Ink box capable of conveniently supplying ink

A technology for supplying ink and ink cartridges, which is applied to the field of ink cartridges that can supply ink conveniently, can solve the problems of easily soiling the surrounding environment of the hands, and it is difficult to ensure the ink output performance of the ink cartridges, so as to avoid the entry of sundries and ensure the effect of normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

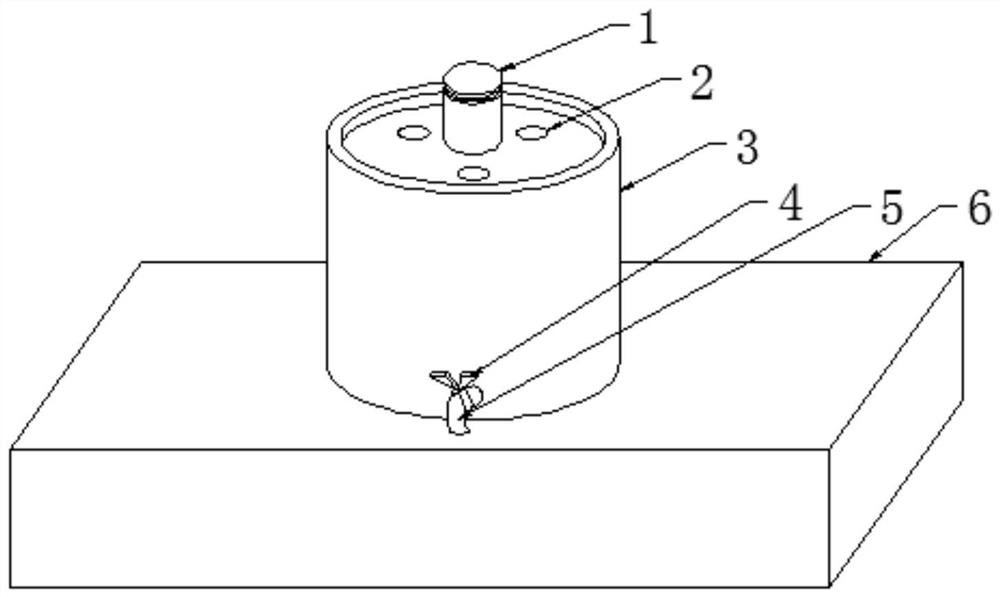

[0020] Embodiment 1 is basically as attached figure 1 Shown: a kind of ink box that can conveniently supply ink, comprises box body 6, ink supply box 3 and piercing needle, ink and sponge are arranged in box body 6, and the bottom of box body 6 is provided with ink outlet hole.

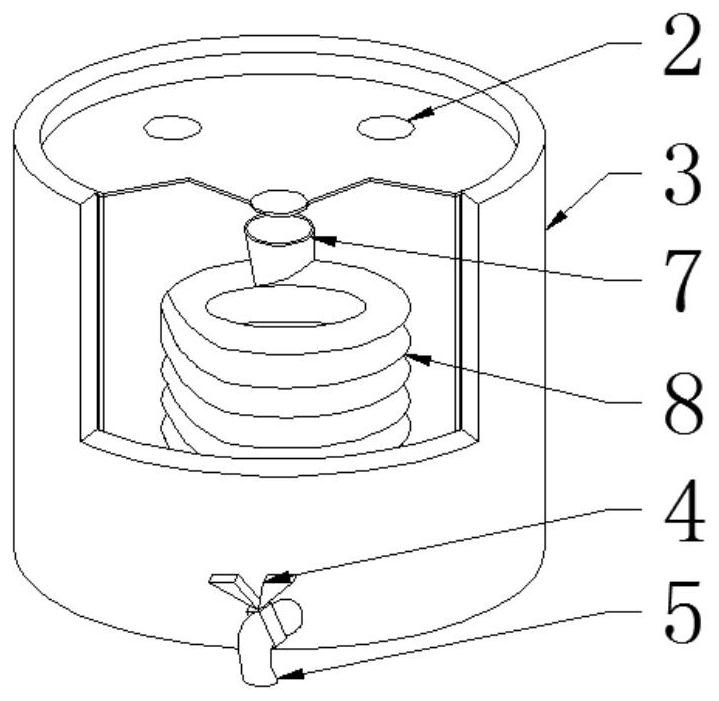

[0021] The ink cartridge 3 is arranged on the top of the box body 6, combined with figure 2 As shown, the ink supply cartridge 3 is a hollow cylindrical structure, and the interior of the ink supply cartridge 3 is connected with three partitions, and the partitions divide the interior of the ink supply cartridge 3 into three ink supply chambers. The wall of each ink supply chamber is provided with an ink injection hole, and the ink injection hole is sealed and connected with a silica gel sheet 2. A first guide tube 5 is connected between the lower end of the ink supply chamber and the box body 6, and the first guide The pipe 5 is provided with a stop valve 4, and the inside of the ink supply chamber...

Embodiment 2

[0023] Embodiment 2, the difference from Embodiment 1 is: the ink supply cartridge 3 is a hollow cylindrical structure, and the inside of the ink supply cartridge 3 is connected with a cross partition, and the partition divides the interior of the ink supply cartridge 3 into four ink supply chambers .

Embodiment 3

[0024] The difference between Embodiment 3 and Embodiment 1 is that the nozzle 7 at the upper end of the second draft tube 8 is funnel-shaped.

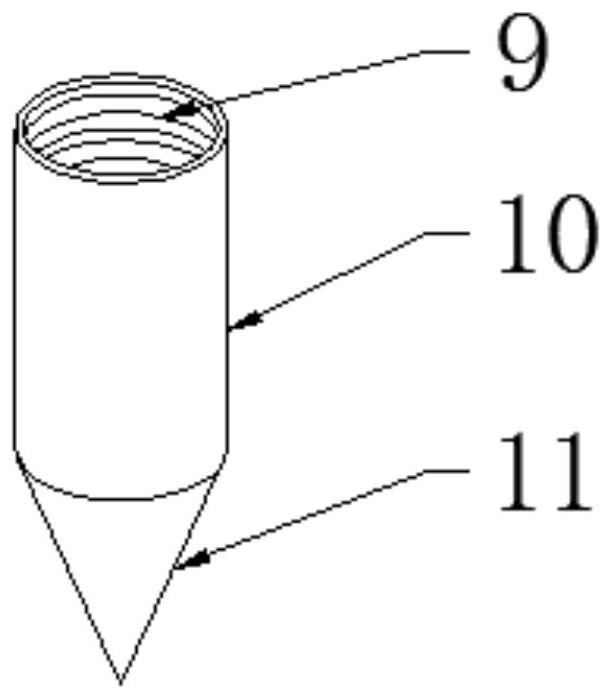

[0025] Taking Embodiment 1 as an example, the specific implementation process is as follows: before use, use a hose that can be tightly sleeved with the needle 10 of the piercing needle, and the hose is inserted into a container containing ink, and the needle point 11 of the piercing needle is Puncture the silicone sheet 2 on one of the ink supply chambers. Since the interior of the ink supply chamber is vacuum, the ink in the container will smoothly enter the second ink supply chamber along the hose under the action of internal and external negative pressure. In the guide tube 8, open the stop valve 4, the ink enters the box body 6 from the first guide tube 5, and finally pulls out the puncture needle, because the punctured silica gel sheet 2, the punctured silica gel fragment It is still connected to each other, and the silica gel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com