An Alcohol Burning System Based on Engine Waste Heat Gasification of Methanol

An engine and methanol technology, applied in engine components, combustion engines, engine control, etc., can solve the problems of poor low-temperature starting performance and emission performance of methanol fuel engines, reduce the temperature and concentration of mixed gas, and improve the low-temperature cold start performance , Improve combustion and emission performance, increase the effect of concentration and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a detailed description of the technical solutions in the embodiments of the present application in combination with the drawings in the embodiments of the present application. The described embodiments are only used to explain the present invention, not to limit the present invention.

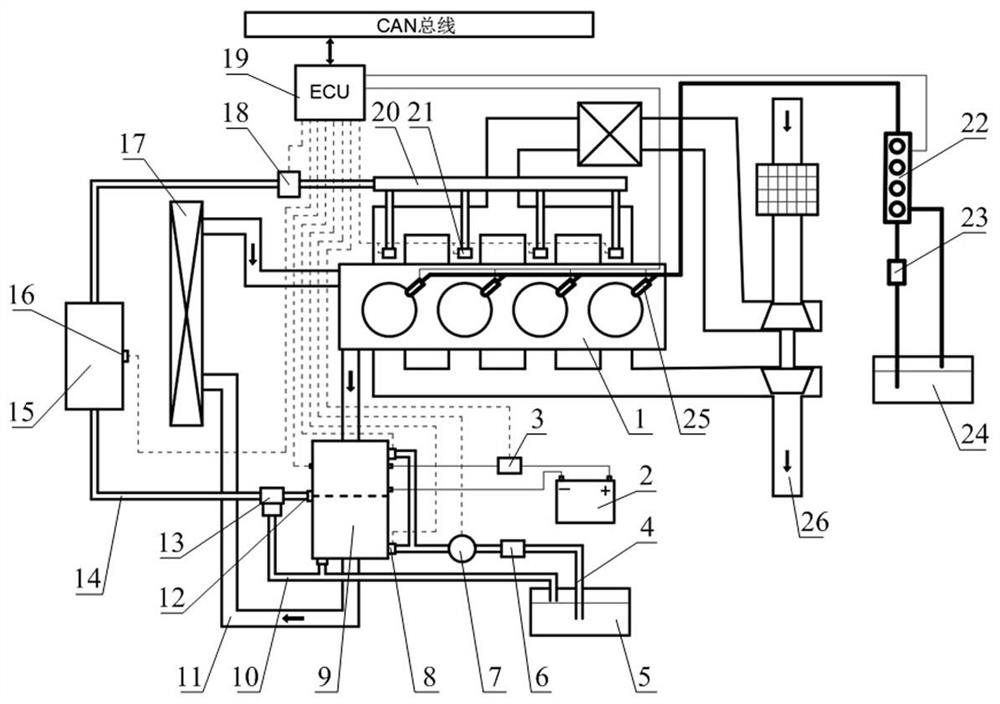

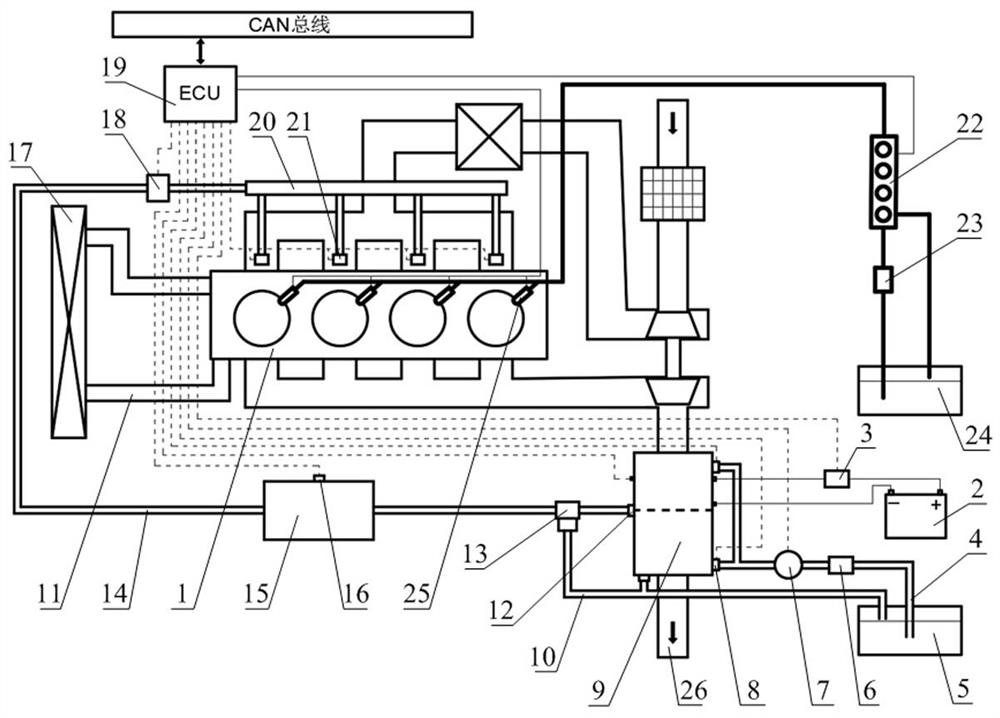

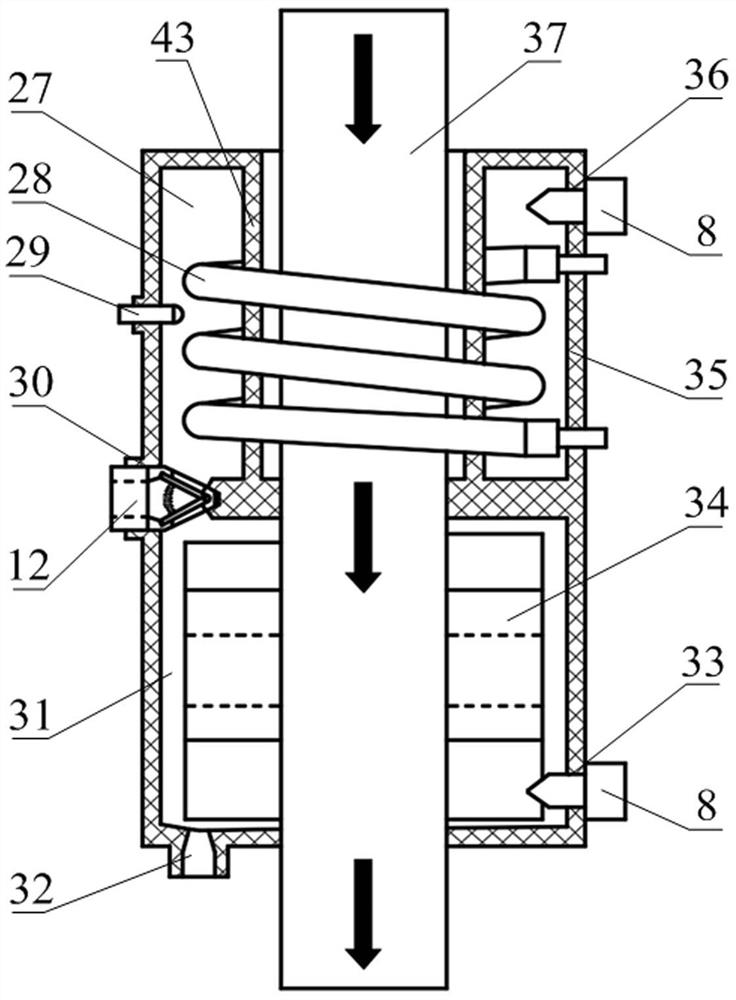

[0027] Such as figure 1 As shown, the embodiment of the present invention proposes an alcohol burning system based on engine waste heat gasification of methanol, which includes a diesel engine, a methanol supply system, a methanol gasification generator, a methanol vapor injection system and a control system.

[0028] The diesel engine 1 includes a complete diesel supply system, intake and exhaust system, cooling system and diesel injection system.

[0029]The methanol supply system includes a methanol tank 5 , a filter 6 and a methanol pump 7 , and each component is connected in sequence through an alcohol-resistant pipe 4 . The methanol tank 5 is used to store methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com