Heavy self-turning electric rail flat car

A track and electric technology, applied in motor vehicles, electric locomotives, locomotives, etc., can solve the problems of high pressure on the turntable, high cost, and turntable failure, and achieve the effect of reducing the use of the turntable, expanding the use range, and ensuring no loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

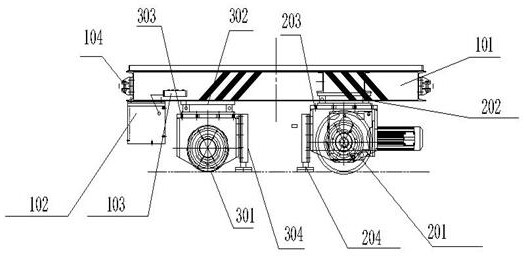

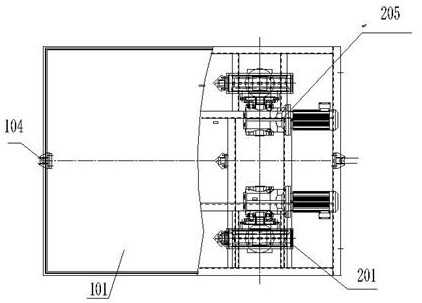

[0018] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0019] A heavy-duty self-turning electric rail flat car, the heavy-duty self-turning electric rail flat car includes: a frame 101, a load wheel set and a driving mechanism 205; the frame 101 is a rectangular frame made of welded steel, the A vehicle-mounted control box 102 is installed at the rear end of the frame, and a wireless signal receiving device is installed in the vehicle-mounted control box 102. The load wheel group is composed of four load steel wheels, and two of them are installed at the front end of the vehicle frame 101. The load wheel is a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com