Double-station full-automatic plasma feeding and discharging device

A fully automatic, two-station technology, applied in the direction of transportation and packaging, conveyor objects, object stacking, etc., to achieve the effect of ensuring work continuity, improving cleaning efficiency, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention. It should be noted that the related terms such as "first", "second", etc. can be used to describe various components, but these terms do not limit the assembly. These terms are only used to distinguish between one component and another component. For example, the first component can be referred to as a second component without departing from the scope of the invention, and the second component can also be referred to as the first component. The term "and / or" refers to any one or more of the related items and the description items.

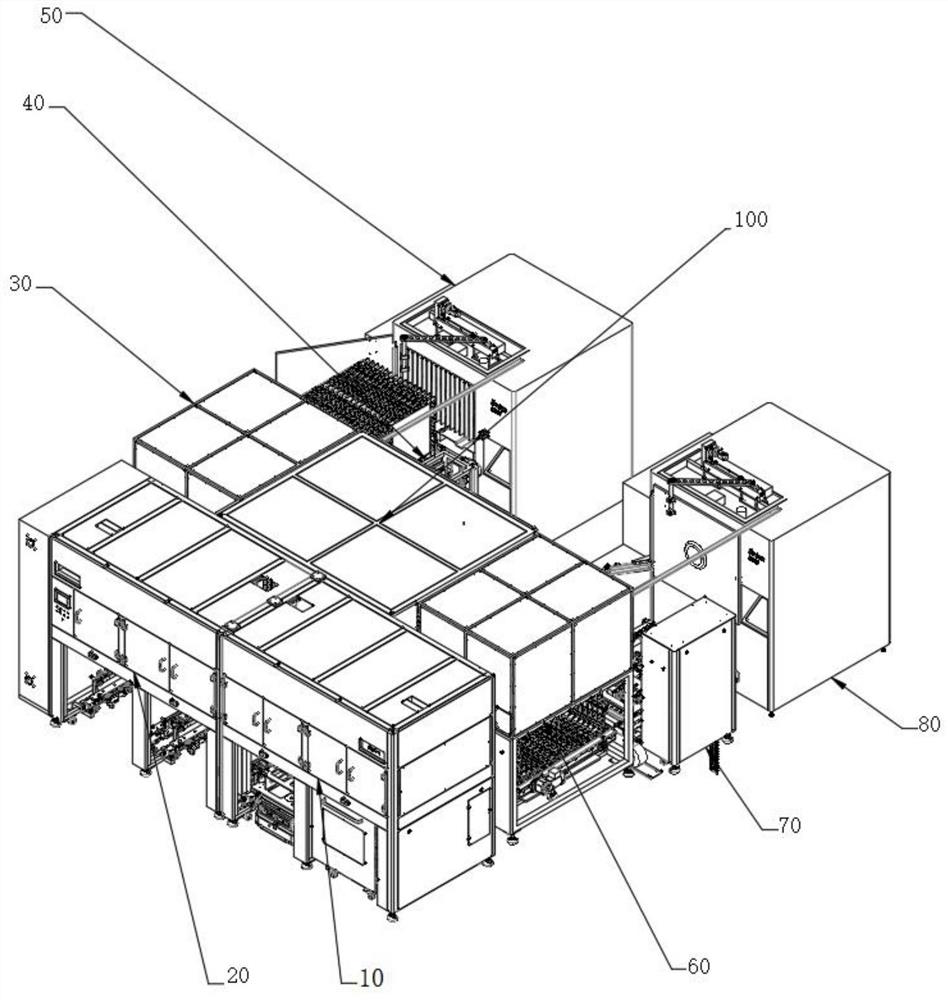

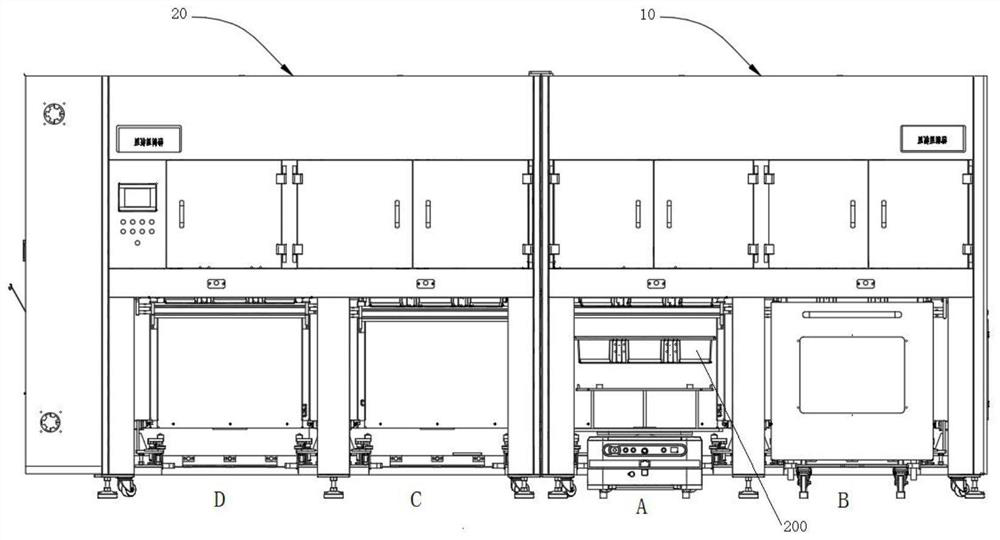

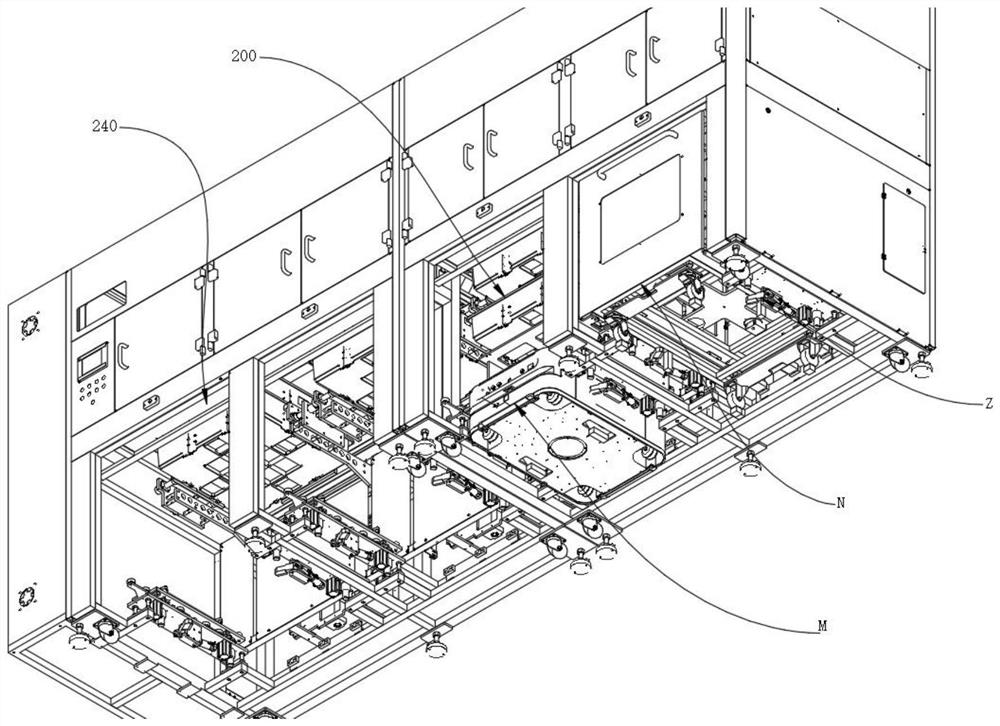

[0054]Such asfigure 1 Distancefigure 1 A three-dimensional schematic view of the two-station full-automatic plasma upper orifice for the present invention; a two-station fully automatic plasma upper and lower material, including the upper body 10, 1 corner mechanism 30, 2 corner mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com