Artemisia sieversiana essential oil microcapsules taking purslane extract as wall material and preparation method thereof

A technology of Artemisia annua and microcapsules, applied in the field of Artemisia annua essential oil microcapsules and preparation thereof, can solve problems such as unseen microcapsule products, and achieve rich nutritional value and medicinal value, good safety and good activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

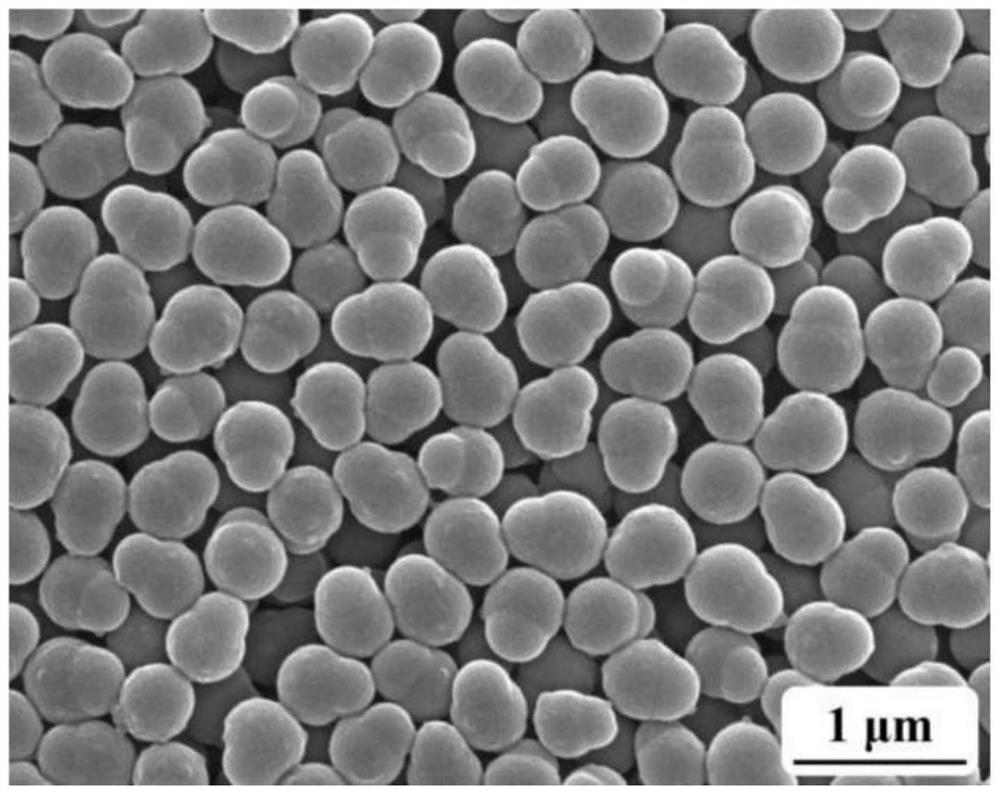

Image

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of Artemisia grandis essential oil microcapsules, and its technological process is as follows:

[0036] (1) preparation of purslane polysaccharide

[0037]Harvest fresh purslane, wash it, dry it naturally until the moisture content is lower than 10%, and crush it through an 80-mesh sieve. Use 2 times the mass of petroleum ether to reflux and degrease for 6 hours, filter the filter cake with suction, and dry the filter cake. Add distilled water to the filter cake, add 40 mL of distilled water per gram of filter cake, ultrasonically extract for 40 min at 70°C, filter the extract, and concentrate the filtrate by rotary evaporation at 50°C. Add 2 times the volume of absolute ethanol to the concentrated solution, ethanol overnight, filter with suction, wash the filter cake with absolute ethanol, ether and acetone in sequence, and dry to obtain purslane polysaccharide.

[0038] (2) Preparation of Artemisia grandis...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of Artemisia grandis essential oil microcapsules, and its technological process is as follows:

[0045] (1) preparation of purslane polysaccharide

[0046] Harvest fresh purslane, wash it, dry it naturally until the water content is lower than 10%, and crush it through a 50-mesh sieve. Reflux and degrease with 1.5 times the mass of petroleum ether for 8 hours, filter with suction to obtain a filter cake, and dry the filter cake. Add distilled water to the filter cake, add 40 mL of distilled water per gram of filter cake, conduct ultrasonic extraction for 60 min at 70°C, filter the extract, and concentrate the filtrate by rotary evaporation at 50°C. Add 2 times the volume of absolute ethanol to the concentrated solution, ethanol overnight, filter with suction, wash the filter cake with absolute ethanol, ether and acetone in sequence, and dry to obtain purslane polysaccharide.

[0047] (2) Preparation of Artem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com