System and method for removing inorganic inert impurities in humus soil

A kind of humus soil and inorganic technology, which is applied in the direction of separation method, chemical instrument and method, and the feeding/discharging device of the settling tank, etc., can solve the problems of restricting the regeneration and utilization of humus soil resources, the perception and effect of humus soil, There are many broken stones and other problems, so as to realize the efficient utilization of resource classification, realize the efficient separation of mud and water, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

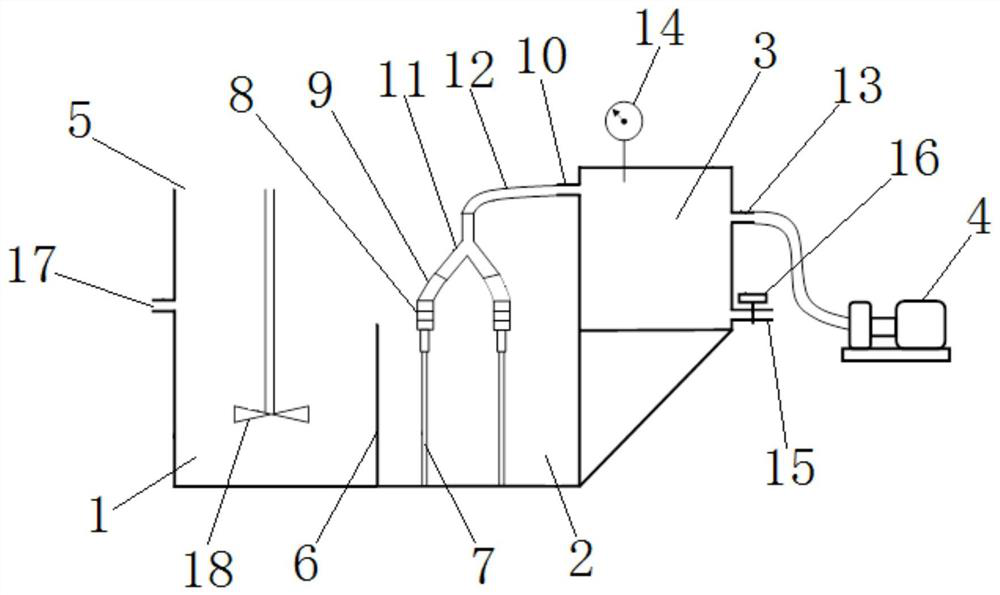

[0034] Such as figure 1 The shown system for removing inorganic inert impurities in humus includes a stirring tank 1, an overflow tank 2, a water collection chamber 3, and an air compressor 4 connected to the water collection chamber 3 in sequence. The top of the tank 1 is provided with a feed inlet 5, and the overflow tank 2 is provided with a drainage plate muddy water separation mechanism connected with the water collection chamber 3.

[0035] Wherein, the stirring tank 1 is provided with a stirring paddle 18 . An overflow plate 6 is provided between the stirring tank 1 and the overflow tank 2 .

[0036] The drain plate mud-water separation mechanism includes a drain plate 7 arranged in the overflow tank 2, a drain pipe plate joint 8 arranged on the top of the drain plate 7, and a drain pipe 9 connected to the drain pipe plate joint 8. The side of the water collection chamber 3 is provided with An overflow tank outlet 10 communicating with the drain pipe 9 is arranged. T...

Embodiment 2

[0042] In this embodiment, only one drainage plate mud-water separation mechanism is provided, and the drainage pipe 9 is directly connected to the drainage port 10 of the overflow pool. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com