Method for preparing water glass by utilizing purified iron tailings

A technology of iron tailings and water glass, which is applied in the direction of solid separation, etc., can solve the problems of waste of resources, environment and pollution, and achieve the effects of avoiding environmental pollution, simple process, harmless disposal and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

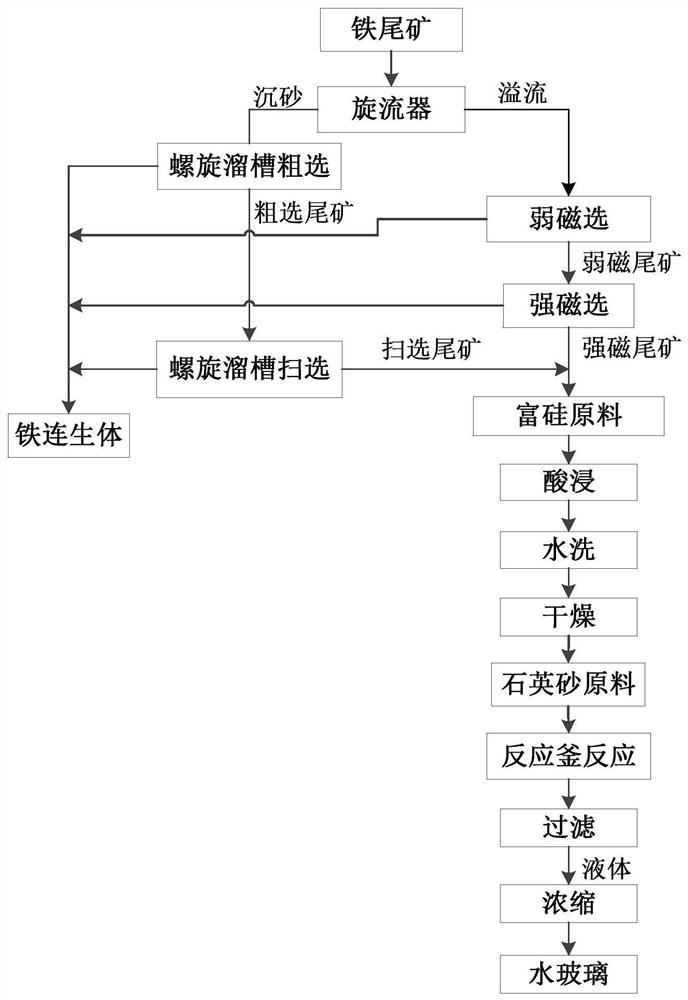

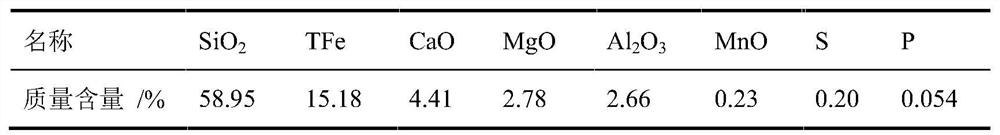

[0038] The iron tailings are subjected to cyclone classification treatment to obtain grit and overflow products. Grit products are fed into a Φ1.5m spiral chute for roughing, rougher tailings are fed into a Φ1.5m spiral chute for sweeping; overflow products are sent to a drum magnetic separator with an entry field strength of 150mT for weak magnetic separation, The weak magnetic tailings are subjected to strong magnetic separation by a drum magnetic separator with an entry field strength of 1000mT; the scavenging tailings and strong magnetic tailings are combined into silicon-rich raw materials. At this time, SiO in the silicon-rich raw materials 2 The mass percentage composition is 86.68%. The silicon-rich raw material is pickled with a mass concentration of 10% to remove acid-soluble impurities such as Ca, Mg, Al and Fe in the silicon-rich raw material, and then washed with water (the washing liquid is fed into the recovery treatment system), and dried to obtain Prepare raw...

Embodiment 2

[0041] The iron tailings are subjected to cyclone classification treatment to obtain grit and overflow products. The grit products are fed into the Φ1.2m spiral chute for roughing, and the rougher tailings are fed into the Φ1.2m spiral chute for sweeping; the overflow products are sent to the drum magnetic separator with an entry field strength of 140mT for weak magnetic separation. The weak magnetic tailings are sent to the drum magnetic separator with an entry field strength of 800mT for strong magnetic separation; the scavenging tailings and strong magnetic tailings are combined into silicon-rich raw materials. At this time, SiO in the silicon-rich raw materials 2 The mass percent composition is 83.47%. The silicon-rich raw material is pickled with a mass concentration of 15% to remove acid-soluble impurities such as Ca, Mg, Al and Fe in the silicon-rich raw material, then washed with water (the washing liquid is fed into the recovery treatment system), and dried to obtain ...

Embodiment 3

[0044] The iron tailings are subjected to cyclone classification treatment to obtain grit and overflow products. The grit products are fed into the Φ1.5m spiral chute for roughing, and the rougher tailings are fed into the Φ1.5m spiral chute for sweeping; the overflow products are sent to the drum magnetic separator with an entry field strength of 140mT for weak magnetic separation. The weak magnetic tailings are sent to the drum magnetic separator with an entry field strength of 850mT for strong magnetic separation; the scavenging tailings and strong magnetic tailings are combined into silicon-rich raw materials. At this time, SiO in the silicon-rich raw materials 2 The mass percent composition is 84.52%. Pickling the silicon-rich raw material with an acid mass concentration of 10% to remove acid-soluble impurities such as Ca, Mg, Al and Fe in the silicon-rich raw material, then washing with water (the washing liquid is fed into the recovery treatment system), and drying to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com