Personnel disinfection channel applied to cold chain logistics

A cold chain logistics and channel technology, applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve problems such as poor disinfection effect, inability to collect disinfected water, and inability to disinfect, and achieve better disinfection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

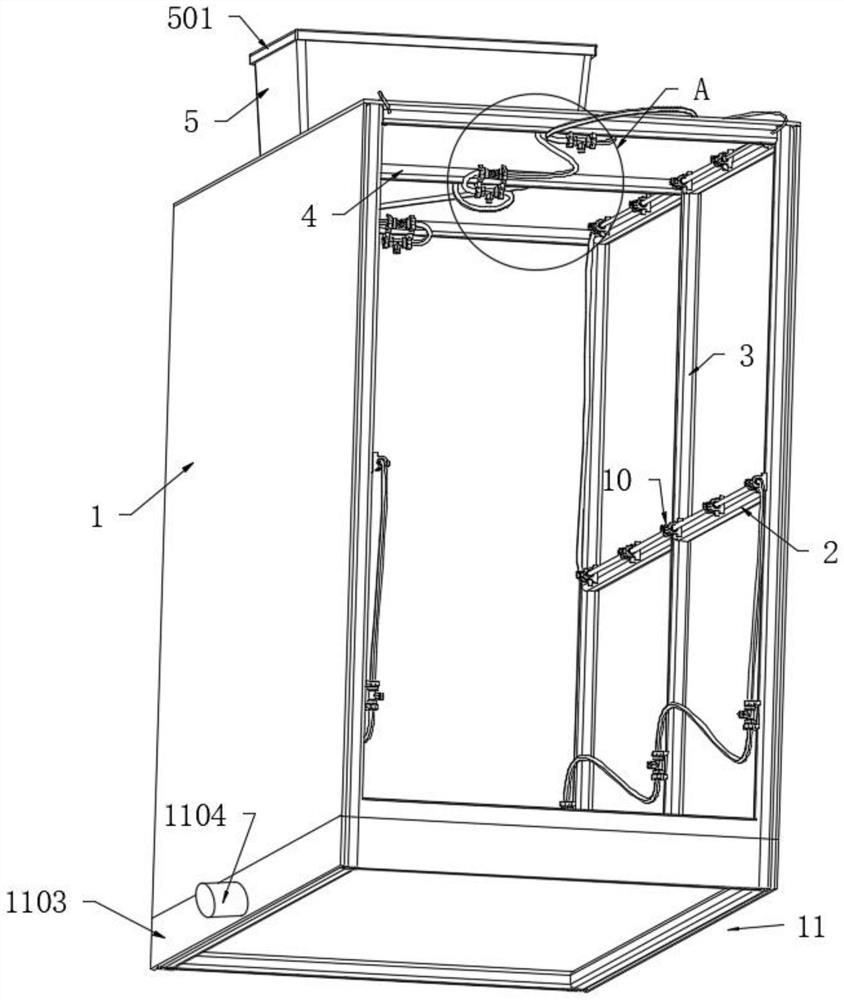

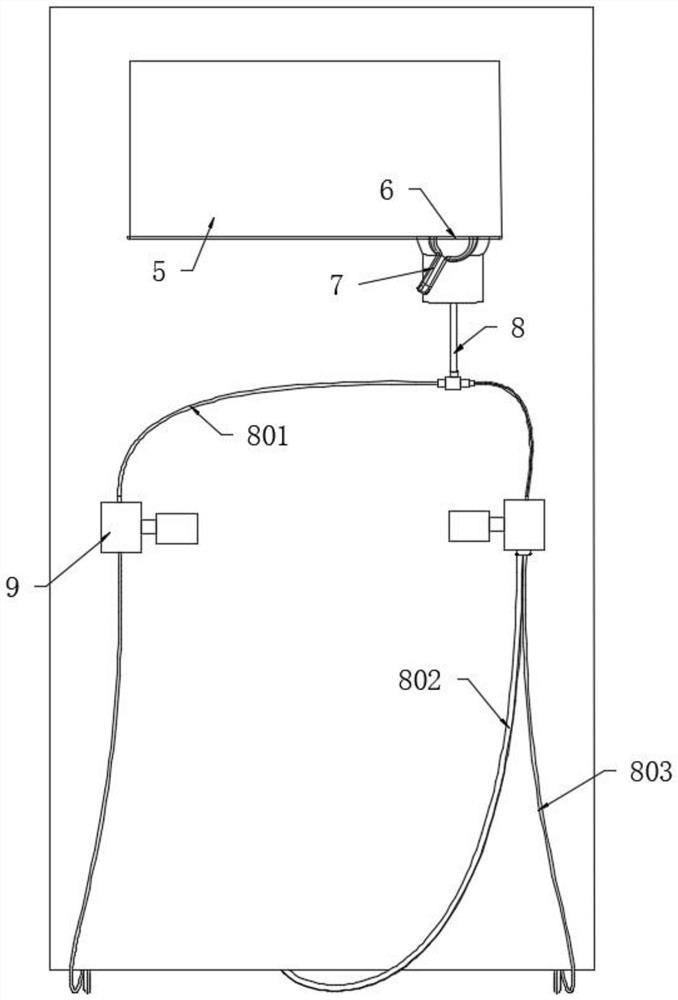

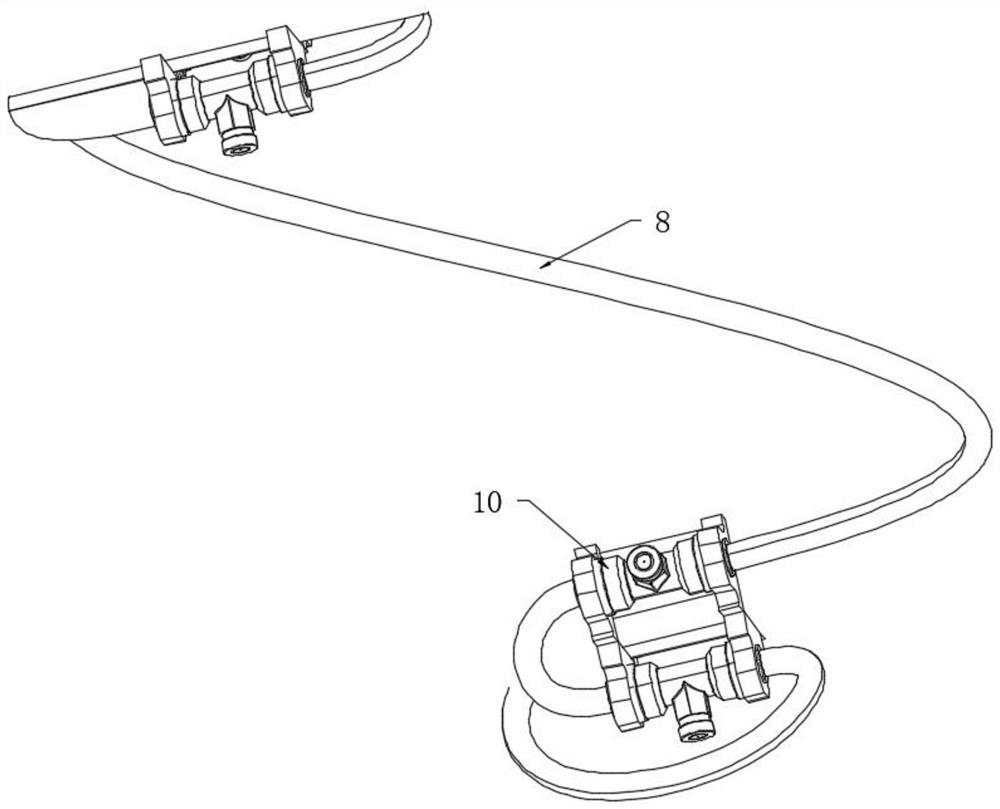

[0030] like Figure 1-4 As shown, a personnel disinfection channel applied to cold chain logistics includes a channel body 1, and a plurality of uniformly distributed horizontal struts 2 and longitudinal struts 3 are arranged on both sides of the channel body 1, and the interior of the channel body 1 A plurality of ejector rods 4 evenly distributed are arranged on the top, and the top of the channel body 1 is fixedly connected with a disinfection box 5 by bolts. One side of the disinfection box 5 is provided with a water outlet 6, and a water valve switch 7 is arranged on the water outlet 6. The valve switch 7 is connected with a disinfection water pipe 8, and the disinfection water pipe 8 is provided with multiple groups of correspondingly distributed micro-water pumps 9. The micro-water pumps 9 and the passage body 1 are fixedly connected by bolts, and the horizontal strut 2, the longitudinal strut 3 and the top A plurality of evenly distributed nozzles 10 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com