Device for preparing liquid spherical particles and method for preparing liquid spherical particles

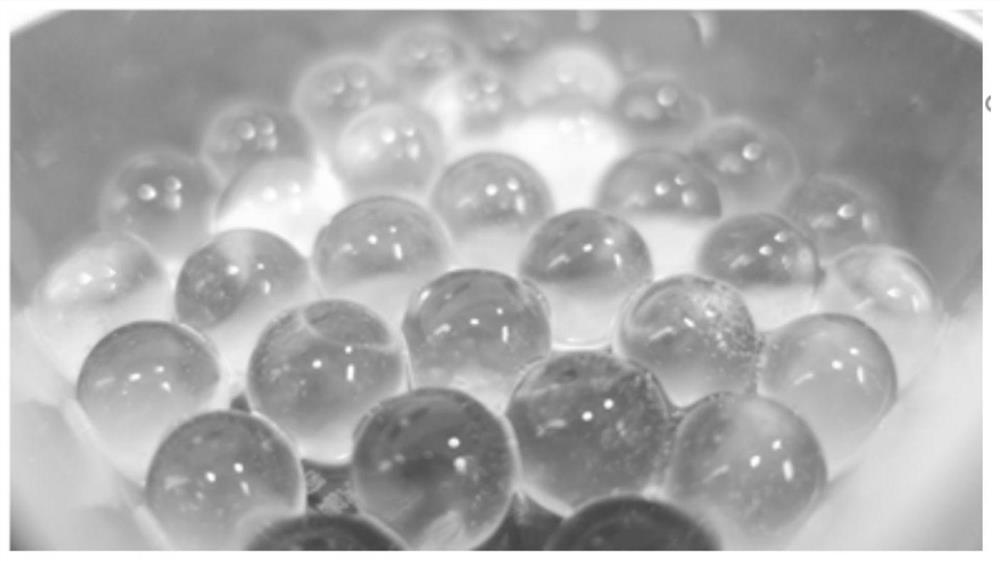

A technology for spherical particles and a preparation device, applied in the field of liquid spherical particle preparation and liquid spherical particle preparation device, can solve the problems of compression deformation of liquid spherical particles, affecting product appearance, poor sphericity, etc., to prevent compression deformation and avoid tailing phenomenon, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate understanding of the present invention, the present invention will be described more fully, and preferred embodiments of the present invention are given. However, the present invention can be implemented in many different forms, is not limited to the embodiments described herein. Conversely, the purpose of providing these examples is to make the understanding of the disclosure of the present invention more thoroughly.

[0027] All technical and scientific terms used herein are commonly understood by those skilled in the art of the present invention, unless otherwise defined. The terminology used in the specification of the present invention is intended to describe the embodiments of the specific embodiments, and is not intended to limit the invention. The terms "and / or" as used herein include any and all combinations of one or more related list items.

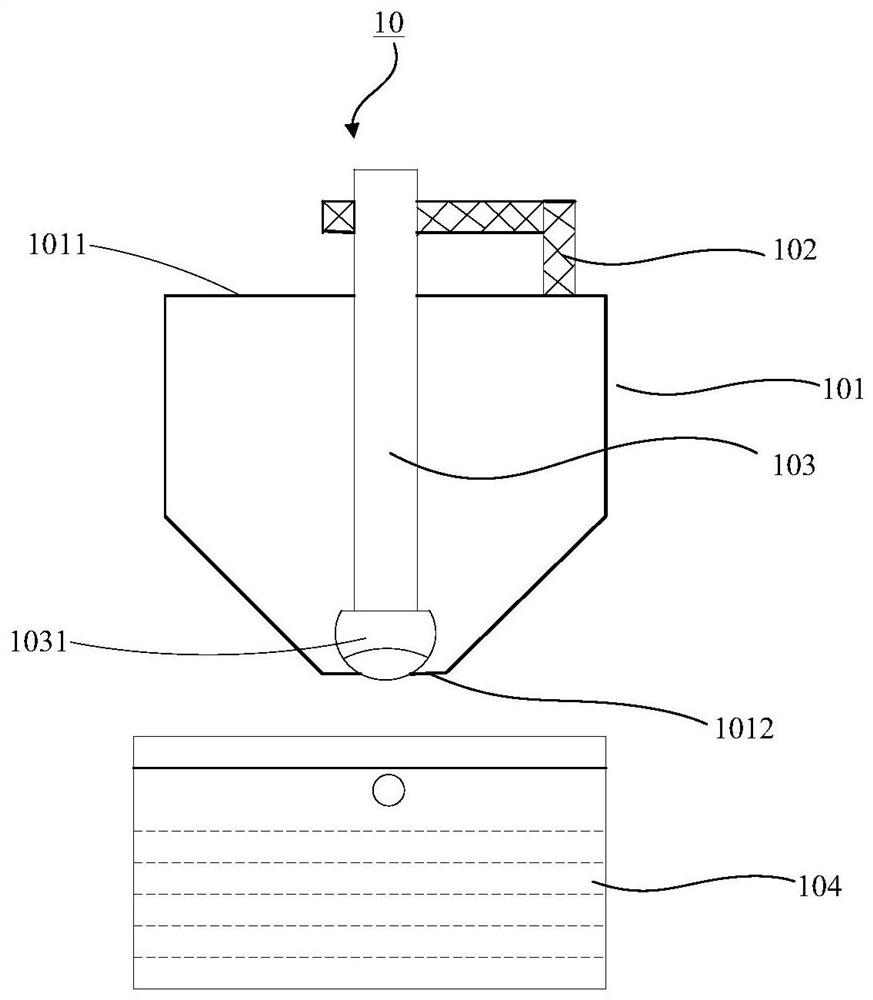

[0028] Means a liquid preparation of spherical particles embodiment 10 of the present invention, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com