Effective disinfection equipment for biomass energy steam box

A technology of biomass energy and disinfection equipment, which is applied in the direction of sanitary equipment for toilets, disinfection, construction, etc., and can solve the problems of bacterial impurities mixed in, no sterilization process, labor consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

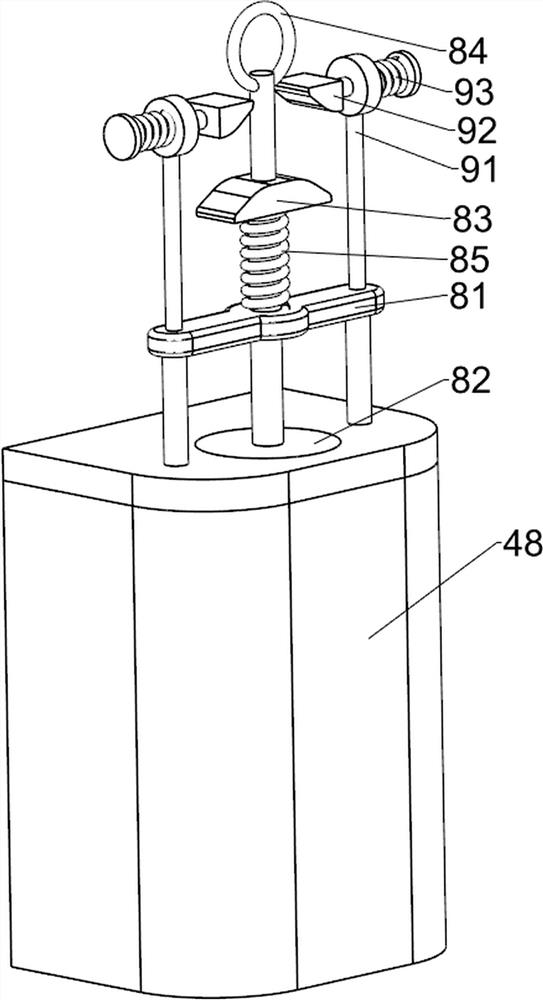

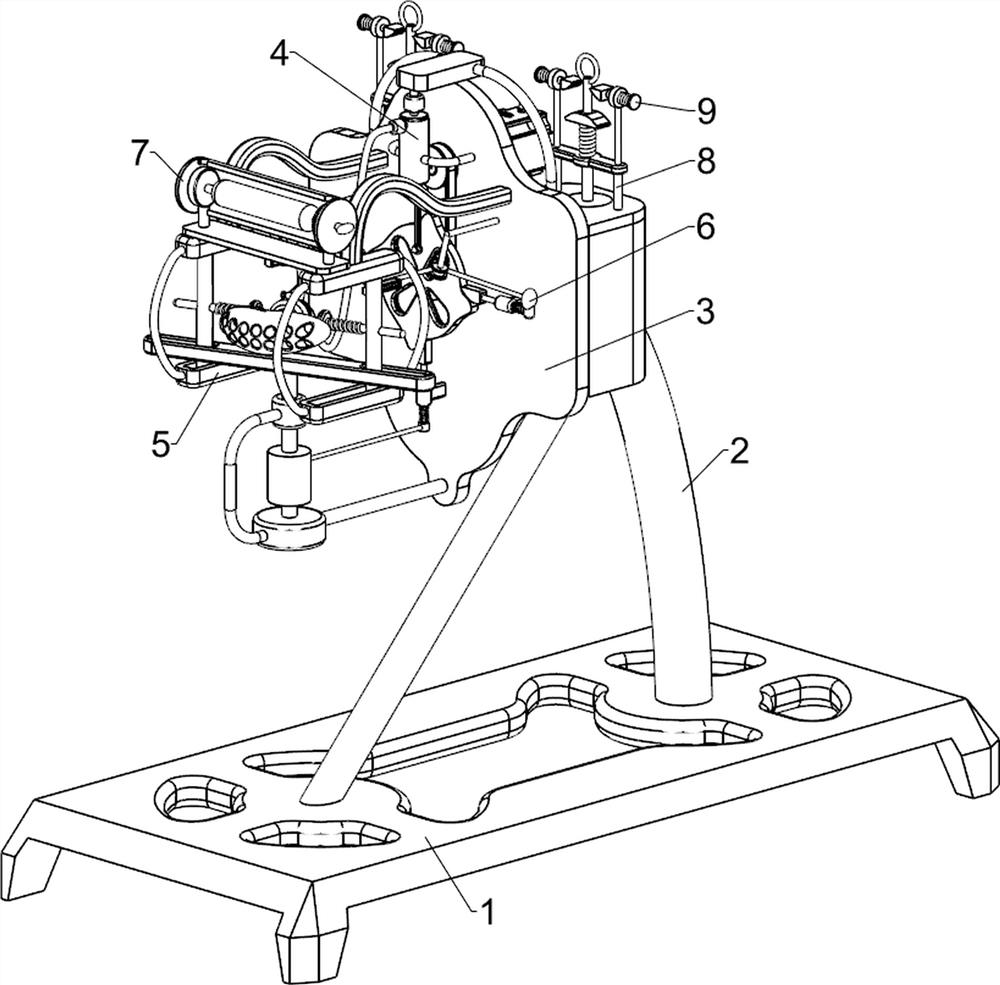

[0028] A kind of effective disinfection equipment for biomass energy steamer, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base plate 1, a support frame 2, a mounting plate 3, a spraying mechanism 4, a swing mechanism 5 and a lifting mechanism 6. The support frame 2 is connected to the upper part of the base plate 1, and the mounting plate 3 is connected to the front side of the upper part of the support frame 2. A spraying mechanism 4 is arranged between the plate 3 and the upper part of the support frame 2 , a rocking mechanism 5 is arranged between the front side of the mounting plate 3 and the spraying mechanism 4 , and a lifting mechanism 6 is arranged between the front side of the mounting plate 3 and the rocking mechanism 5 .

[0029]The spraying mechanism 4 includes a servo motor 41, a transmission assembly 42, a turntable 43, a first connecting rod 44, a second connecting rod 45, a piston 46, a cylinder 47, a water tank ...

Embodiment 2

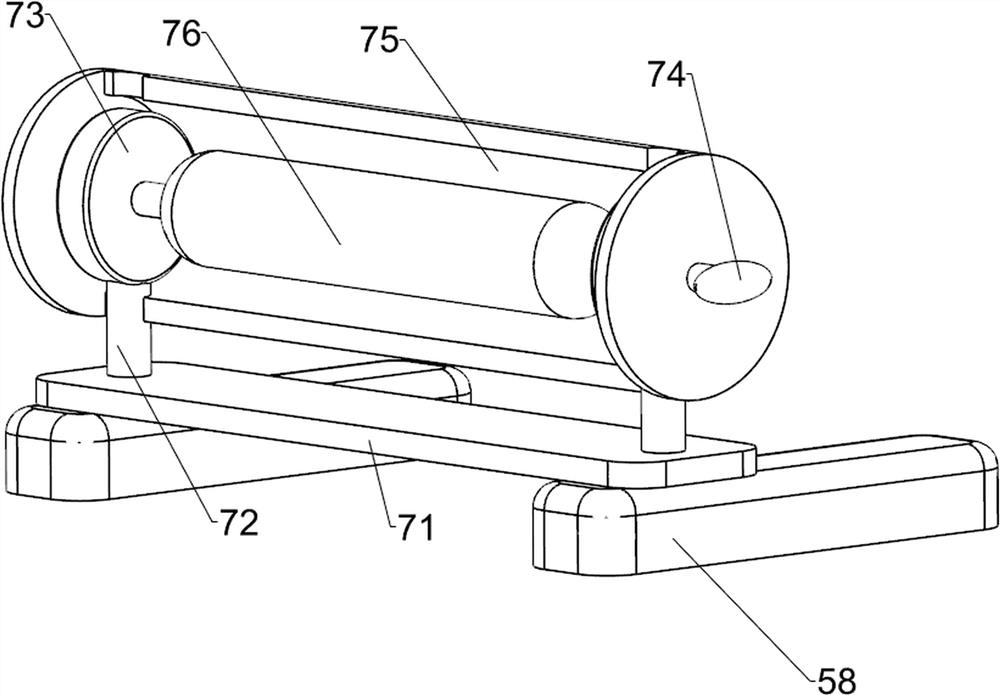

[0034] On the basis of Example 1, such as figure 1 , Figure 6 and Figure 7 Shown, also comprise ultraviolet lamp assembly 7, ultraviolet lamp assembly 7 comprises baffle plate 71, support column 72, connection block 73, turn handle 74, shield 75 and disinfection ultraviolet lamp 76, between the front side of chute seat 58 top A baffle 71 is connected between them, and the left and right sides of the upper part of the baffle 71 are connected with a support column 72, and the upper side of the support column 72 is connected with a connecting block 73, and a rotating handle 74 is connected between the connecting blocks 73, and the rotating handle 74 is left and right. A protective cover 75 is connected between the two sides, and a sterilizing ultraviolet lamp 76 is connected in the middle part of the handle 74 .

[0035] Turn on the disinfection ultraviolet lamp 76, and when the disinfectant solution is sprayed from the atomizing nozzle 413, turn the handle 74 clockwise to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com