Transplanting device for double-ridge green Chinese onions

A technology of double-row green onion and bottom plate, which is applied in the directions of transplanting machinery, application, planting method, etc., can solve problems such as low work efficiency and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

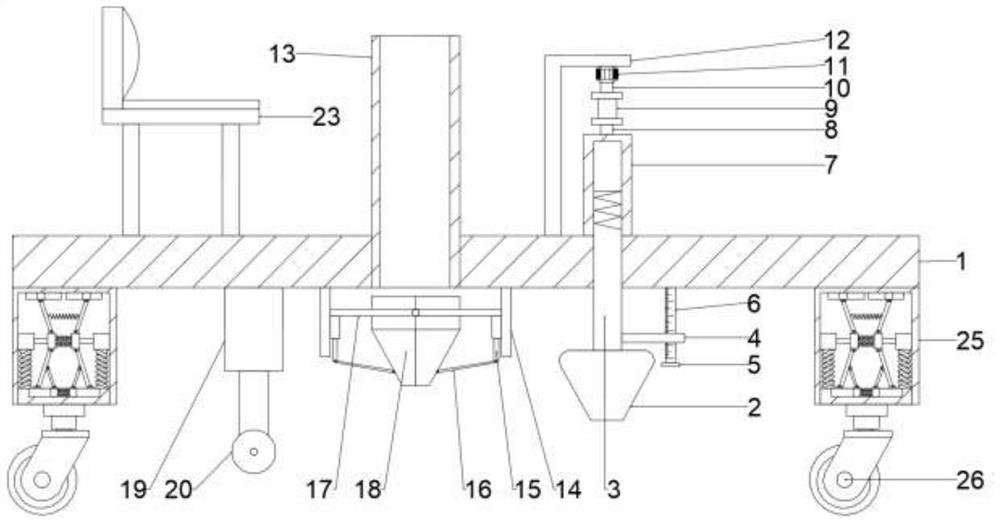

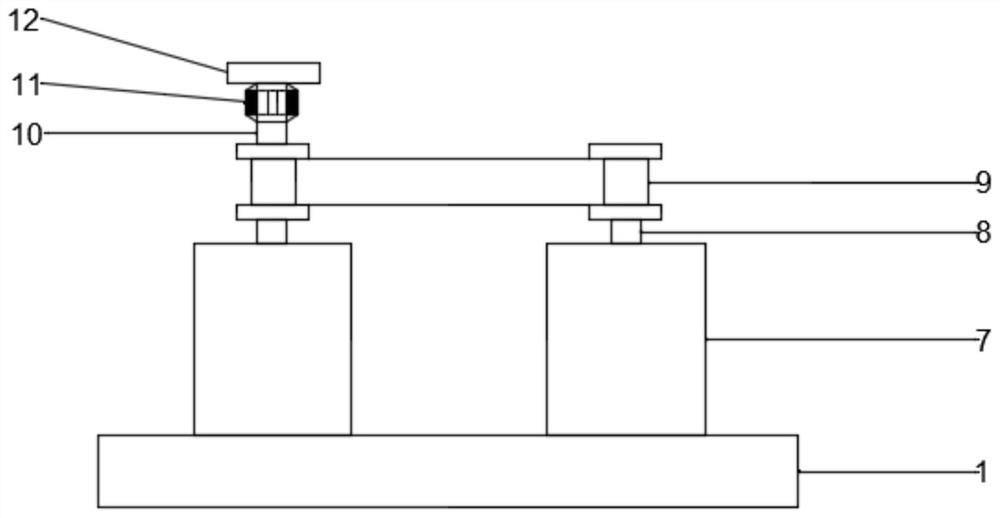

[0023] see Figure 1~4 , in an embodiment of the present invention, a transplanting device for green onions on double ridges includes a base plate 1, a seat 23 is fixedly connected to the upper surface of the left end of the base plate 1, and two transplanting devices are arranged on the right side of the seat 23. mechanism, the transplanting mechanism includes a sliding cylinder 13, a fixed plate 14, a first electric telescopic rod 15, a first connecting rod 16, a second connecting rod 17 and a duckbill 18, and the sliding cylinder 13 runs through the bottom plate 1 and is fixed thereto connection, the lower surface of the bottom plate 1 is fixedly connected with the fixed plate 14 symmetrically with the sliding cylinder 13 as the axis, the second connecting rod 17 is fixedly connected with the front and back symmetrically between the fixed plates 14, and the second connecting rod 17 is rotationally connected with Duckbill 18, the center of one side of the fixed plate 14 near...

Embodiment 2

[0028] see Figure 5 , on the basis of Embodiment 1, a cushioning mechanism is provided below the seat 23, and the cushioning mechanism includes a fixed frame 21, a first spring 22 and a second baffle 24, and the table legs of the seat 23 The lower surface is fixedly connected with a second baffle plate 24, and the second baffle plate 24 is located inside the fixed frame 21 and is slidably connected with its inner wall. The table legs of the seat 23 pass through the top of the fixed frame 21 and are slidably connected with it. The bottom end of the frame 21 is fixedly connected to the upper surface of the bottom plate 1 , the first spring 22 is fixedly connected to the lower surface of the second baffle plate 24 , and the other end of the first spring 22 is fixedly connected to the upper surface of the bottom plate 1 .

[0029] The working principle of the present invention is: the starter motor 11 drives the drive rod 10 to rotate, the drive rod 10 rotates to drive the belt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com