Shoelace winding machine

A technology of winding machine and winding mechanism, which is applied in the direction of shoemaking machinery, footwear, shoe binding objects, etc., can solve the problems of difficult to maintain stable appearance quality and high labor cost, and achieve labor cost saving, stable winding quality, avoid The effect of artificial differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

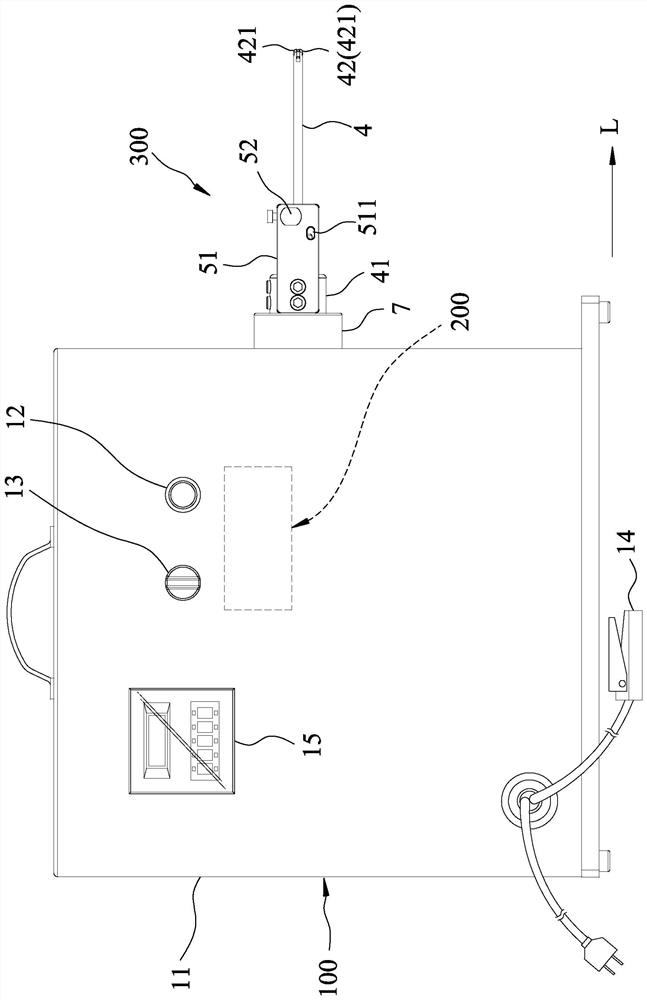

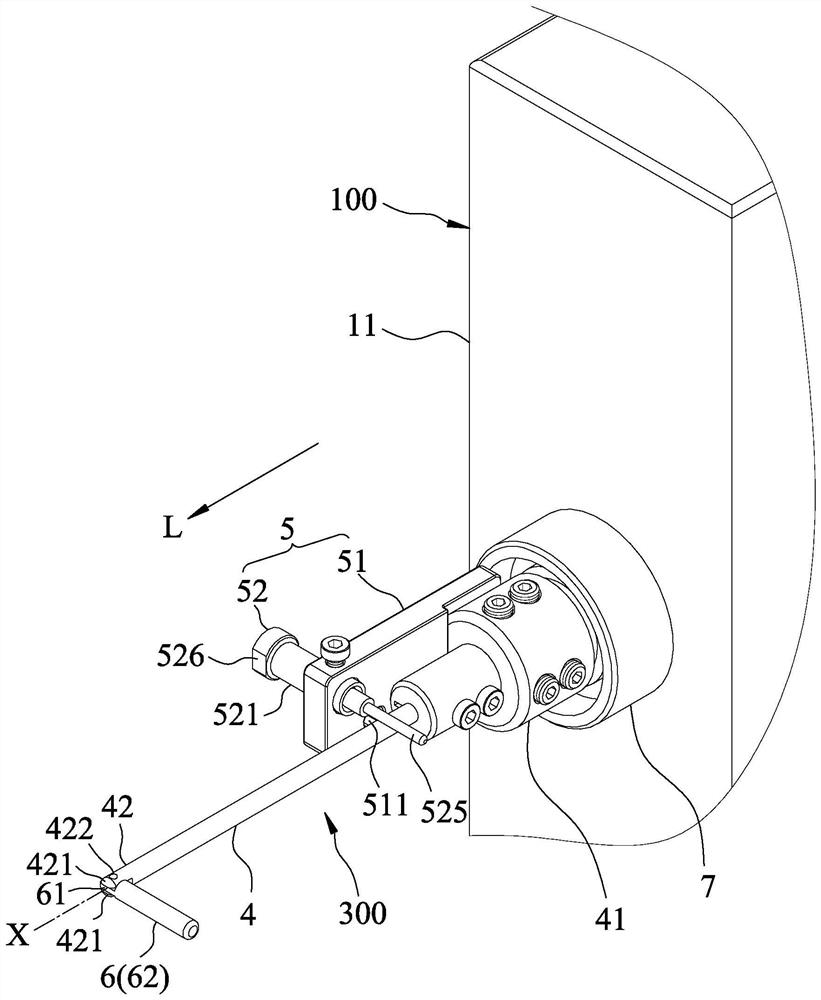

[0023] refer to figure 1 , figure 2 and Figure 8 , an embodiment of the shoelace winding machine of the present invention is suitable for winding a shoelace 9 into a predetermined shape 9', the shoelace 9 has two opposite ends 91 and a lace connected to the end 91 The flexible section 92, the predetermined shape 9' is a helically wound shape. The shoelace winding machine includes a base unit 100 , a control unit 200 , and a winding mechanism 300 .

[0024] The base unit 100 includes a casing 11 and a switch 12 . The switch 12 is arranged on the casing 11, and the switch 12 is used for turning on and off the machine. The control unit 200 is disposed in the inner space of the housing 11 and is electrically connected to the switch 12 .

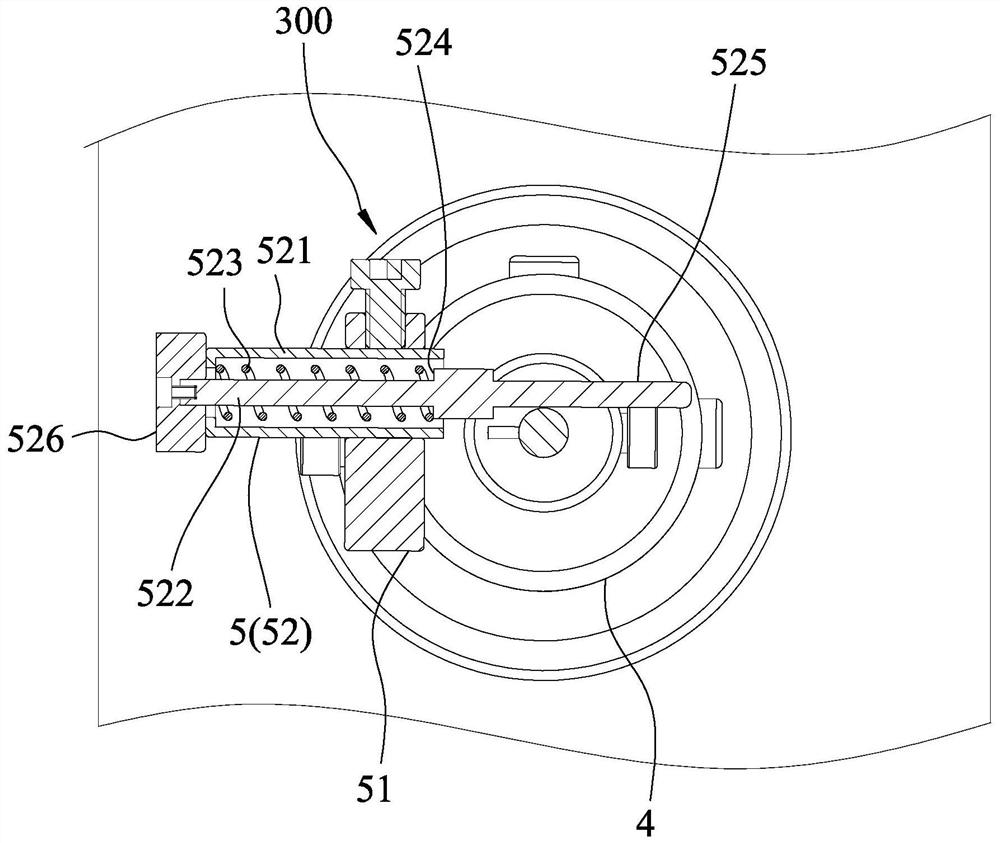

[0025] The winding mechanism 300 is rotatably arranged on the casing 11 of the base unit 100 and extends outward from the casing 11. The winding mechanism 300 includes a central shaft 4, a front support arm unit 5, A rear support arm 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com