Burner with outer outer peripheral soft fire, stove and control method

A burner and outer ring technology, applied in the field of stoves, can solve the problems of low combustion efficiency, easy to burn pots, and less air supply, and achieve high combustion thermal efficiency, good cooking experience, and even heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

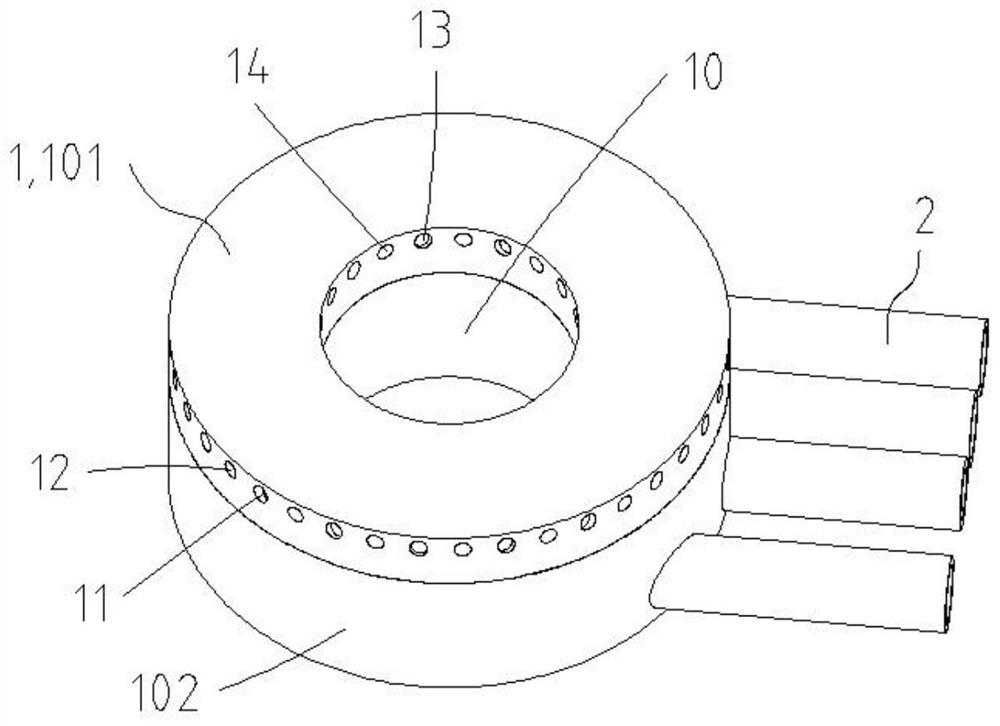

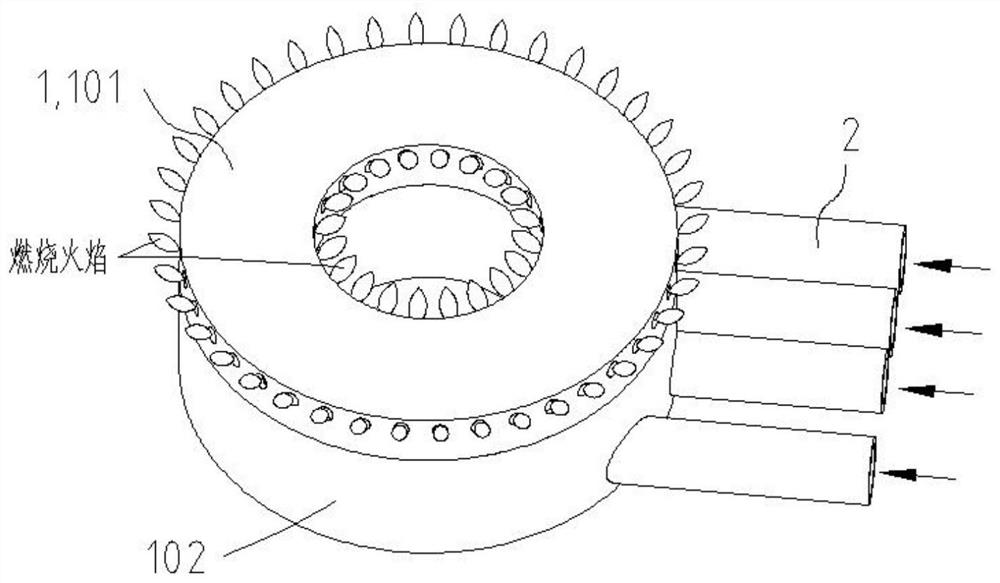

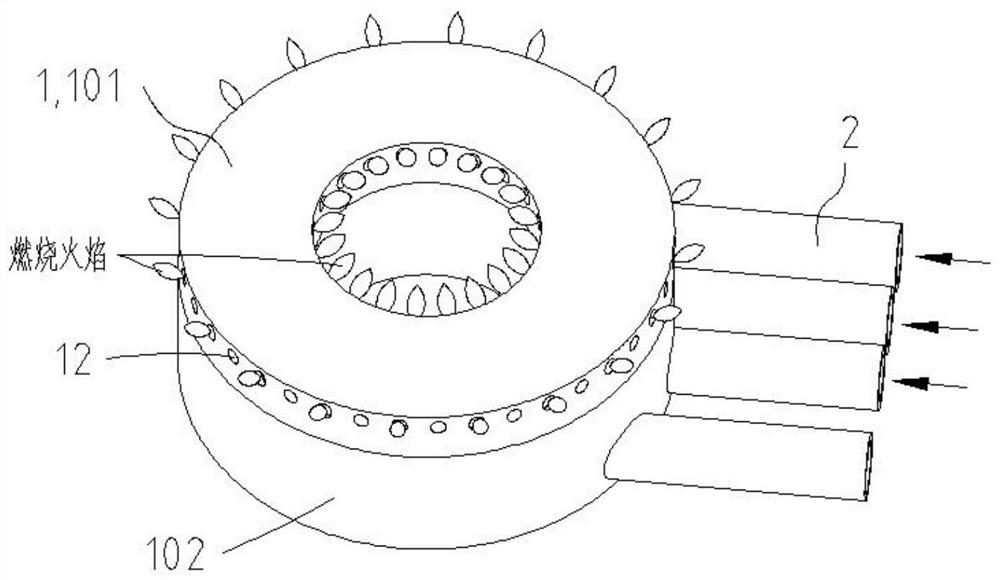

[0045] see figure 1 , this embodiment provides a burner with a small outer ring, including a burner body 1 with a central through hole 10, and a number of ejector tubes 2, wherein a number of staggered arrangements are arranged on the outer wall of the burner body 1 in the circumferential direction. Or the outer ring large fire hole 11 and the outer ring small fire hole 12 arranged side by side up and down, the outer ring large fire hole 11 communicates with the first injection pipe 2, and the outer ring small fire hole 12 communicates with the second injection pipe 2. In this embodiment, the burner body 1 includes a fire cover 101 and a burner head 102. The outer ring large fire holes 11 and the outer ring small fire holes 12 are staggered along the circumferential direction or arranged side by side up and down with the outer wall of the fire cover 101. And the outer ring large fire hole 11 communicates with the first ejector pipe 2 through the first gas mixing chamber of the...

Embodiment 2

[0072] see Figure 12 The difference between this embodiment and Embodiment 1 is that the burner omits the fourth injection tube 2 and the very small fire hole 14 located on the inner wall of the burner body 1, so that the burner has at least three stages of fire, Ensure that the range of firepower distribution is large when the fire is low, and it will not be too concentrated at the bottom of the pot, so that the bottom of the pot is heated more evenly, and the cooking experience is better. At the same time, the overall structure of the burner is simpler and the manufacturing cost is lower.

[0073] Combine below Figure 12 To illustrate the fire gear of the burner in this embodiment:

[0074] The burner has only two rings of fire, namely the outer ring fire and the inner ring fire, but the outer ring fire includes the outer ring fire and the outer ring small fire, and the inner ring fire includes the inner ring fire. By combining the outer ring fire and the inner ring fire,...

Embodiment 3

[0089] see Figure 14 The difference between this embodiment and Embodiment 2 is that the burner omits the third injection pipe 2 and the small inner ring fire holes 13 located on the inner side wall of the burner body 1, so that the burner only has an outer ring fire hole. , but the outer ring fire includes the outer ring small fire and the outer ring large fire, so that the firepower distribution range is large when the fire is low, and it will not be too concentrated on the bottom of the pot, so that the bottom of the pot is heated more evenly, and the cooking experience is better. The structure is simpler and the manufacturing cost is lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com