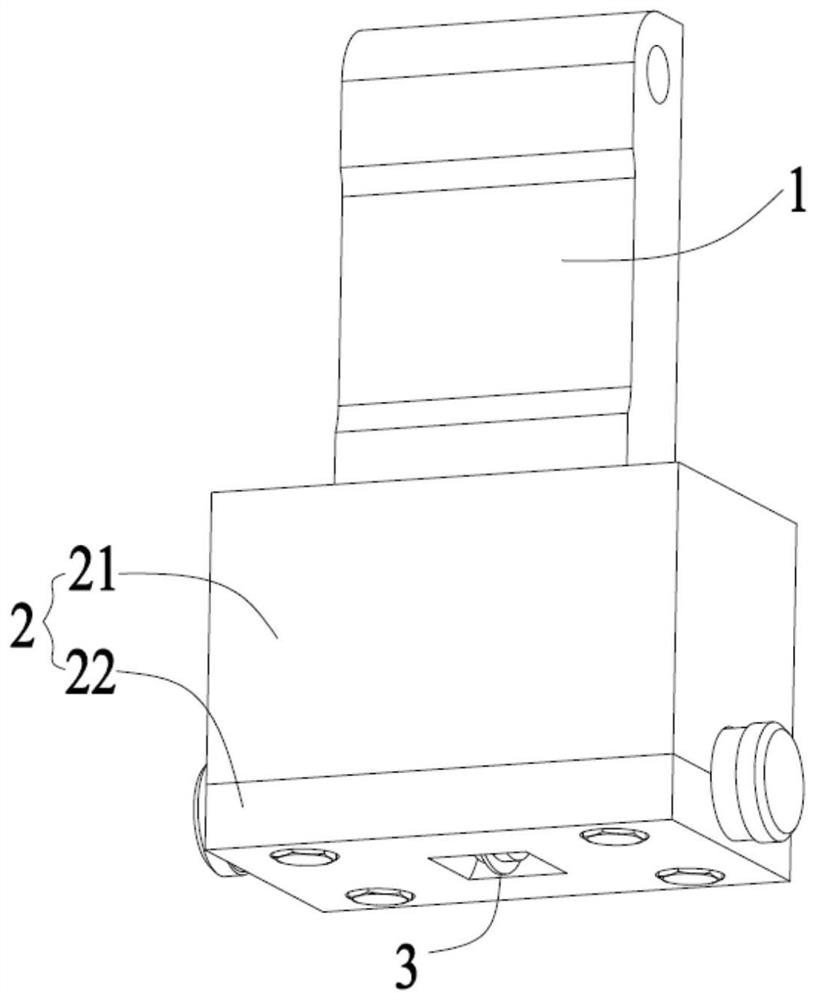

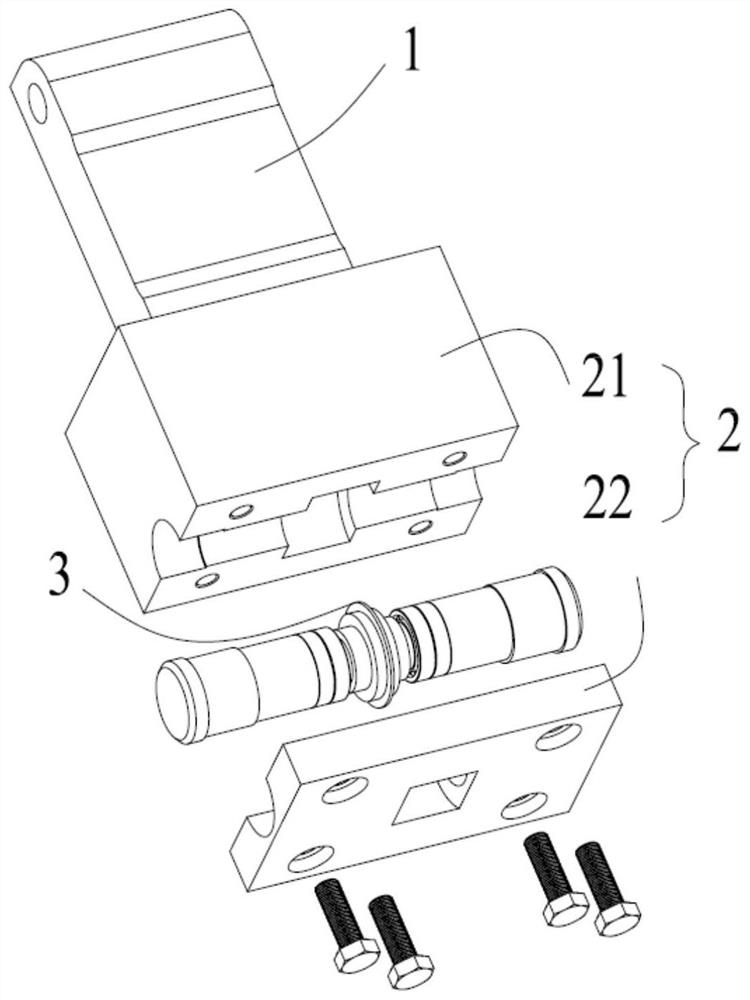

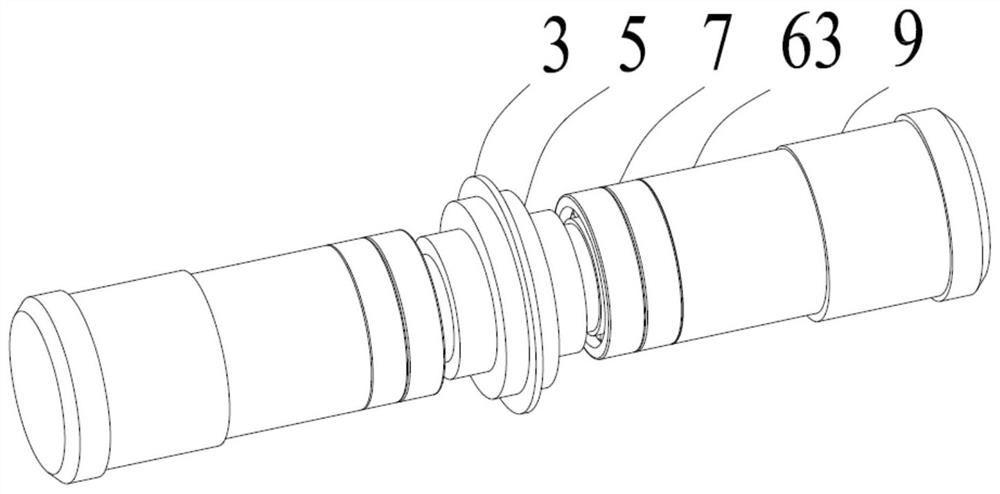

TBM hob cutter ring-rock opposite-grinding test device

A test device and cutter ring technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of lack of connection, complex structure and high cost of hob, so as to improve the utilization rate and value, and the accuracy of parameter control. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other. In the following description, many specific details are set forth in order to fully understand the present invention, and the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the implementation manners in the present invention, all other implementation manners obtained by persons of ordinary skill in the art without creative work, all belong to the scope of protection of the present invention.

[0046] Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly underst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com