Preparation process of thermosensitive color-changing pencil lead

A heat-sensitive color changing and preparation process technology is applied in the field of heat-sensitive color-changing lead core preparation technology, which can solve the problems that lead cores do not have color change, are not easy to color, and are easy to break, so as to achieve non-toxic refills, various colors, and smooth writing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

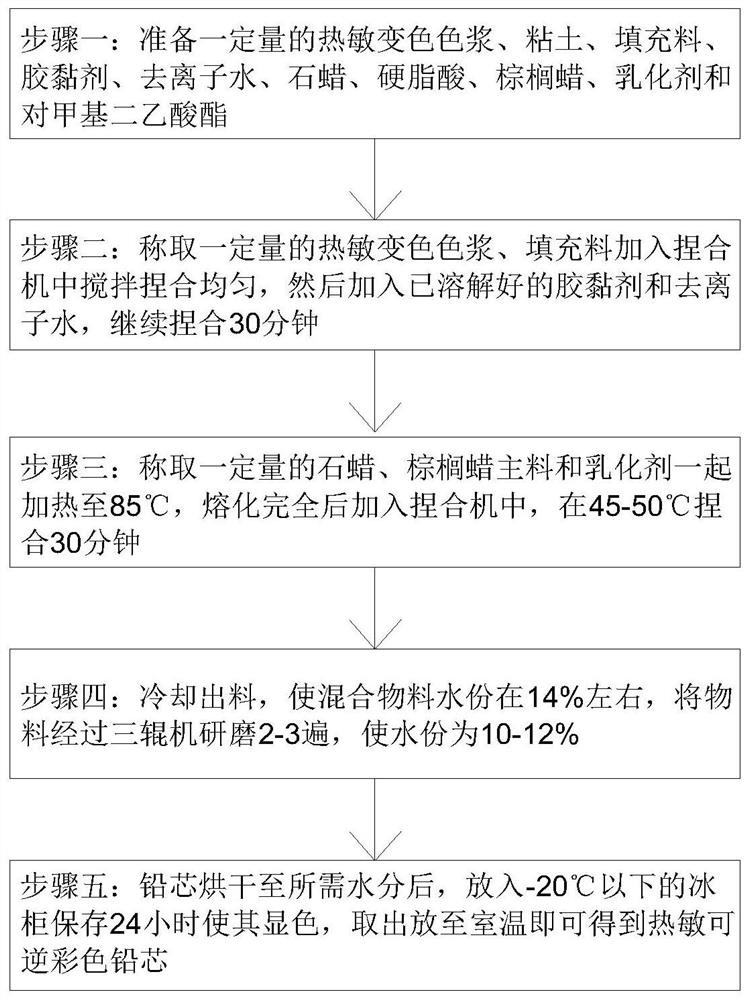

[0037] Process steps:

[0038] Step 1: Prepare a certain amount of thermosensitive color-changing color paste, clay, filler, adhesive, deionized water, paraffin wax, stearic acid, carnauba wax, emulsifier and p-methyl diacetate;

[0039] Step 2: Weigh a certain amount of heat-sensitive color-changing color paste and filler and add it into the kneader to stir and knead evenly, then add the dissolved adhesive and deionized water, and continue kneading for 30 minutes;

[0040] Step 3: Weigh a certain amount of paraffin wax, carnauba wax main ingredients and emulsifier and heat them to 85°C, add them into the kneader after melting completely, and knead at 45-50°C for 30 minutes;

[0041] Step 4: Cool and discharge the material so that the water content of the mixed material is about 14%, and grind the material 2-3 times through a three-roller machine to make the water content 10-12%;

[0042] Step 5: After the lead core is dried to the required moisture, store it in a freezer bel...

Embodiment 2

[0045] Process steps:

[0046] Step 1: Prepare a certain amount of thermosensitive color-changing color paste, clay, filler, adhesive, deionized water, paraffin wax, stearic acid, carnauba wax, emulsifier and p-methyl diacetate;

[0047] Step 2: Weigh a certain amount of heat-sensitive color-changing color paste and filler and add it into the kneader to stir and knead evenly, then add the dissolved adhesive and deionized water, and continue kneading for 30 minutes;

[0048] Step 3: Weigh a certain amount of paraffin wax, carnauba wax main ingredients and emulsifier and heat them to 85°C, add them into the kneader after melting completely, and knead at 45-50°C for 30 minutes;

[0049] Step 4: Cool and discharge the material so that the water content of the mixed material is about 14%, and grind the material 2-3 times through a three-roller machine to make the water content 10-12%;

[0050] Step 5: After the lead core is dried to the required moisture, store it in a freezer bel...

Embodiment 3

[0053] Process steps:

[0054] Step 1: Prepare a certain amount of thermosensitive color-changing color paste, clay, filler, adhesive, deionized water, paraffin wax, stearic acid, carnauba wax, emulsifier and p-methyl diacetate;

[0055] Step 2: Weigh a certain amount of heat-sensitive color-changing color paste and filler and add it into the kneader to stir and knead evenly, then add the dissolved adhesive and deionized water, and continue kneading for 30 minutes;

[0056] Step 3: Weigh a certain amount of paraffin wax, carnauba wax main ingredients and emulsifier and heat them to 85°C, add them into the kneader after melting completely, and knead at 45-50°C for 30 minutes;

[0057] Step 4: Cool and discharge the material so that the water content of the mixed material is about 14%, and grind the material 2-3 times through a three-roller machine to make the water content 10-12%;

[0058] Step 5: After the lead core is dried to the required moisture, store it in a freezer bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com