Medium-high voltage oil-resistant rubber shielding cable

A technology of oil-resistant rubber and shielded cables, which is applied in the direction of power cables, insulated cables, cables, etc. with shielding layer/conductive layer. performance, reducing mutual electromagnetic interference, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

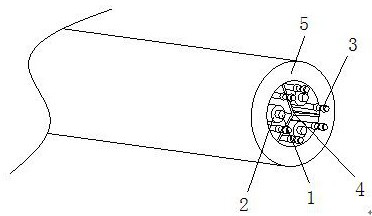

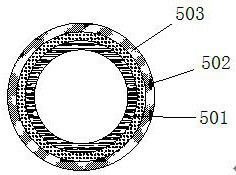

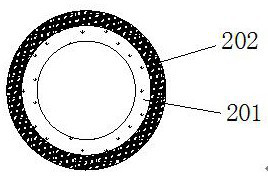

[0025] see Figure 1-3 , the present invention provides the following technical solutions: a medium and high voltage oil-resistant rubber shielded cable, including a conductor 1, an inner skin 2, a filler 3, a Y-shaped isolation strip 4 and an outer skin 5, and the inner skin 2 is fixedly connected to the outside of the conductor 1, The inner skin 2 includes two layers, namely the inner shielding layer 201 and the insulating layer 202. The inner shielding layer 201 is wrapped on the outside of the conductor 1, and the insulating layer 202 is wrapped on the outside of the inner shielding layer 201. The number of conductors 1 is three, Y-shaped The isolation strip 4 separates the conductor 1, the outer skin 5 is wrapped on the outside of the Y-shaped isolation band 4, and the filler 3 is arranged in the gap between the outer skin 5 and the Y-shaped isolation band 4. The outer skin 5 includes three layers, respectively It is an outer shielding layer 501, a sheath layer 502 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com