Chip packaging structure and packaging method

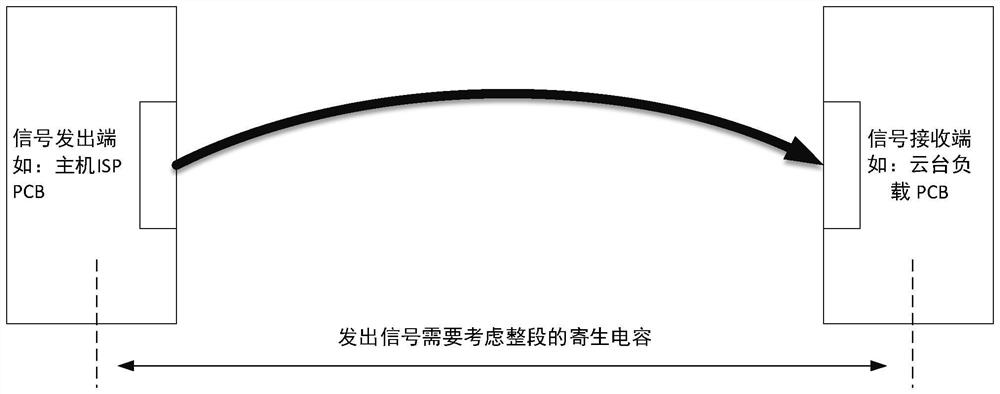

A technology of chip packaging structure and packaging method, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as poor signal performance and poor signal quality, and achieve improved connection reliability and reduced Volume, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] image 3 It is a structural schematic diagram of a section of a chip package structure in the present invention. Figure 4 It is a structural schematic diagram of the top of the chip package structure in the present invention, wherein the chip 20 is in a see-through state. combine image 3 and Figure 4 shown in .

[0072] In one embodiment of the present invention, a chip packaging structure is provided, including: a substrate 10 , a chip 20 and a protective layer 30 . Wherein, the substrate 10 has a first connection portion and a second connection portion 11 , and the first connection portion and the second connection portion 11 are electrically connected through the internal circuit 13 of the substrate 10 . Wherein, the second connection portion 11 is a through hole penetrating the substrate 10 , and an electroplating layer with a connection hole is disposed in the through hole. The chip 20 is disposed on the substrate 10 and is electrically connected to the fir...

Embodiment 2

[0112] Correspondingly, in one embodiment of the present invention, a packaging method of the chip 20 is also provided, and the method in the second embodiment can manufacture the chip packaging structure described in the first embodiment. The specific plan is as follows:

[0113] see Figure 8 , combined with image 3 and Figure 4 , in one embodiment of the present invention, also provides a kind of packaging method of chip 20, comprise:

[0114] Step S101: disposing the chip 20 on the substrate 10, so that the chip 20 is electrically connected to the first connection part on the substrate 10; wherein, the substrate 10 has a first connection part and a second connection part 11, and the first connection part and the second connection part The two connecting parts 11 are electrically connected through the internal circuit 13 of the substrate 10; wherein, the second connecting part 11 is a through hole penetrating the substrate 10, and an electroplating layer with a connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com