Mechanical sandbag automatic filling machine equipment

A technology of automatic filling and sandbags, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reducing operation intensity, and achieve the effects of reducing operation intensity, fast installation speed, and less human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

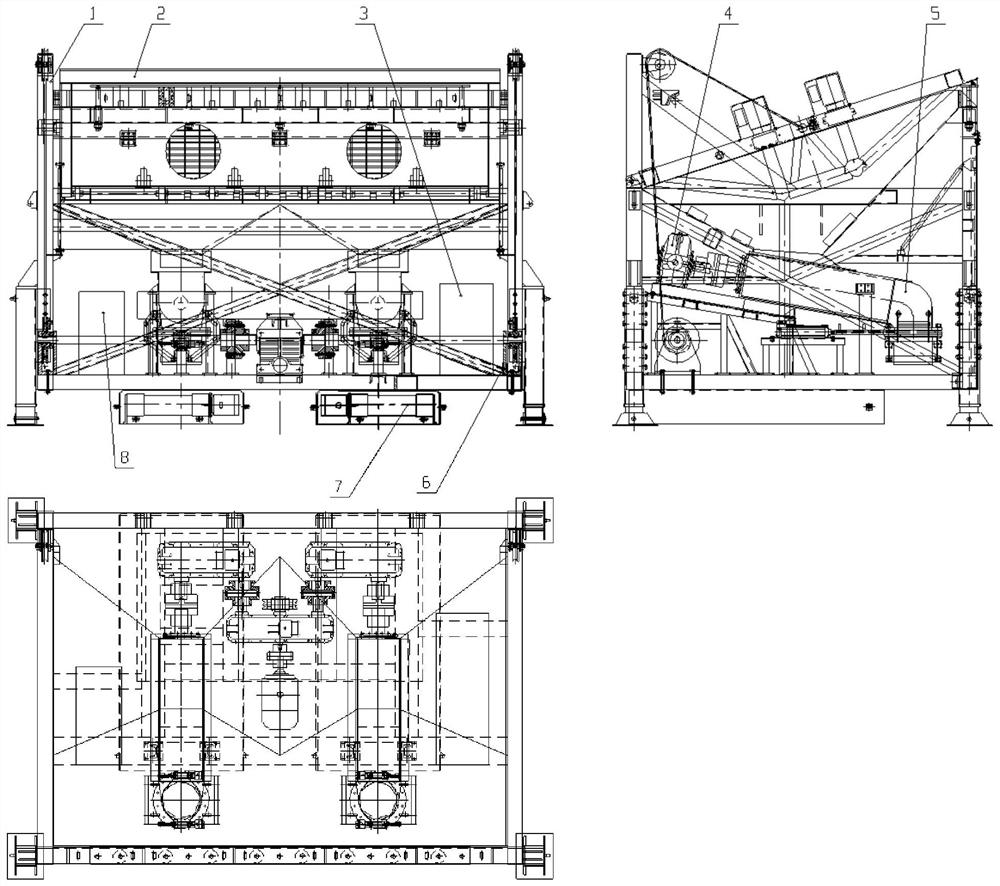

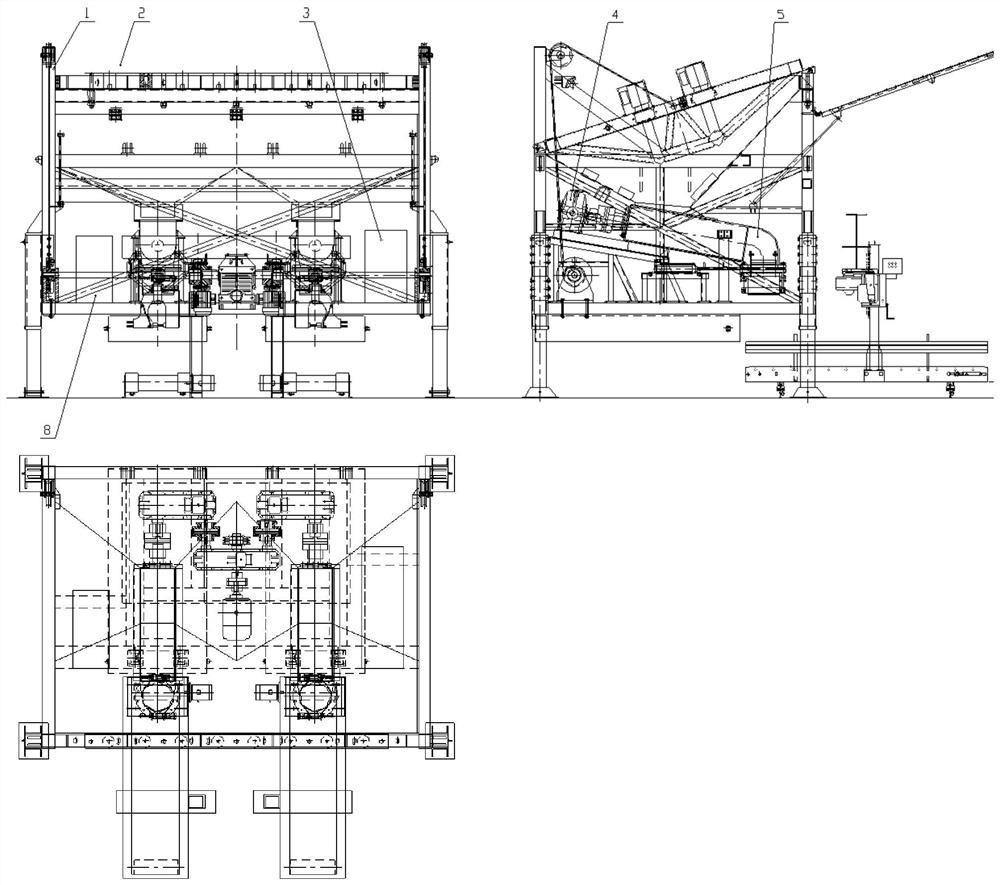

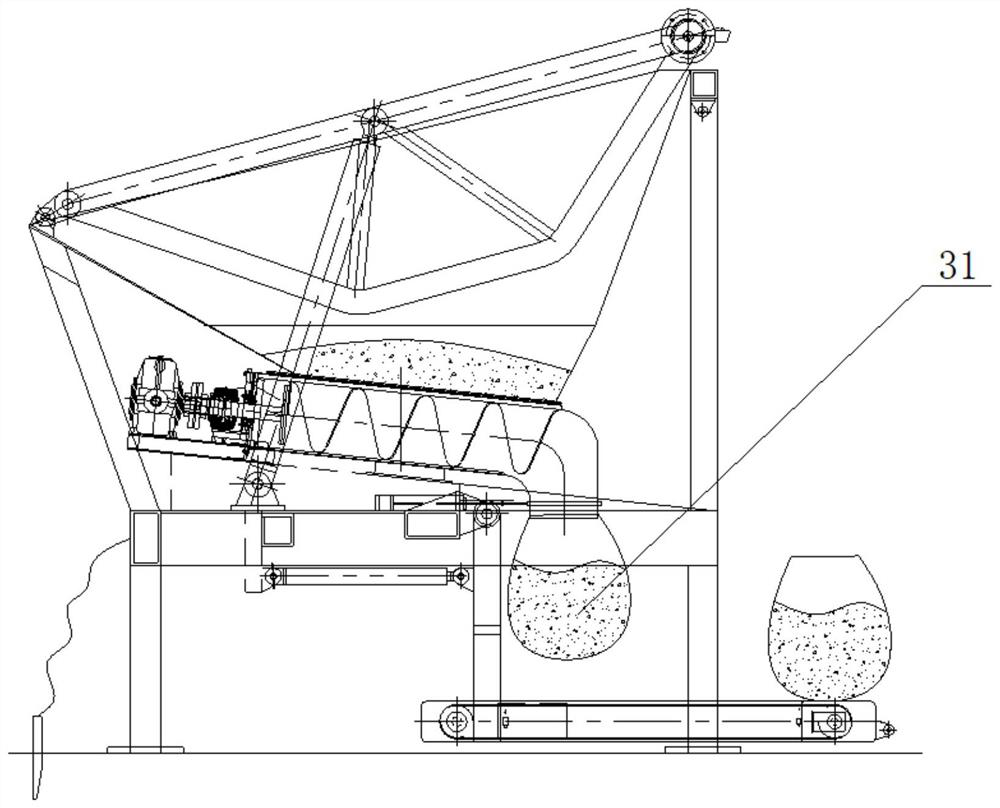

[0036] The invention provides a mechanized sandbag automatic filling machine equipment, such as figure 1 , Figure 4 As shown, it includes a hopper assembly 1, a vibrating filter bucket assembly 2, a screw conveying device 4, a bag clamping mechanism 5, an overturning mechanism assembly 6 and a bag sewing conveyor 7.

[0037] The vibrating filter bucket assembly 2 is hinged on the hopper assembly 1, and is turned over at a certain angle driven by the turning mechanism; the lower interface of the hopper assembly 1 is connected with the screw conveying device 4, and the soil material filtered by the vibrating filter bucket assembly 2 Through the hopper assembly 1 with a certain slope, it enters the screw conveying device 4 under the action of gravity; the external sandbag 31 is clamped at the outlet 19 of the screw conveying device 4 through the bag clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com