Open type heating and heat preservation hopper for reducing oxide inclusions and pouring method

A heating and heat preservation, open technology, applied in metal processing equipment, casting molding equipment, casting molds, etc., can solve the problems of unsatisfactory heat preservation effect of hoppers, oxidation and inclusion defects of castings, etc., and achieve good heat preservation effect , the effect of less oxidation inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] The invention provides an open tilting casting hopper which can be used for one-time pouring with a single mold or multiple molds. The main material of the bucket is cast iron, which is formed by sand casting. The hopper as a whole is installed on the tilting casting mold with inner hexagonal screws.

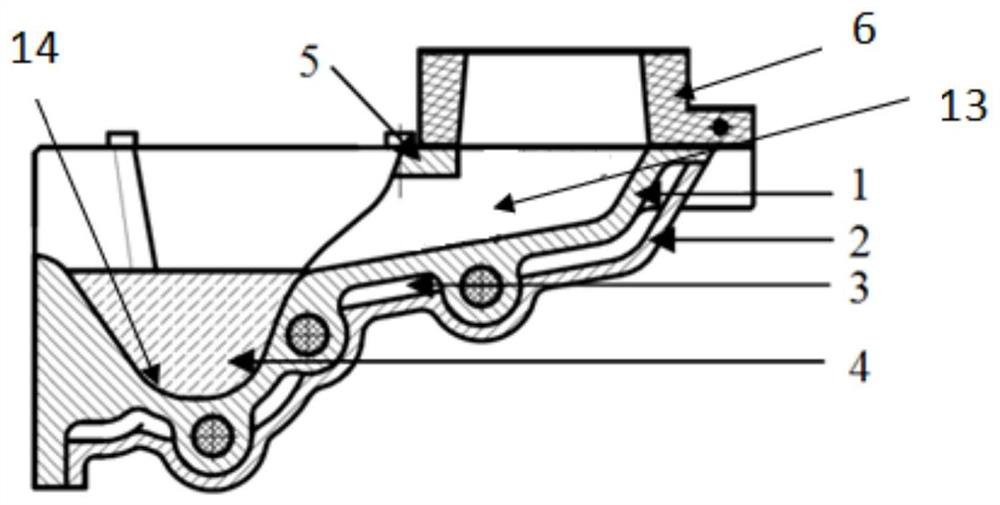

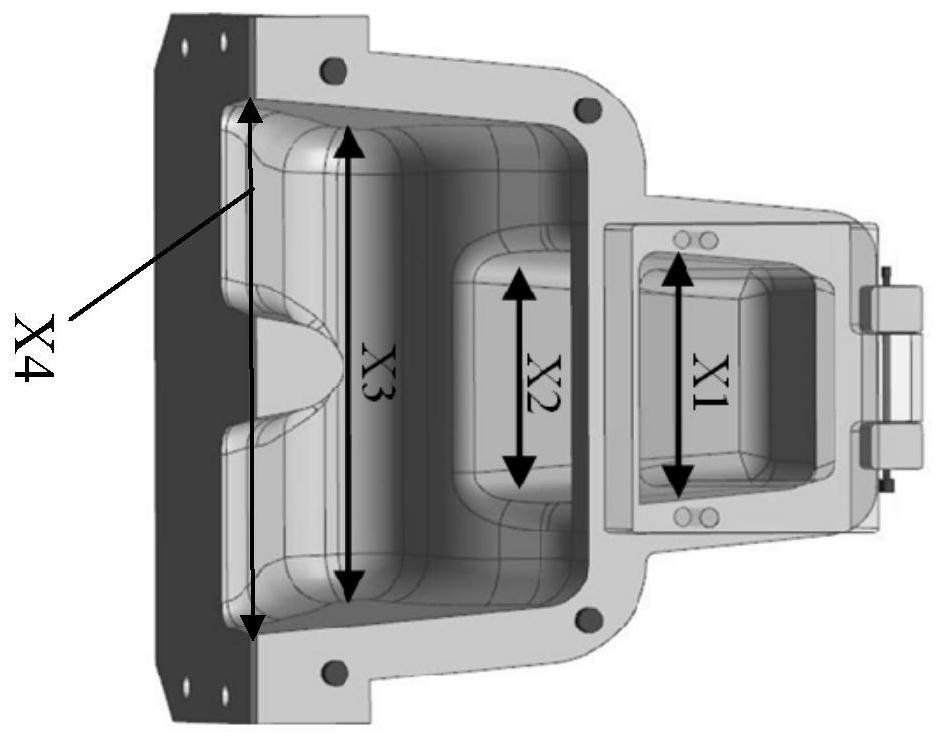

[0040] combine figure 1 and figure 2 , the hopper mainly includes a hopper body 1 , a hopper outer lining 2 and a sprue cup 6 . The thickness of the hopper body 1 is 12-15 mm, and the thickness of the outer lining of the hopper is 10-13 mm. The hopper body 1 and the hopper outer lining 2 are connected by screws, and there is a hollow structure between them. The hollow structure is filled with refractory and thermal insulation materials 3, and the hopper body 1 is equipped with a heating rod 9 and a temperature control element. The heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com