High-strength escape pipe convenient to socket and fix

A high-strength, escape pipe technology, applied to high-strength escape pipes. , In the field of escape pipelines, it can solve problems such as poor compression resistance, poor socket stability, and heavy weight of tunnel escape pipelines, achieving strong traction strength, improving strength, and solving the overall hoisting problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

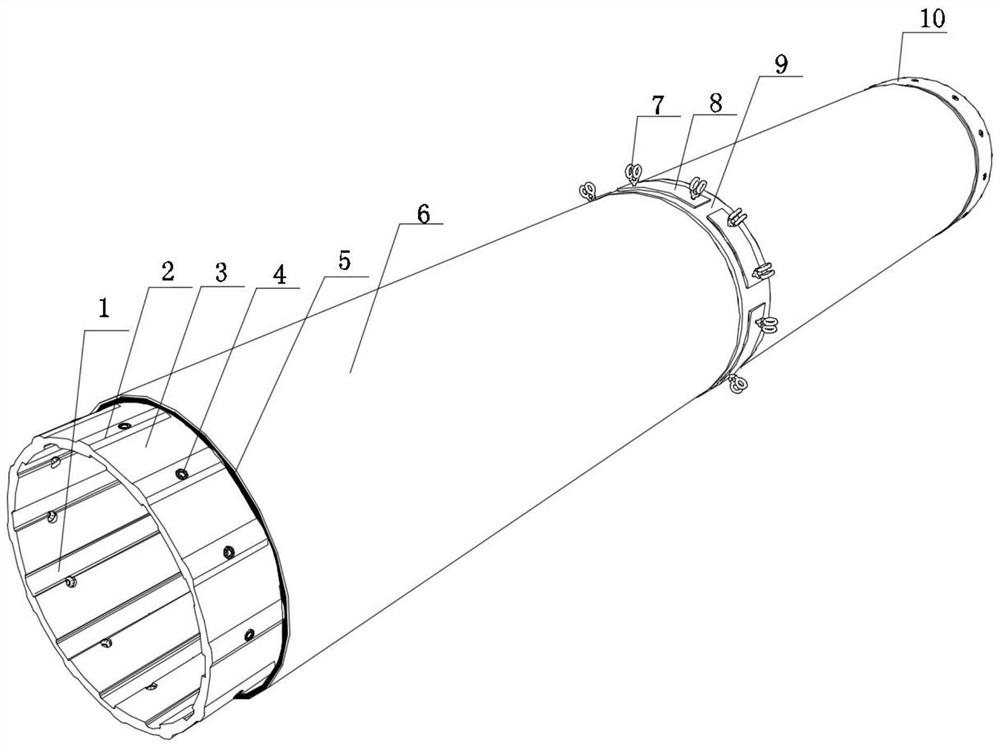

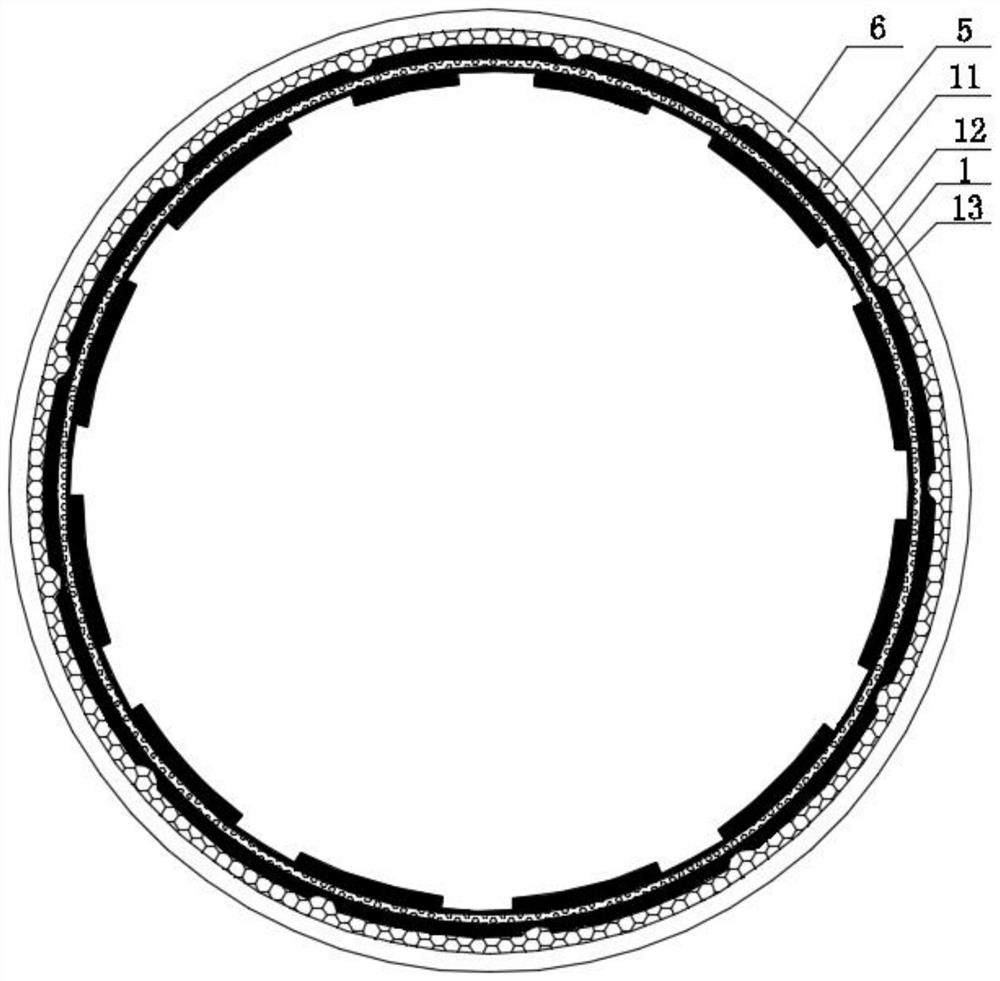

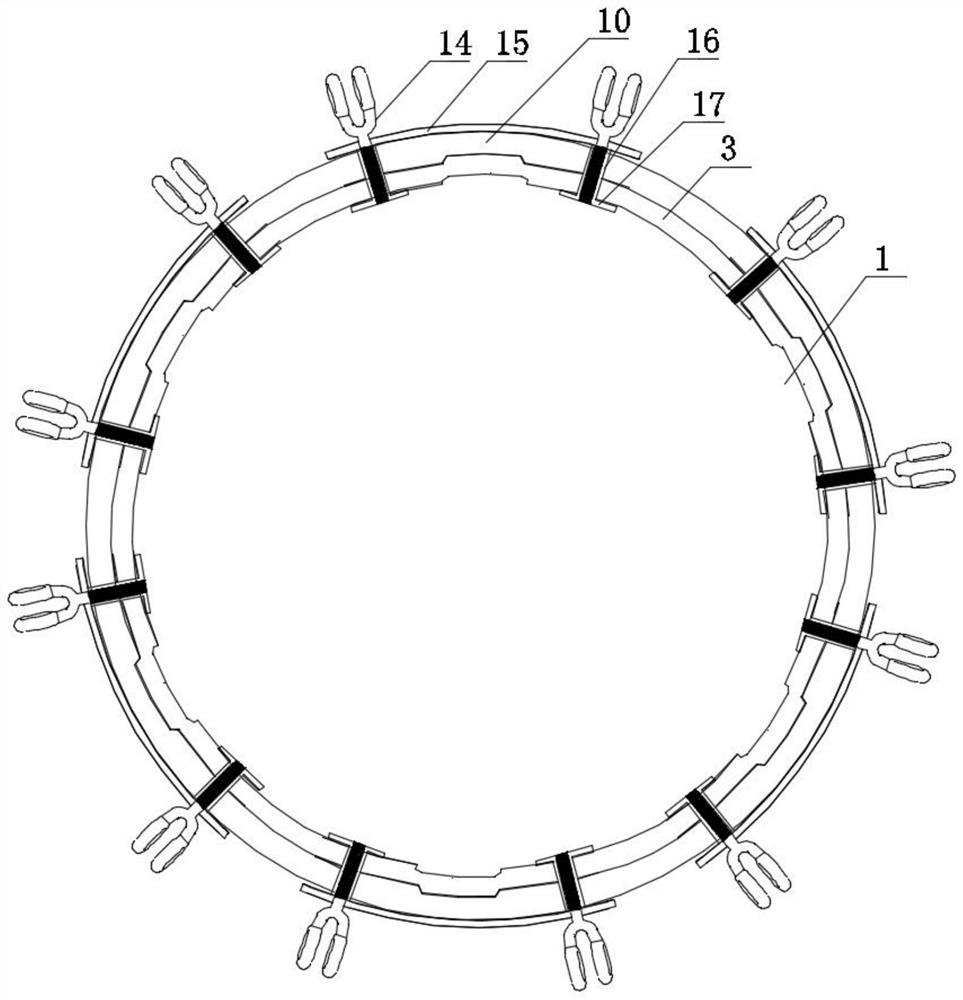

[0027] A high-strength escape pipe that is conveniently socketed and fixed, including several unit pipe bodies connected end to end, the unit pipe body includes an inner pipe body and an outer pipe body 6, and the inner pipe body includes a pipe body section 11, a socket head Section 10 and plug section 3, one end of the pipe body section is extended to form a socket section, and the other end is extended to form a plug section; the pipe wall of the pipe body section is a hollow structure, and the hollow structure of the pipe wall is filled with foam Form buffer layer 12, described foam is made by mixing blowing agent A and blowing agent B, and outer pipe body is coaxially sheathed on described pipe b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com