Multi-angle plastic mold surface milling device and plastic mold machining process

A plastic mold, multi-angle technology, applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of affecting the milling efficiency, increasing the workload of the staff, inconvenient use, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

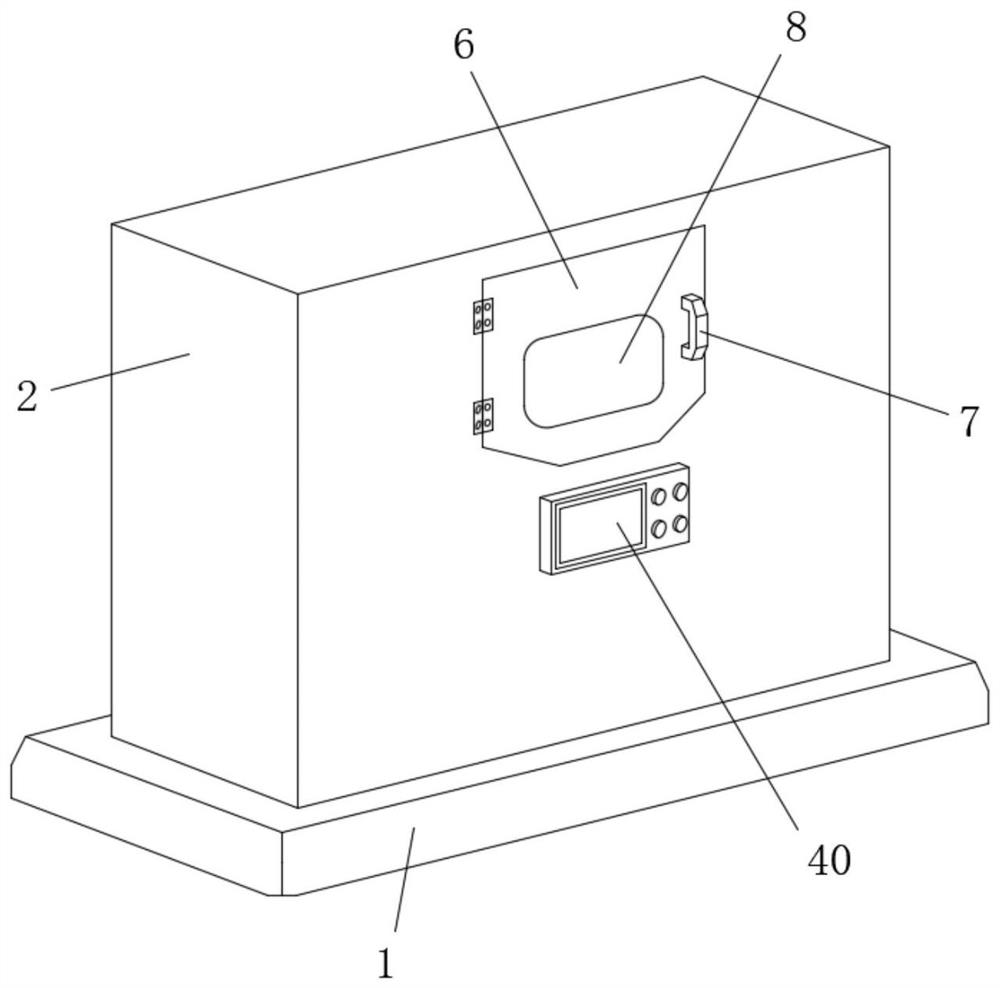

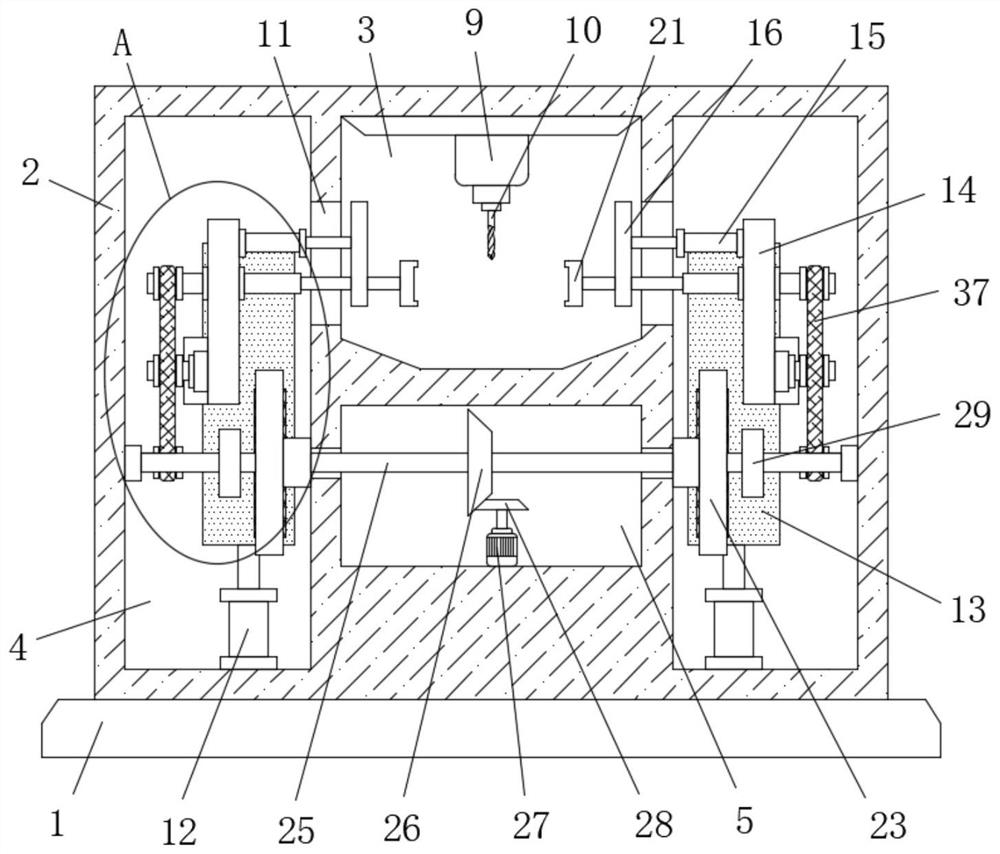

[0038] refer to Figure 1-10 , a multi-angle plastic mold surface milling device, including a base 1, the top of the base 1 is fixedly connected with a box 2, and the inside of the box 2 is respectively provided with a milling chamber 3, a driving chamber 5 and two transmission chambers chamber 4, the milling chamber 3 is located directly above the driving chamber 5, the two transmission chambers 4 are symmetrically located on both sides of the milling chamber 3, and the top inner wall of the milling chamber 3 is provided with a connecting seat 9, The bottom of the connecting seat 9 is provided with a milling cutter 10, and two moving holes 11 are symmetrically provided on the inner walls of both sides of the milling chamber 3, and the two moving holes 11 are connected with the two transmission chambers 4 respectively, and the two transmission chambers The inner wall of the bottom of the chamber 4 is fixedly connected with a lifting cylinder 12, and the vertically upward outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com