A cherry tomato juice extraction equipment for the production of cherry tomato beverages

A technology for cherry tomatoes and beverages, which is applied in the field of cherry tomatoes juice extraction equipment for the production of cherry tomatoes beverages, and achieves the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

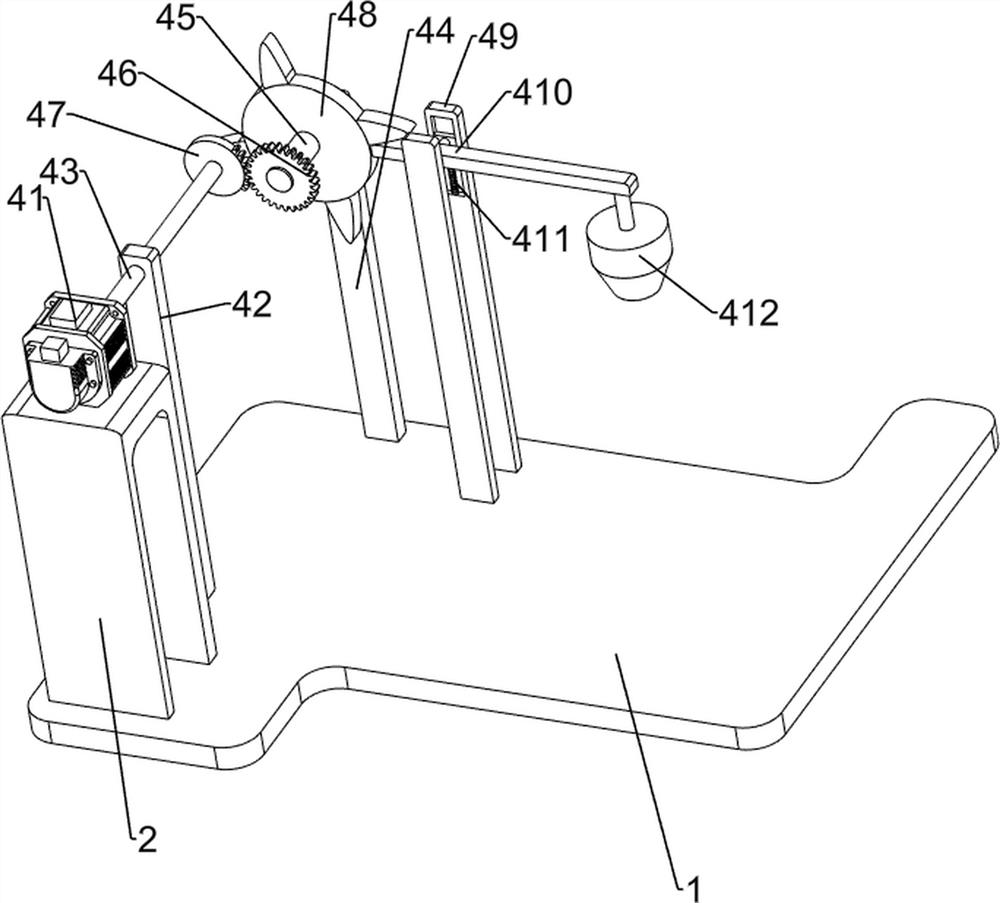

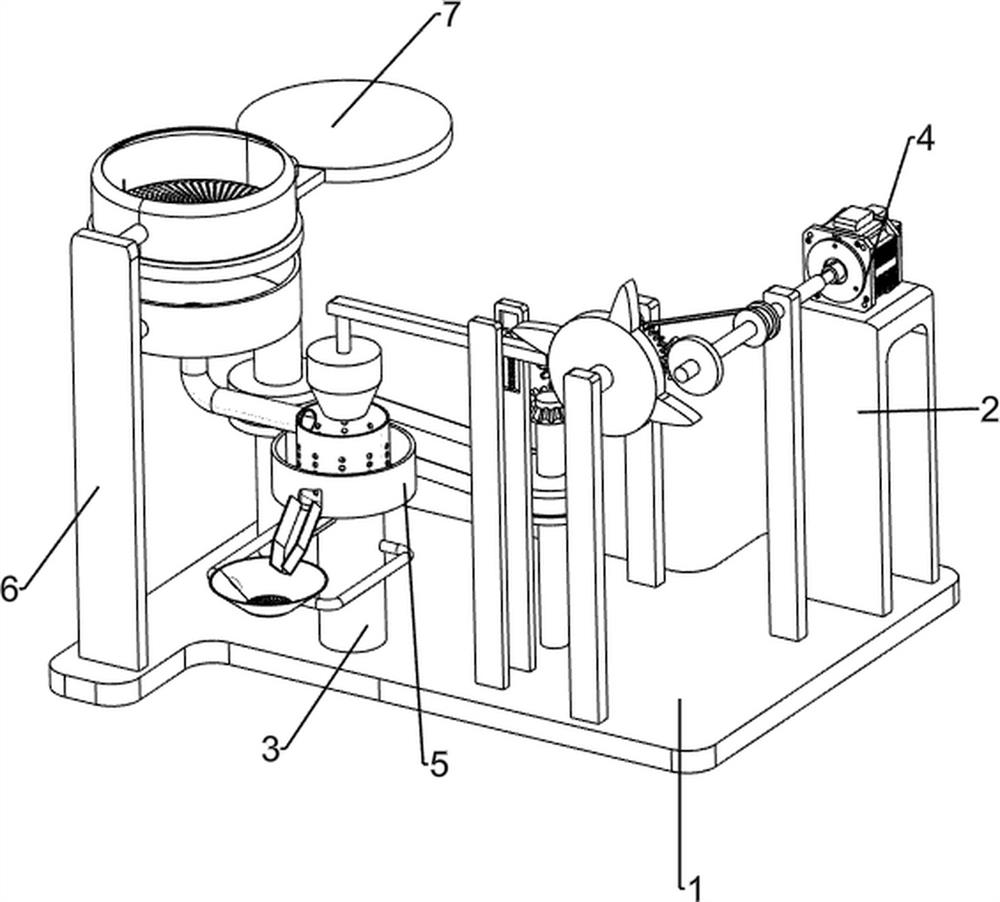

[0022] A cherry tomatoes juicer for making cherry tomatoes beverages, such as Figure 1-3 As shown, it includes a bottom plate 1, a support frame 2, a pillar 3, a pressing mechanism 4 and a placement mechanism 5. The top right rear side of the bottom plate 1 is connected with a support frame 2, the top left front side of the bottom plate 1 is connected with a pillar 3, and the support frame 2 is connected to the A pressing mechanism 4 is installed between the bottom plates 1 , and a placing mechanism 5 is installed on the pillars 3 .

[0023] The pressing mechanism 4 includes a servo motor 41, a supporting plate 42, a rotating shaft 43, a supporting block 44, an interlocking shaft 45, a spur gear 46, a missing gear 47, a cam 48, a first fixing plate 49, a pressing plate 410, a spring 411 and The lower pressing block 412, a servo motor 41 is installed on the top of the support frame 2, a support plate 42 is connected to the right rear side of the top of the bottom plate 1, a ro...

Embodiment 2

[0027] On the basis of Example 1, as figure 1 and Figure 4 As shown, it also includes an unloading mechanism 6, the unloading mechanism 6 includes a bracket 61, a lowering barrel 62 and a discharge pipe 63, a bracket 61 is connected to the left front side of the top of the bottom plate 1, and the bracket 61 is located on the left front side of the pillar 3, and the bracket 61 is connected with a lower material barrel 62 , and a discharge pipe 63 is connected between the bottom of the lower material barrel 62 and the upper part of the opening charging barrel 52 .

[0028] The cherry tomatoes can be poured into the lowering barrel 62, and the cherry tomatoes then enter the opening charging barrel 52 through the discharge pipe 63, so that there is no need to manually add the cherry tomatoes manually. Cut the material so that the cherry tomatoes enter the placing mechanism 5 .

Embodiment 3

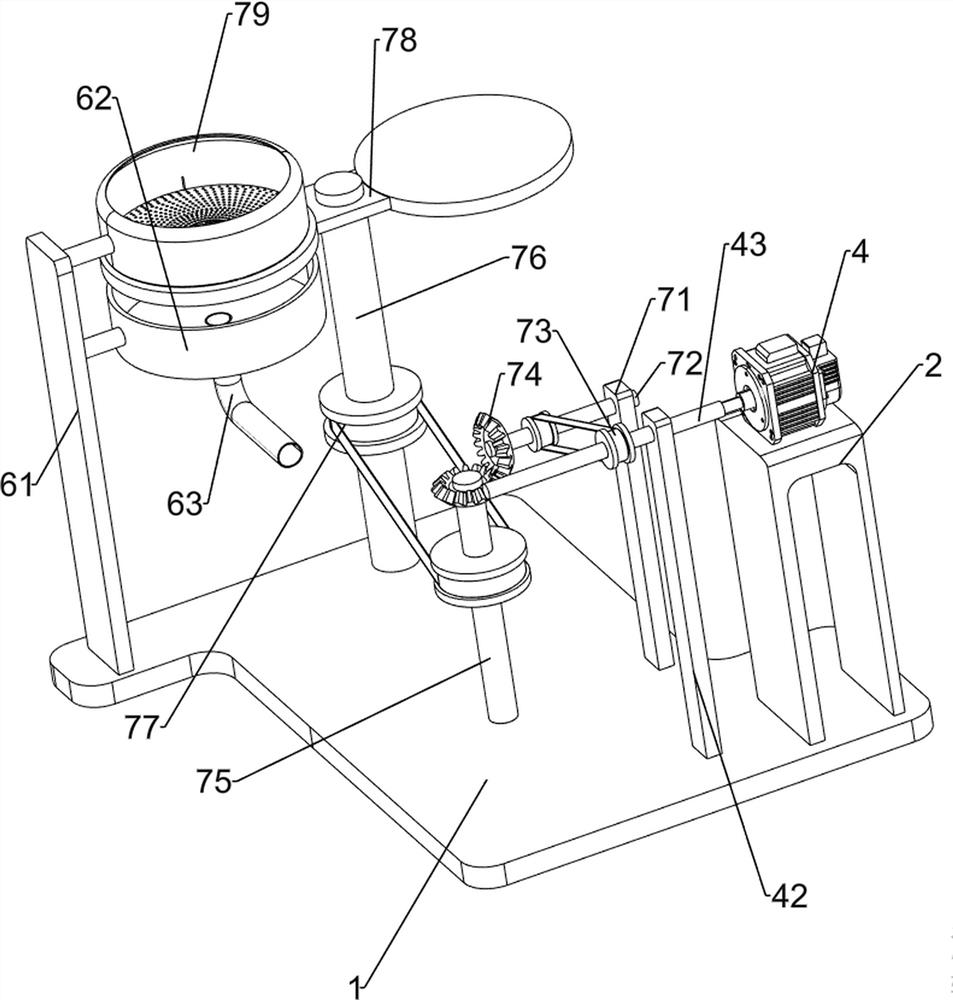

[0030] On the basis of Example 2, as figure 1 and Figure 4 As shown, it also includes a material blocking mechanism 7, and the material blocking mechanism 7 includes a second fixing plate 71, a rotating shaft 72, a first belt drive group 73, a bevel gear group 74, a rotating rod 75, a connecting shaft 76, a second belt The transmission group 77 , the baffle plate 78 and the lower hopper 79 , a second fixing plate 71 is connected to the rear side of the top of the bottom plate 1 , a rotating shaft 72 is rotatably connected to the second fixing plate 71 , and a rotating shaft 72 is connected to the rotating shaft 43 . The first belt drive group 73, the top of the bottom plate 1 is rotatably connected with a rotating rod 75, the rotating rod 75 is located on the front side of the second fixed plate 71, the bevel gear group 74 is connected between the rotating rod 75 and the rotating shaft 72, and the top of the bottom plate 1 is connected A connecting shaft 76 is rotatably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com