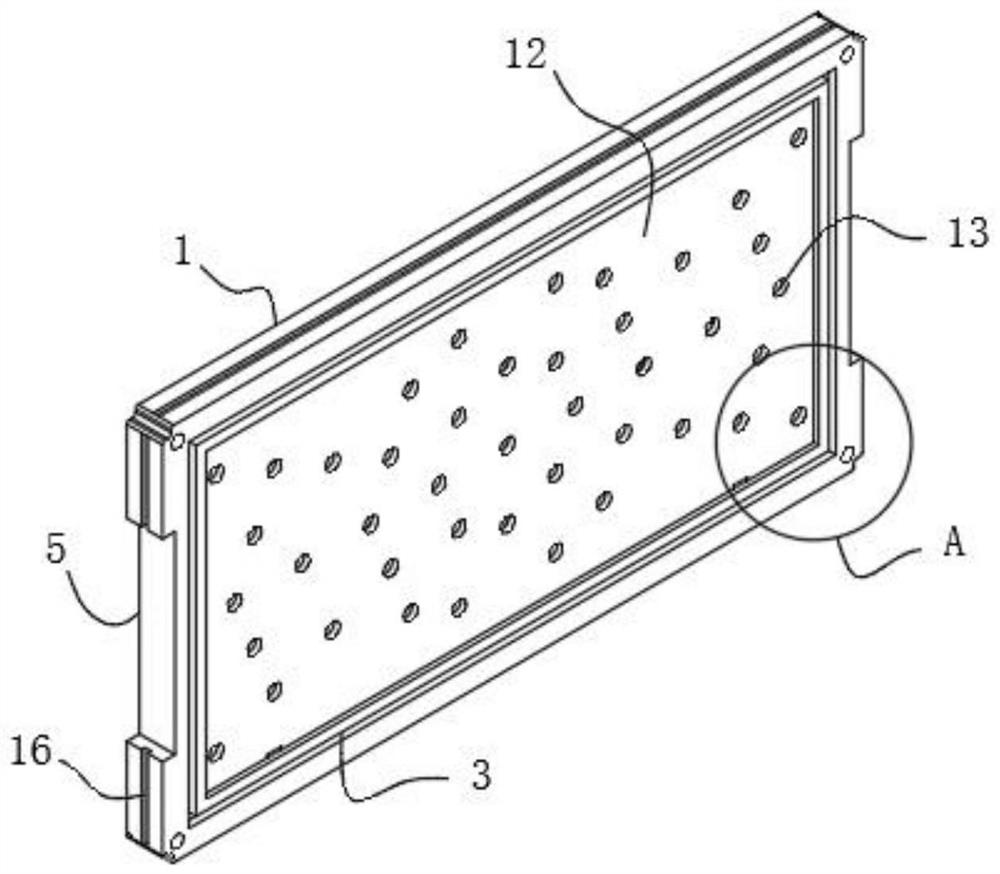

[0039] Please refer to Figure 1-6 Shown: a printed circuit board, including a substrate 1, a first mounting surface 2 and a second mounting surface 3, the two opposite surfaces of the substrate 1 are respectively provided with a first mounting surface 2 and a second mounting surface 3, which is convenient for the control module and For the construction of the protection mechanism, the core board 9 is installed on the surface of the first installation surface 2, and the surface of the first installation surface 2 is also provided with a conduction hole 10, and the inner surface of the conduction hole 10 is connected with a metal film 11, and the metal film 11 is connected with each control module. To form an electrical connection, the core board 9 is compatible with the metal film 11, which is convenient for the control module to form a control reaction effect. The side of the via hole 10 is connected with a slot-shaped hole 7, and the connection between the via hole 10 and the...

Embodiment 2

[0042] Please refer to Figure 7 Shown: a kind of manufacturing method of printed circuit board, comprises the following steps:

[0043] Step 1: Select the glass fiber board material that meets the usage standards and cut it;

[0044]Step 2: Draw the schematic diagram of the printed circuit board, and import the connection relationship and device information of the schematic diagram into the glass fiber board material;

[0045] Step 3: Process the glass fiber board material to obtain the substrate 1 of the printed circuit board, and groove the corresponding two surfaces of the substrate 1 to form two mounting surfaces;

[0046] Step 4: Lay the core board 9 and each slot hole on the first mounting surface 2 of the substrate 1 to form the required circuit connection. Specifically, each conduction hole 10 is laid with the slot-shaped hole 7 and connected to form 6 solder joints, more coherent, and maintain the use effect of printed circuit boards;

[0047] Step 5: Install prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com