Premixing method of conductive glue, conductive adhesive tape and preparation method thereof

A conductive and glue technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of affecting the specific gravity of conductive particles, fast precipitation, solvent splashing, etc., to improve the wetting speed and stabilize the stirring process. , the effect of increasing the humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 5% of the total weight of the polyurethane glue BC-01 required for this production, add it to toluene and disperse it with a mixer until it is uniform to obtain the mixture A;

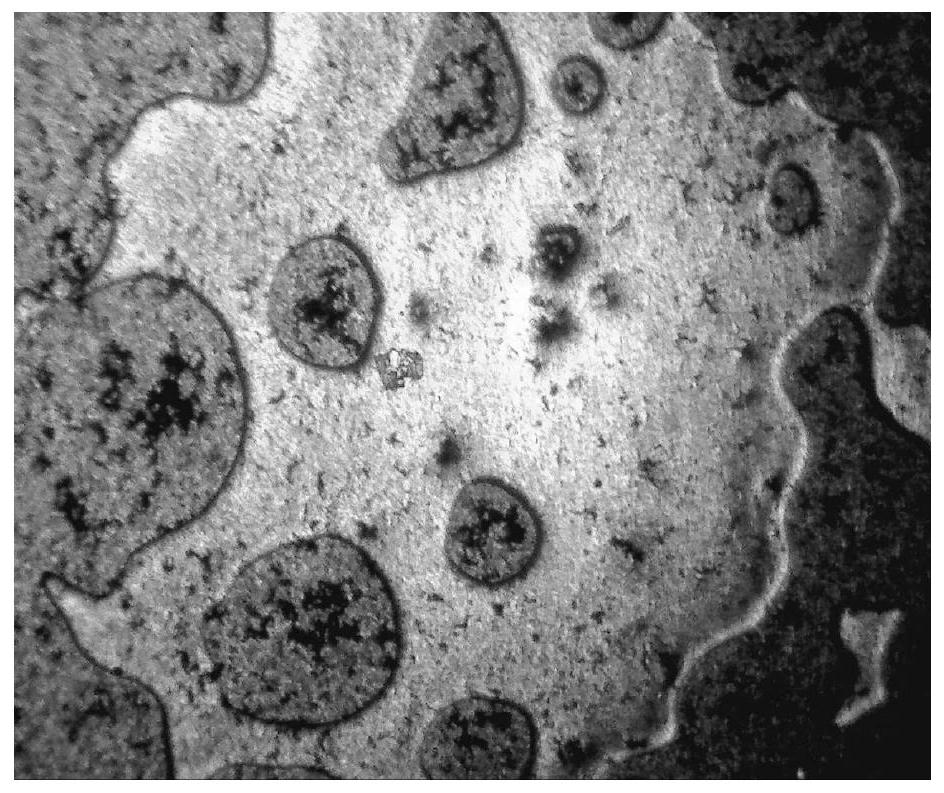

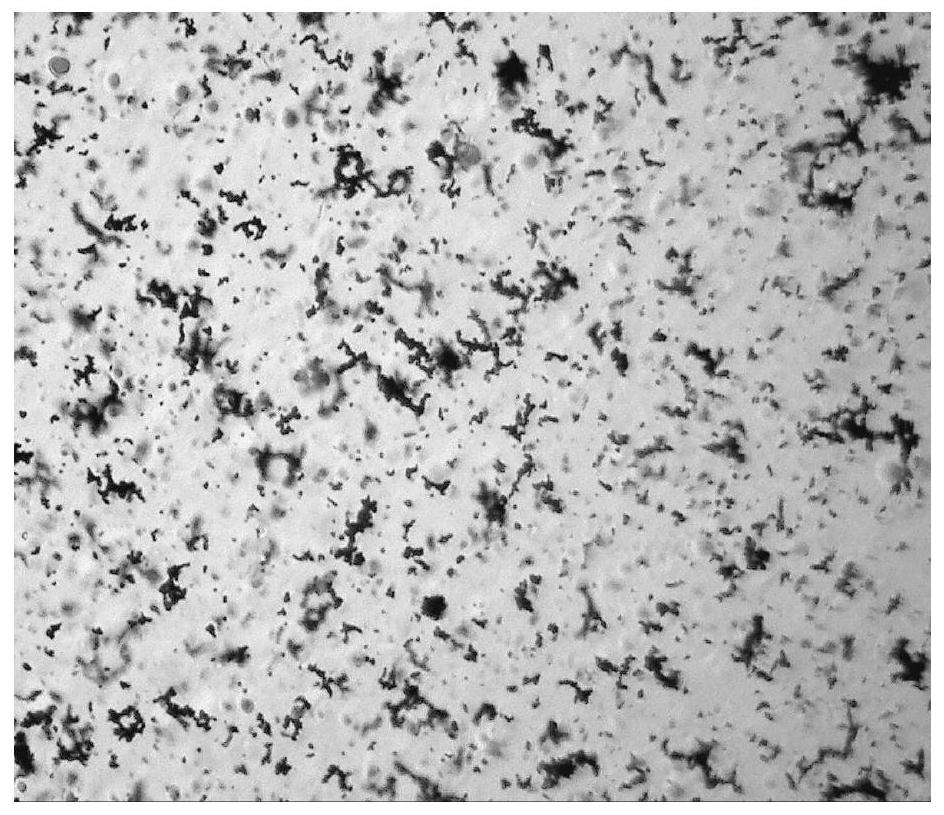

[0039] Weigh the required conductive particles, the specific conductive particles are nickel powder, the particle diameter is 10±5μm, add to the mixture A in batches, continue to stir until uniform to obtain the mixture B;

[0040] Slowly add mixture B to the remaining 95% glue and continue to stir until the conductive glue is evenly formed. The conductive glue can form the final conductive glue after adding other required components, and then it can be coated on the machine for production.

Embodiment 2

[0042] Weigh 5% of the total weight of acrylic glue BB-01 required for this production, add it to toluene and disperse it with a mixer until it is uniform to obtain a mixture A;

[0043] Weigh the required conductive particles, the specific conductive particles are nickel powder, the particle diameter is 40±5μm, add to the mixture A in batches, continue to stir until uniform to obtain the mixture B;

[0044] Slowly add mixture B to the remaining 95% glue and continue to stir until the conductive glue is evenly formed. The conductive glue can form the final conductive glue after adding other required components, and then it can be coated on the machine for production.

Embodiment 3

[0046] Weigh 15% of the total weight of the acrylic glue BB-02 required for this production, add it to toluene and disperse it with a mixer until it is uniform to obtain a mixture A;

[0047] Weigh the required conductive particles, the specific conductive particles are nickel powder, the particle diameter is 10±5μm, add to the mixture A in batches, continue to stir until uniform to obtain the mixture B;

[0048]Slowly add mixture B to the remaining 85% glue and continue to stir until the conductive glue is evenly formed. The conductive glue can form the final conductive glue after adding other required components, and then it can be coated on the machine for production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com