Circuit for direct-current synchronous boosting

A DC synchronization and circuit technology, which is applied in the direction of DC power input conversion to DC power output, electrical components, and adjustment of electrical variables, can solve the problems of lack of flexibility and poor consistency of current-limiting protection points, and achieve short-circuit monitoring and protection. , improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Attached below Figure 3-5 , the specific embodiment of the present invention will be further described in detail.

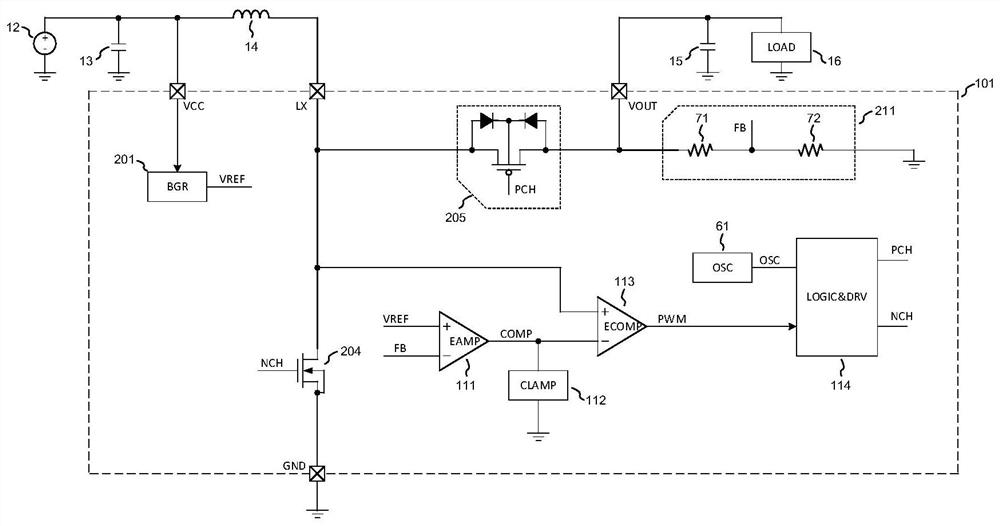

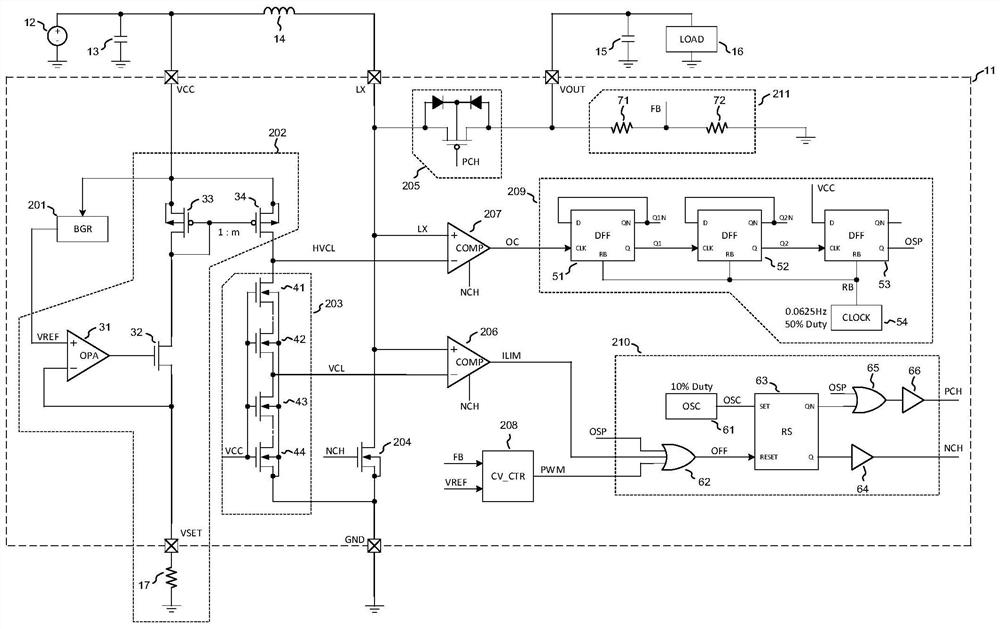

[0069] see image 3 , image 3 Shown is a schematic structural diagram of a DC synchronous step-up circuit in an embodiment of the present invention. Such as image 3 As shown, the DC synchronous boost circuit of the present invention includes a boost control chip 11 , an input power source 12 , an input capacitor 13 , an energy storage inductor 14 , an output capacitor 15 , a load 16 and an external programming resistor 17 .

[0070] The boost control chip 11 includes an overcurrent protection module 207, a current limiting protection module 206, a power supply port VCC, a port LX, an output port output terminal VOUT, a current limiting setting terminal VSET, and a ground terminal GND; the port LX terminal is connected to To one end of the energy storage inductance, the other end of the energy storage inductance 14 is connected to the power port VCC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com