Sand blasting system for aluminum profile sand blasting

An aluminum profile and sandblasting technology, which is applied to the processing device of used abrasives, abrasive jetting machine tools, abrasives, etc., can solve the problems of inability to guarantee the quality of aluminum profiles, high labor intensity of workers, and reduced sandblasting efficiency of aluminum profiles. , to achieve the effect of reducing workload, improving efficiency, and improving the efficiency of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them.

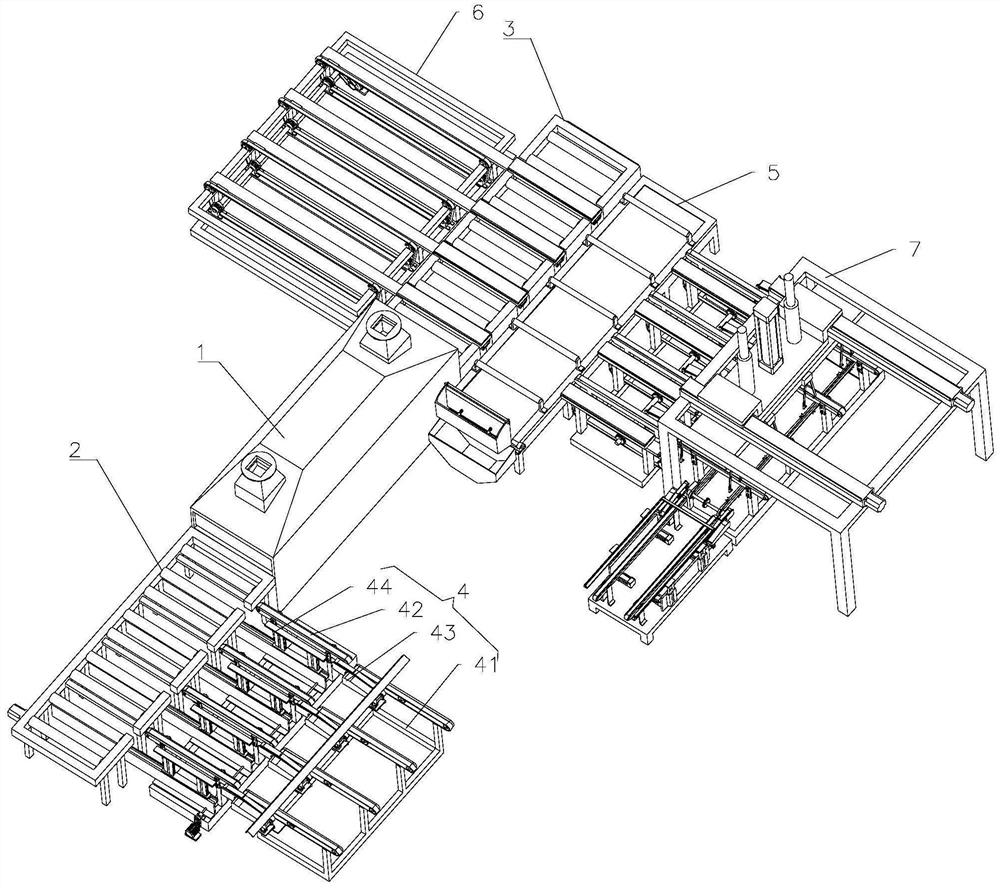

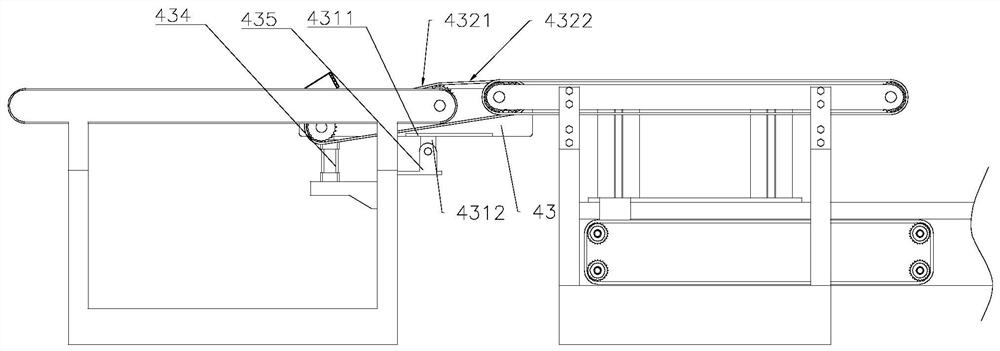

[0035] Such as Figure 1-11 As shown, a sandblasting system for sandblasting aluminum profiles, including: sandblasting machine 1, conveying frame 2 before sandblasting, and conveying frame 3 after sandblasting, conveying frame 2 before sandblasting and conveying frame after sandblasting 3 are respectively arranged at the front and rear ends of the sand blasting machine 1, and also includes: a feeding device 4, the feeding device 4 includes a first conveying mechanism 41, a second conveying mechanism 42, a first arrangement mechanism 43 and a first transfer mechanism 44, The first arrangement mechanism 43 is used to equidistantly arrange the aluminum profiles on the first conveying mechanism 41 to the second conveyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com