Waterfall flow type special jig for chemical etching and preparation method of ultrathin glass

A chemical etching and ultra-thin glass technology, applied in the field of chemical etching thinning, can solve the problems of high fragmentation rate, low processing yield, poor plate thickness uniformity, etc., and achieve the best polishing effect, less reaction time, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of ultra-thin glass, which includes a special jig for waterfall flow chemical etching as described above, and the steps are as follows:

[0038] Step 1: first use the conventional etching process to thin the glass to a thickness of 0.3mm;

[0039] Step 2: Select polishing powder with a particle size between 0.7-0.9um, and then perform fine polishing on the 0.3mm thin glass in step 1 to completely remove scratches, dirt and other defects on the glass surface to ensure that the surface of the thin glass is After there is no defect and the frame effect is good, the waterfall flow chemical etching operation is carried out;

[0040] Step 3: Perform waterfall chemical etching operation:

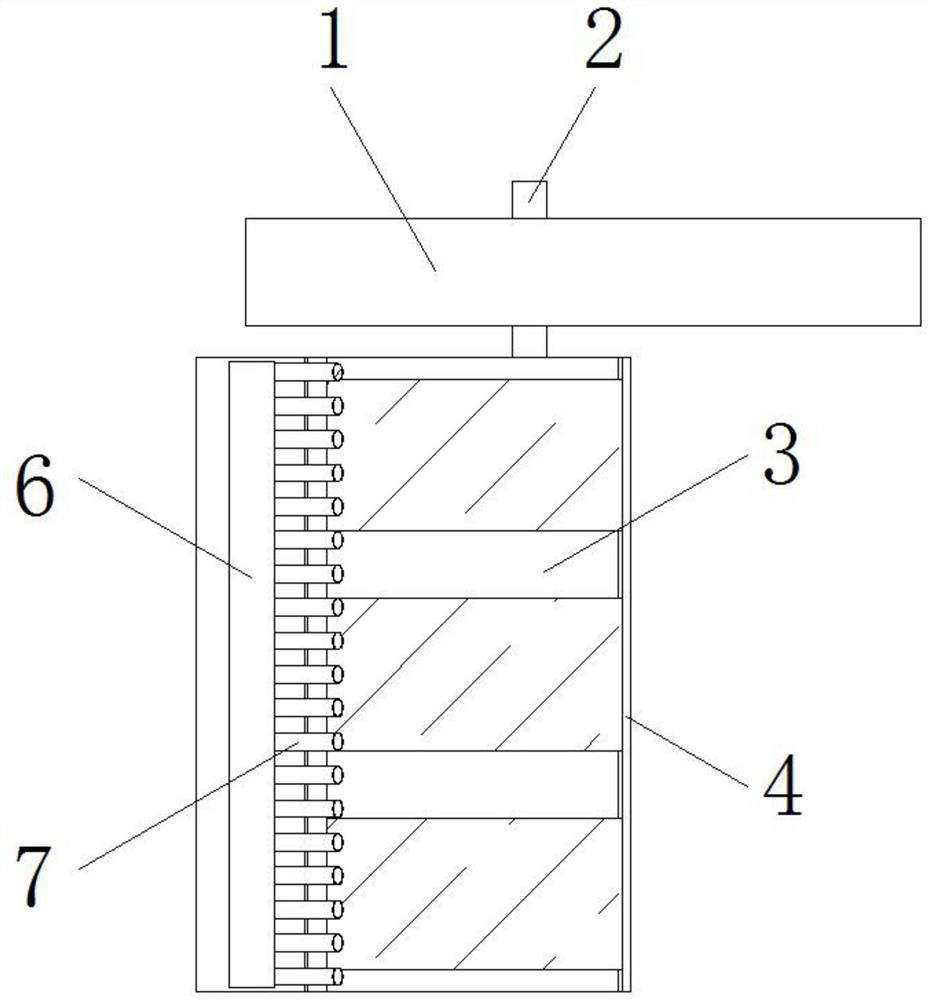

[0041] (a). The thin glass after fine polishing in step 2 is mounted on the support frame 3, and a plurality of thin glasses can be placed in parallel on the support frame 3 according to the size of the thin glass;

[0042] (b). Adjust the inclination angle of the supp...

Embodiment 2

[0053] A preparation method of ultra-thin glass, which includes a special jig for waterfall flow chemical etching as described above, and the steps are as follows:

[0054] Step 1: first use the conventional etching process to thin the glass to a thickness of 0.3mm;

[0055] Step 2: Select polishing powder with a particle size between 0.7-0.9um, and then perform fine polishing on the 0.3mm thin glass in step 1 to completely remove scratches, dirt and other defects on the glass surface to ensure that the surface of the thin glass is After there is no defect and the frame effect is good, the waterfall flow chemical etching operation is carried out;

[0056] Step 3: Perform waterfall chemical etching operation:

[0057] (a). The thin glass after fine polishing in step 2 is mounted on the support frame 3, and a plurality of thin glasses can be placed in parallel on the support frame 3 according to the size of the thin glass;

[0058] (b). Adjust the inclination angle of the supp...

Embodiment 3

[0069] A preparation method of ultra-thin glass, which includes a special jig for waterfall flow chemical etching as described above, and the steps are as follows:

[0070] Step 1: first use the conventional etching process to thin the glass to a thickness of 0.3mm;

[0071] Step 2: Select polishing powder with a particle size between 0.7-0.9um, and then perform fine polishing on the 0.3mm thin glass in step 1 to completely remove scratches, dirt and other defects on the glass surface to ensure that the surface of the thin glass is After there is no defect and the frame effect is good, the waterfall flow chemical etching operation is carried out;

[0072] Step 3: Perform waterfall chemical etching operation:

[0073] (a). The thin glass after fine polishing in step 2 is mounted on the support frame 3, and a plurality of thin glasses can be placed in parallel on the support frame 3 according to the size of the thin glass;

[0074] (b). Adjust the inclination angle of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com