Full-automatic tire deburring machine

A deburring machine and fully automatic technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of affecting product quality, manual error tires, high mold maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are intended to illustrate the invention, but are not intended to limit the scope of the invention.

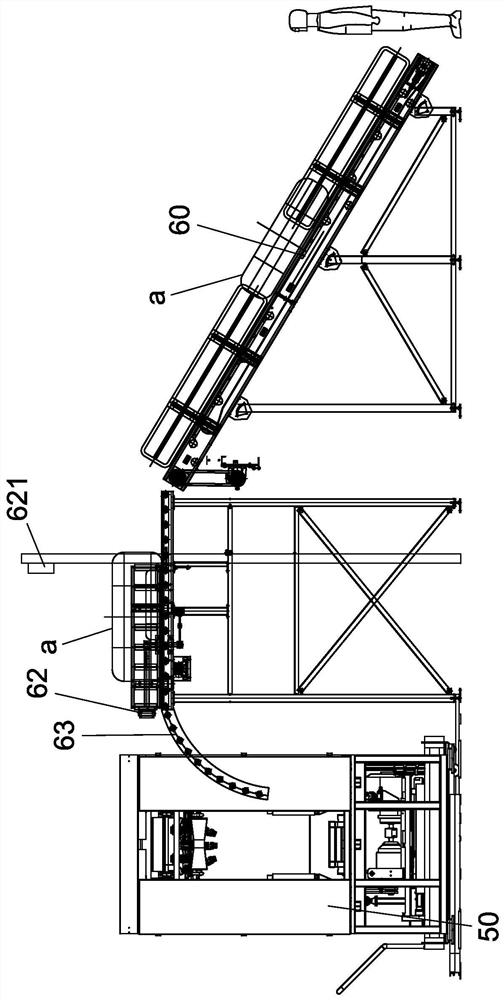

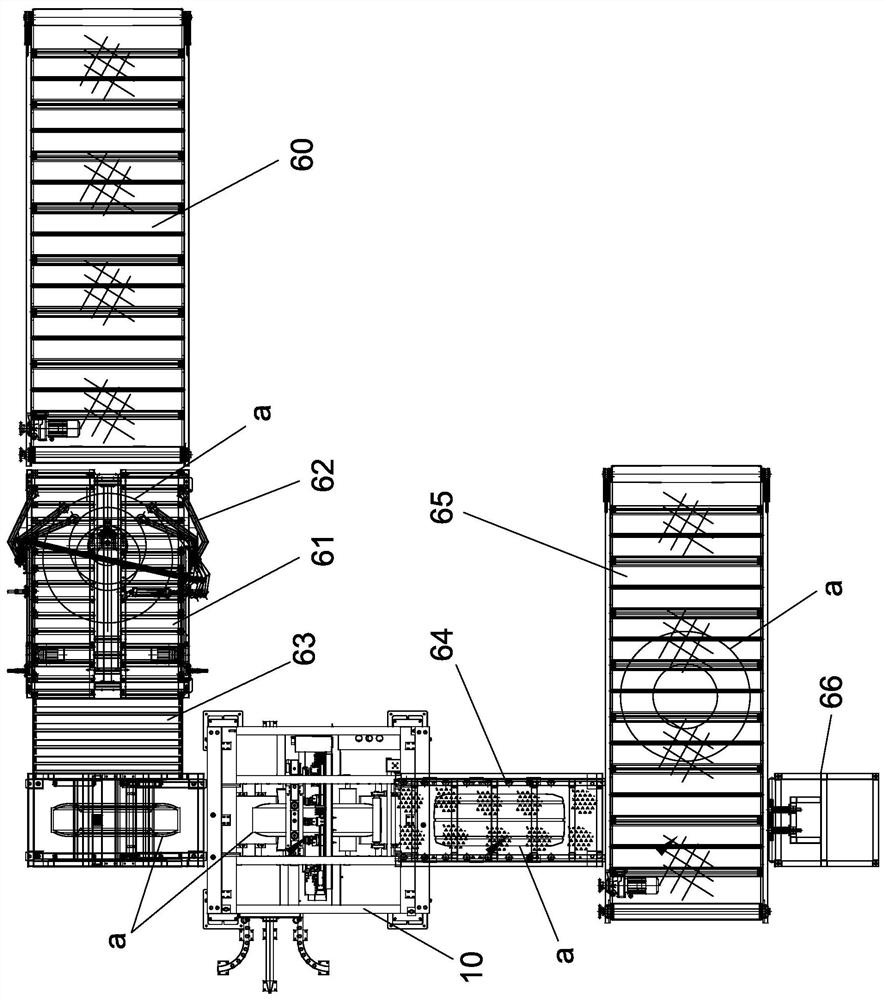

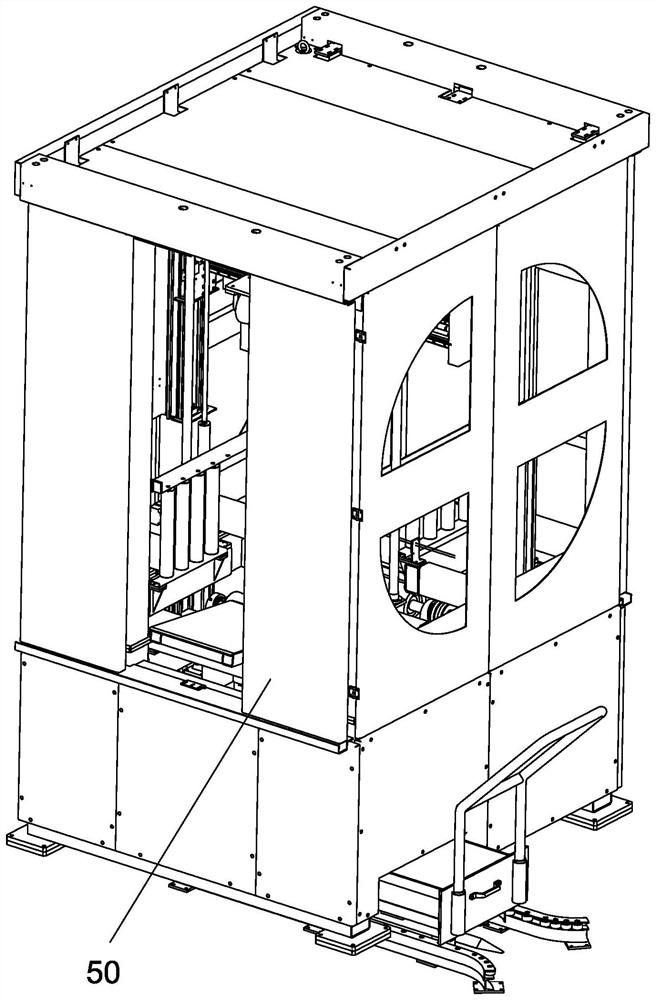

[0066]referenceFigure 1 to 11,Such asFigure 1 to 11A fully automatic tire decapitation machine, including a rack 10, and the frame 10 is provided in a tire pad 101, a lower middle roller 102, a drive roller 11, and a front plate along the tire A in-and-directional direction. 103. The rack 10 also includes a canned upper centering roller 12, which is located above the lower middle roller 102 and the active roller 11, and the rack 10 is also provided in the delivery The barrier roller 13 can be lifted above the plate 103, the active roller 11 driven by the drive motor 111, the downstream medium roller 102, the diameter of the medium in the upper middle roller 12 is less than that of both ends, the downstream roller 102, active The roller 11, the upper middle roller 12 and the barrier roller 13 are parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com