Concrete impact resistance detection equipment

A detection equipment and concrete technology, applied in the field of impact resistance detection equipment, can solve the problems of inaccurate detection results, less manual participation, waste of time, etc., and achieve the effects of improving detection efficiency, good cleaning effect, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

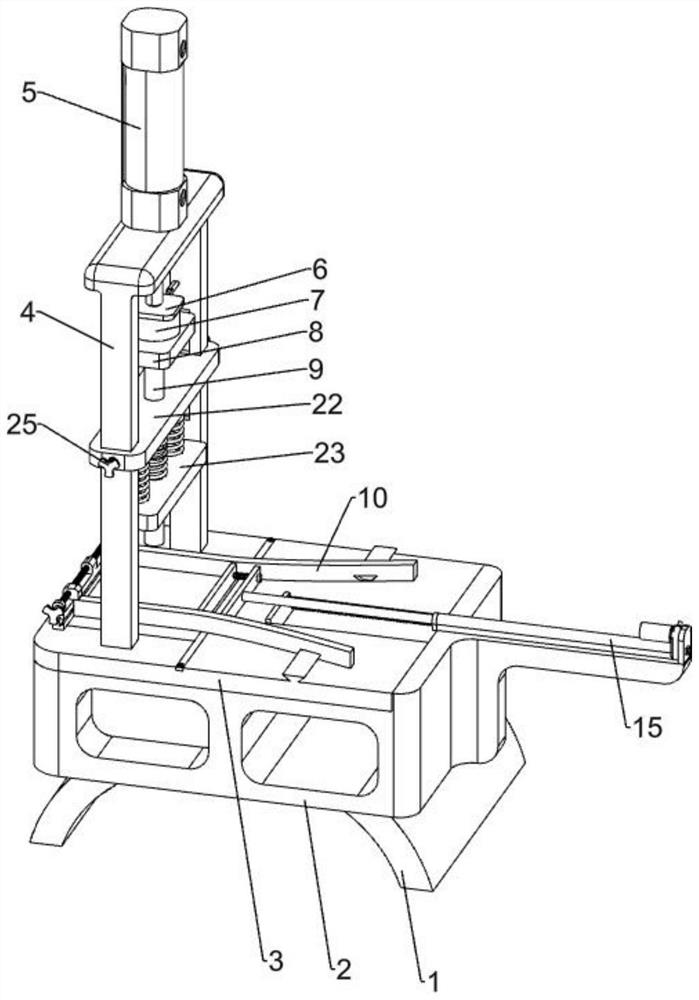

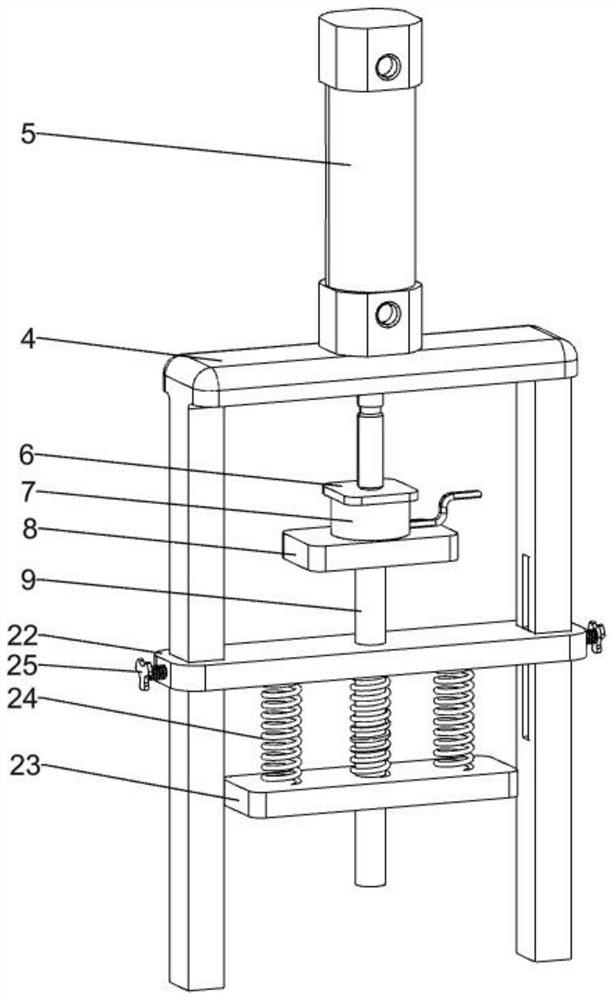

[0025] A concrete impact testing equipment, such as Figure 1-4 As shown, it includes a table leg 1, a base 2, a base plate 3, a bracket 4, an impact device, a clamping device and a pushing device, the base 2 is fixedly installed on the table leg 1, the base plate 3 and the bracket 4 are fixedly installed on the base 2 Fixedly installed on the upper left side of the base plate 3, the impact device is installed on the bracket 4, the clamping device is installed on the upper left side of the base plate 3, the clamping device is below the impact device, the pushing device is installed on the upper right side of the base plate 3, and the pushing device On the right side of the clamping device.

[0026] The table leg 1 plays a supporting role for the whole device, the bottom plate 3 plays a supporting role for the bracket 4, and the base 2 plays a supporting role for the whole device. When testing the strength of building concrete, the impact device is raised first, and then the re...

Embodiment 2

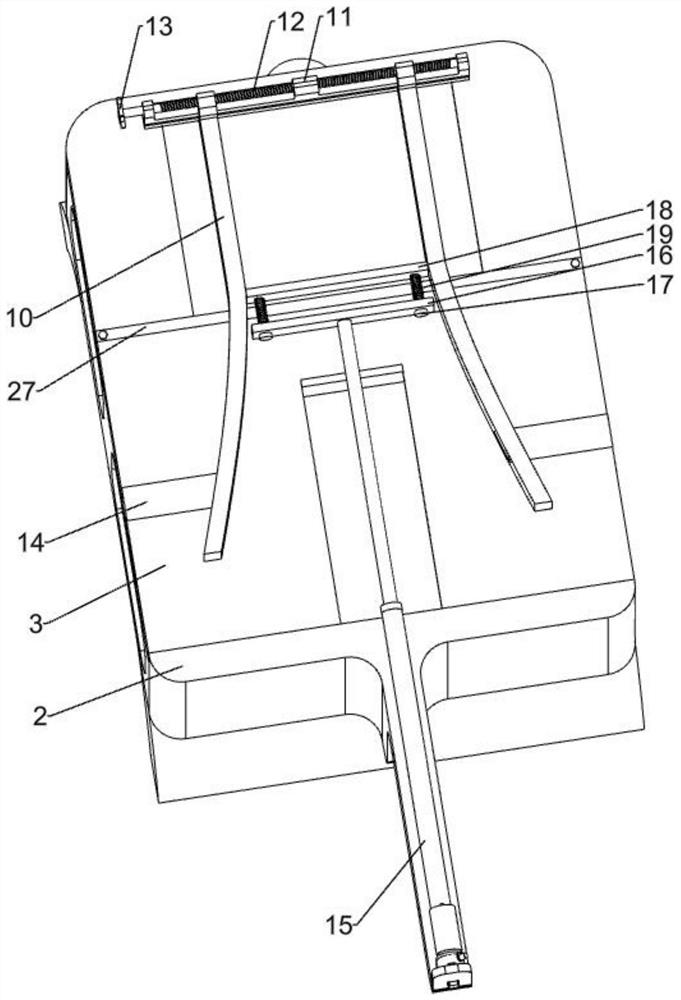

[0034] On the basis of Example 1, such as figure 2 , Figure 5-7As shown, also include slide plate 20, baffle plate 2001, second spring 21 and scraper 27, have two rectangular holes on the base plate 3, the left end of slide plate 20 is under the left side rectangular hole, the right end of slide plate 20 is on the right side Under the rectangular hole, the slide plate 20 is slidingly connected with the base plate 3, the baffle plate 2001 is installed on the upper right side of the slide plate 20, the baffle plate 2001 is higher than the base plate 3, and four second springs 21 are fixedly installed between the right side of the slide plate 20 and the base plate 3 , the scraper 27 is installed on the right end of the left rectangular hole on the bottom plate 3, and the scraper 27 is in contact with the slide plate 20.

[0035] When the test is over, the electric push rod 15 will shrink back. During the shrinking process, the first push plate 16 will contact the baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com