Mesoporous-microporous composite Y molecular sieve with through hole structure and preparation method thereof

A molecular sieve and through-hole technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of the proportion of mesopores to be further improved, the introduction of sieve heteroatoms is low, and the improvement can be achieved. and utilization rate, high introduction amount, and the effect of reducing diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

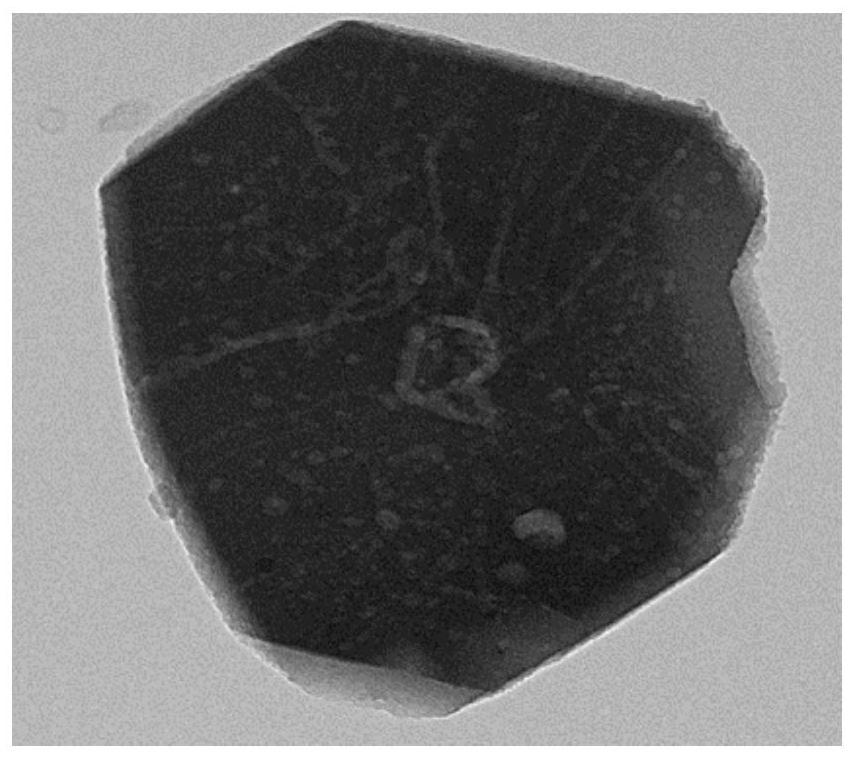

Image

Examples

Embodiment 1

[0036] 1) In the first step, place the boron-containing Beta molecular sieve (i.e. B-Beta molecular sieve) in a muffle furnace at 550° C. for 6 h to remove the template agent, and weigh 5 g of the boron-containing Beta molecular sieve (B-Beta molecular sieve) to remove the template agent. 2 o 3 Content 2wt%, SiO 2 content 93.6wt%) was dissolved in 50ml of concentrated NaOH (3mol / L) solution, heated to boiling, stirred for 30min until the molecular sieves were completely dissolved and set aside.

[0037] 2) In the second step, 1.79g of sodium metaaluminate (Al 2 o 3 The content is 41wt%, Na 2 O content is 28.7%) is dissolved in 25.19g deionized water, adds 6.13g sodium hydroxide (purity 96%) under mechanical stirring, continues stirring, makes it dissolve completely, obtains high alkalinity sodium metaaluminate solution. In a stirring state, the above-mentioned high alkalinity sodium metaaluminate solution was added to 24.7g water glass (SiO 2 The content is 26.2wt%, Na 2...

Embodiment 2

[0041] 1) In the first step, the boron-containing Beta molecular sieve is placed in a muffle furnace at 580° C. for 5 h to remove the template agent, and 5 g of the boron-containing Beta molecular sieve (B 2 o 3 content of 2.3wt%, SiO2 content of 96.0wt%) was dissolved in 50ml of concentrated NaOH (3mol / L) solution, heated to boiling, stirred for 30min until the molecular sieves were completely dissolved and set aside.

[0042] 2) In the second step, 1.79g of sodium metaaluminate (Al 2 o 3 The content is 41wt%, Na 2 O content is 28.7%) is dissolved in 25.19g deionized water, adds 6.13g sodium hydroxide (purity 96%) under mechanical stirring, continues stirring, makes it dissolve completely, obtains high alkalinity sodium metaaluminate solution. In a stirring state, the above-mentioned high alkalinity sodium metaaluminate solution was added to 24.7g water glass (SiO 2 The content is 26.2wt%, Na 2 O content is 8.3%), after mixing evenly, continue to stir for 2 hours, and th...

Embodiment 3

[0046] 1) In the first step, the boron-containing Beta molecular sieve is placed in a muffle furnace at 600° C. for 4 h to remove the template agent, and 5 g of the boron-containing Beta molecular sieve (B 2 o 3 Content 2.5wt%, SiO 2 content 96.7wt%) was dissolved in 50ml of concentrated NaOH (3mol / L) solution, heated to boiling, stirred for 30min until the molecular sieves were completely dissolved and set aside.

[0047] 2) In the second step, 1.79g of sodium metaaluminate (Al 2 o 3 The content is 41wt%, Na 2 O content is 28.7%) is dissolved in 25.19g deionized water, adds 6.13g sodium hydroxide (purity 96%) under mechanical stirring, continues stirring, makes it dissolve completely, obtains high alkalinity sodium metaaluminate solution. In a stirring state, the above-mentioned high alkalinity sodium metaaluminate solution was added to 24.7g water glass (SiO 2 The content is 26.2wt%, Na 2 O content is 8.3%), after mixing evenly, continue to stir for 2 hours, and then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com