Technique for producing small-size complex inner cavity titanium alloy casting by utilizing metal core

A technology of metal cores and process methods, applied in metal material coating process, metal processing equipment, cores, etc., can solve the problems that slurry coating and drying cannot be realized, and achieve high thermal shock resistance and high thermal stability Slight effects of sexual, physical and chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

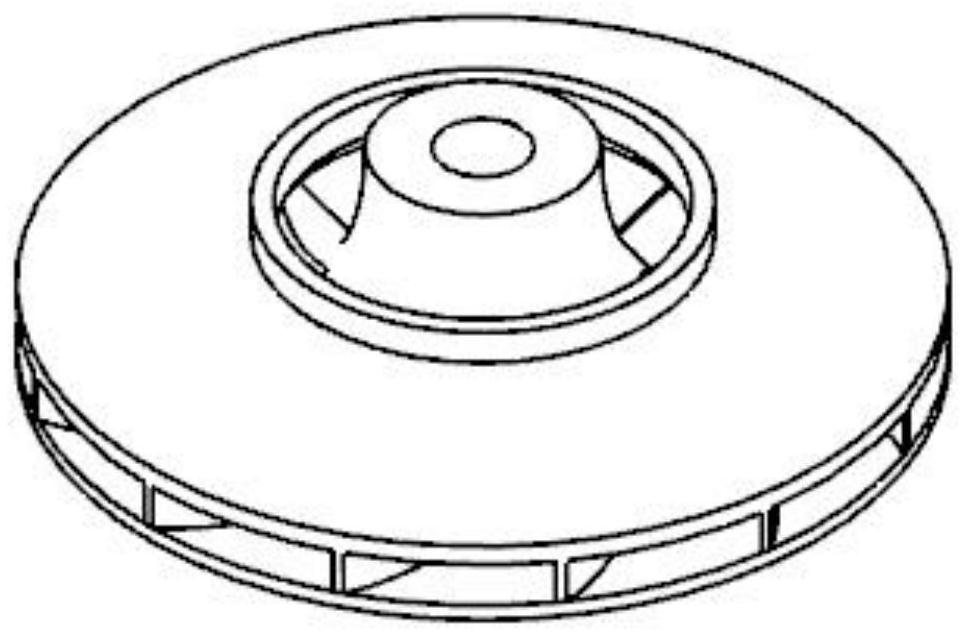

[0032] Embodiment 1 (see figure 1 with figure 2 ): In the present embodiment, a process for utilizing a metal core to produce a closed impeller with an opening between the loam cake and the lower cover less than 5mm is carried out in the following steps:

[0033] 1. Use iron-based alloy to make the core, and then use vacuum plasma spraying equipment to spray Y on the surface of the core. 2 o 3 Coating, the thickness of the coating is 0.15mm, and after drying at 20°C for 24 hours, a coated core is obtained; the iron-based alloy is Q235 steel;

[0034] Two, the core is placed in the aluminum alloy wax mold, and the wax mold is pressed to obtain the wax mold; the material of the wax mold is aluminum alloy;

[0035] 3. Slurry the surface layer and the back layer of the wax model cleaned on the surface. Both the surface layer slurry and the back layer slurry are prepared from refractory materials and binders. The refractory material of the surface layer slurry is 85%. Y 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com