Lifting type mobile contact net supporting device, mobile contact net and operation method

A technology of supporting devices and catenary, applied in the direction of overhead lines, etc., can solve problems such as safety hazards, and achieve the effects of reliable mechanism, low failure rate, and increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

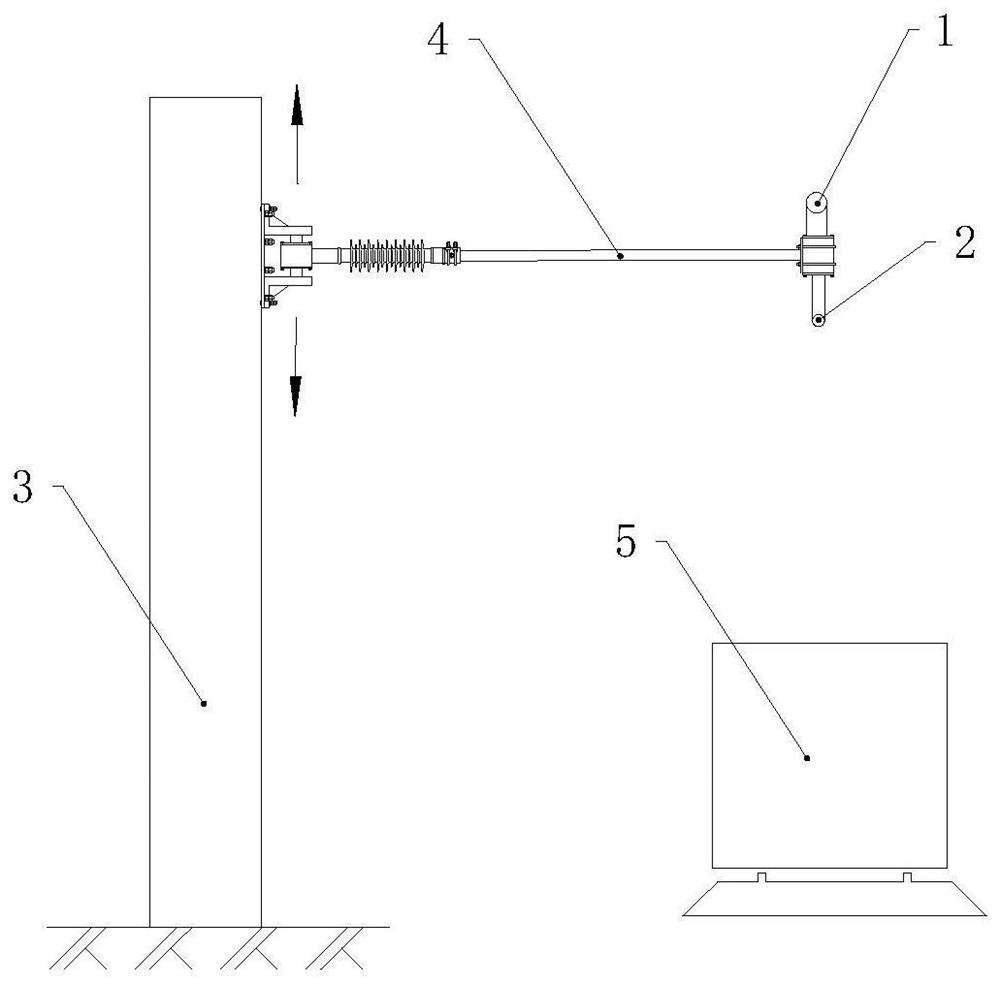

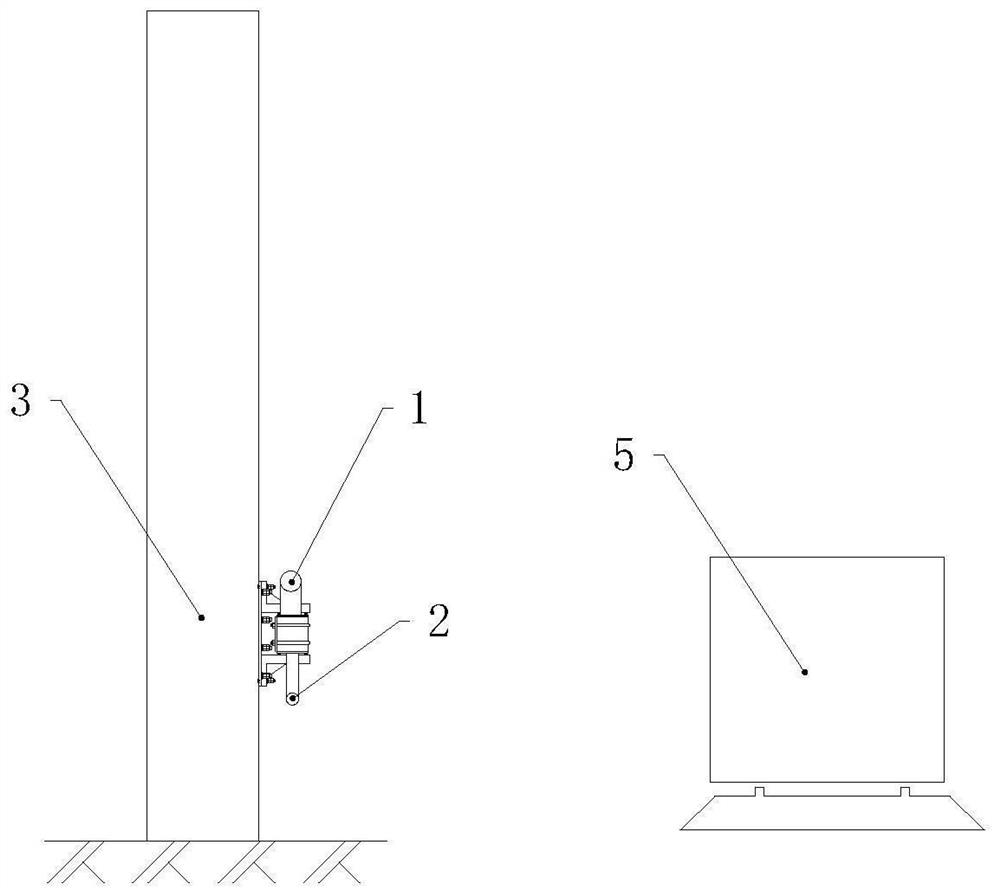

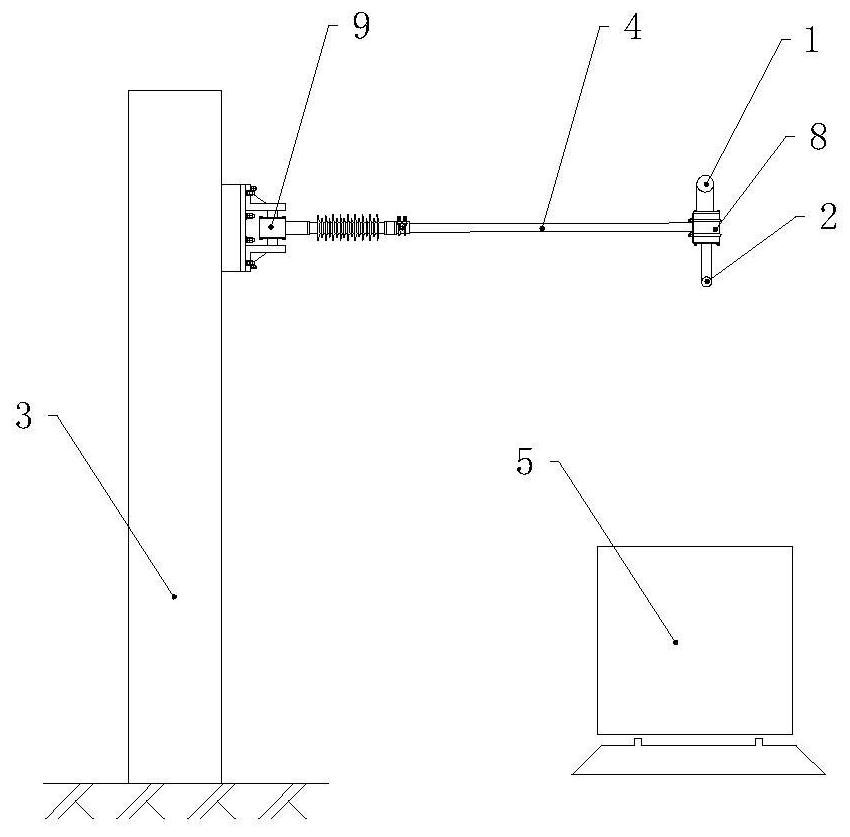

[0130] Another embodiment of the present invention: the support mechanism adopts a retractable support mechanism, and the retractable support mechanism stretches out to drive the bearing cable 1 and / or the contact line 2 to move from the non-working position to the working position; or The retractable support mechanism described above drives the catenary cable 1 and / or the contact line 2 to move from the working position to the non-working position. Such as Figure 6A to Figure 6C As shown, adopt described supporting mechanism to stretch out or withdraw in the mode of scissors row. Such as Figure 7A to Figure 7C As shown, stretching out is realized by adopting a telescopic step-by-step stretching method.

[0131] Such as Figure 7D As shown, a horizontal slideway 25 is set on the column, and a driving mechanism, such as an electric drive, is used to drive the support mechanism 4 to stretch out from the horizontal slideway to the working position; Horizontal slideway 25 so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com