Pesticide residue detection pretreatment system

A technology of pesticide residue detection and nitrogen blowing, which is applied to the analysis of materials and instruments, and can solve problems such as environmental pollution and safety hazards of on-site workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

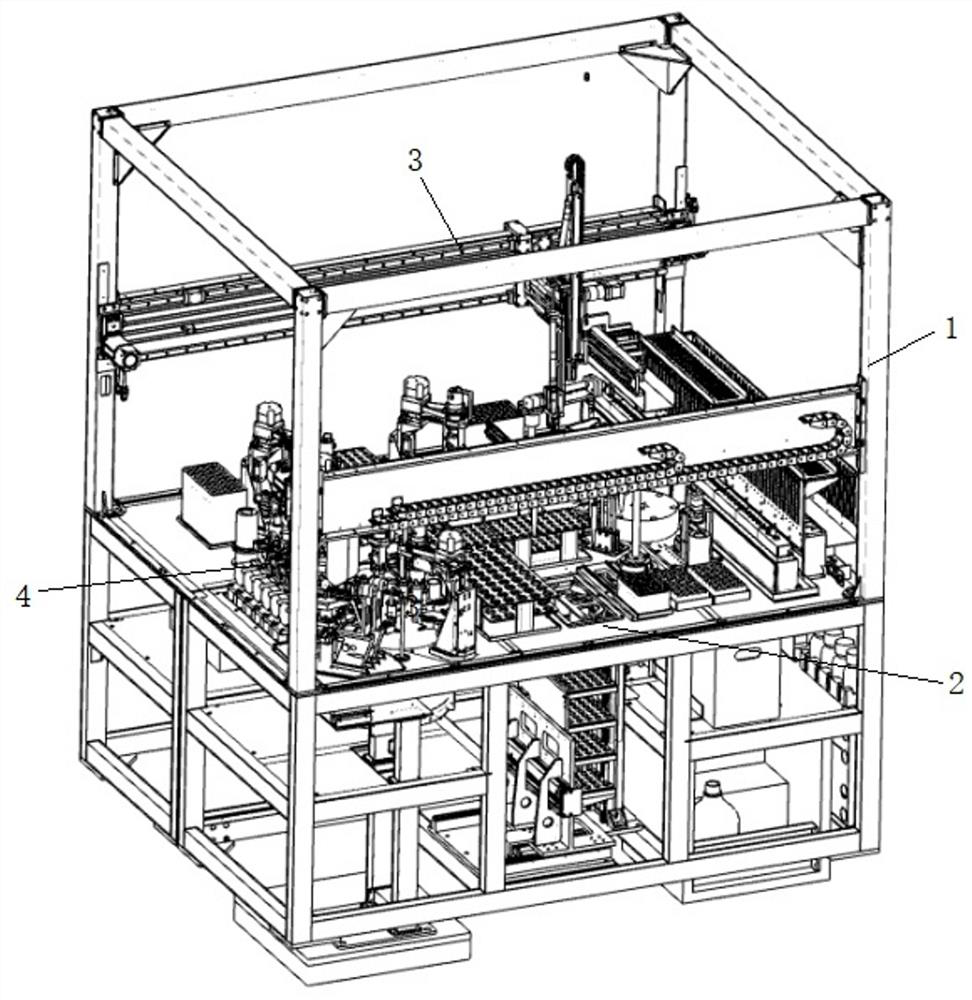

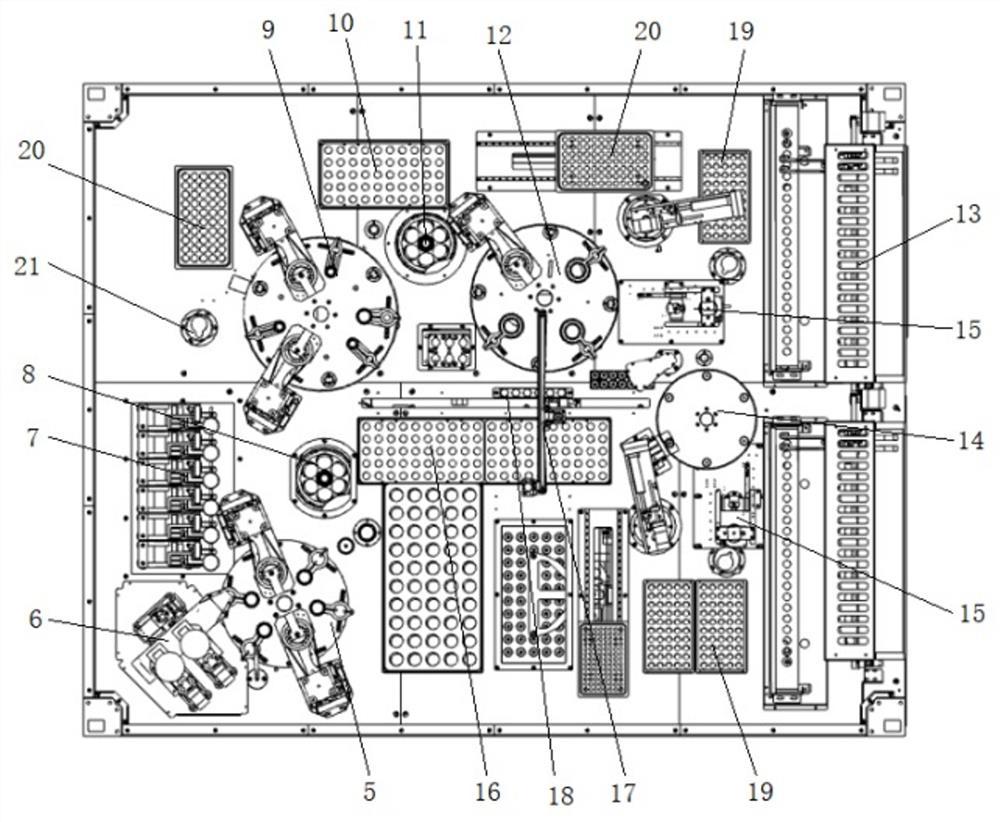

[0034] The specific implementation of the pesticide residue detection pretreatment system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] See attached figure 1 , the pretreatment system for pesticide residue detection is composed of a steel structure frame 1, a workbench 2 is in the middle of the frame 1, a functional unit 4 is arranged above the workbench 2, a mechanical arm unit 3 is arranged on the frame 1, and a workbench 2 is arranged below Cable and pipe layout for circuit air circuit, and waste connection device. The X-axis of the slide rail of the mechanical arm unit 3 is installed on the front and rear sides of the frame 1, and a plurality of mechanical arms are arranged on it, which are divided into a gripper mechanical arm and a pipetting mechanical arm.

[0036] The top of the frame 1 is semi-sealed, and a ventilation mechanism is set on it. There are input and output positions at the front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com