Concrete structure post-installed instant sealing casing assembly and method of using the same

A technology of concrete structure and sealing casing, which is applied to building components, building insulation materials, etc., can solve the problems of uneven sealing effect, long duration, easy leakage, etc., and achieve waterproof sealing. Good effect, high installation efficiency and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

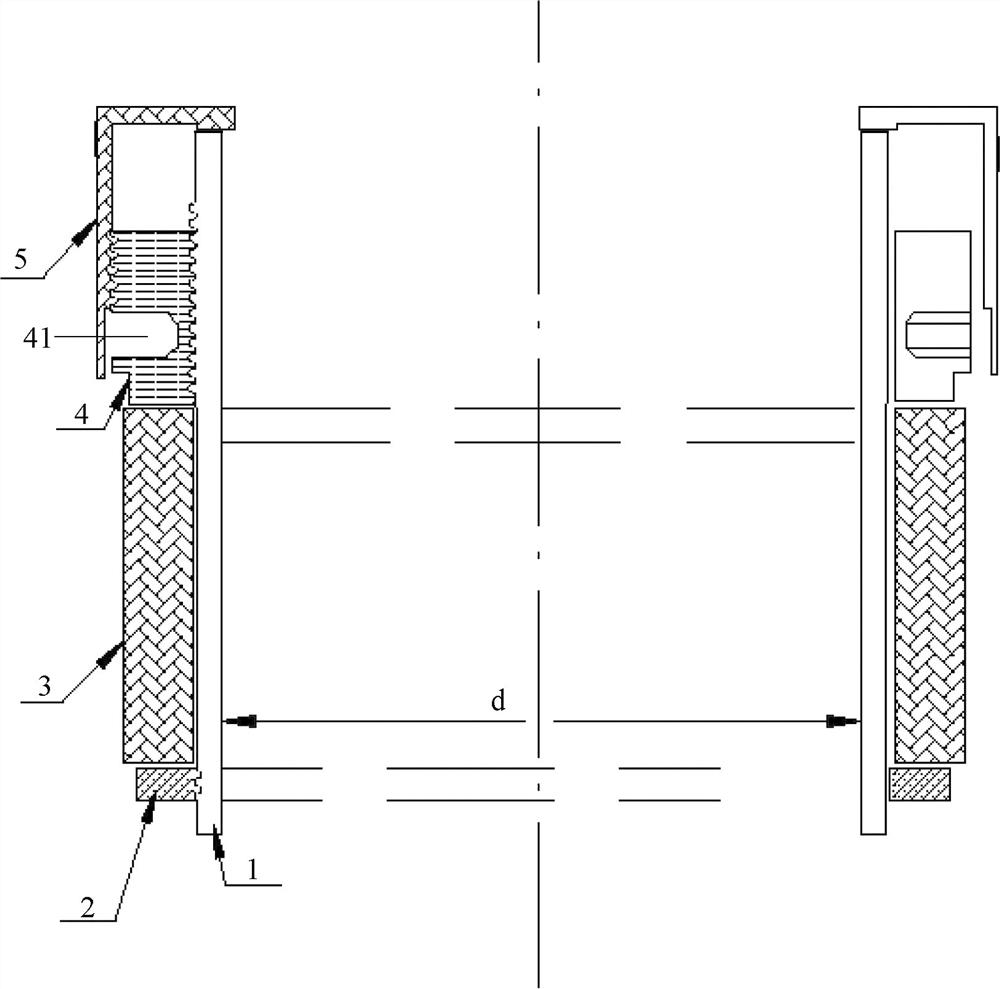

[0036] A concrete structure rear instant instant sealing sleeve component, including sleeve 1, front pressure ring 2. outer rubber sealing parts 3, rear pressure ring 4, and stitch 5, such as figure 1 The specific structure is:

[0037] There is an external thread on the outside of the sleeve 1;

[0038] The front pressure ring 2. outer rubber sealing parts 3 and rear pressure ring 4 are all circular and set up on the outside of the sleeve 1 from the front end of the sleeve 1.

[0039] The hole wall of the front pressure ring 2 has an internal thread that matches the outer thread 1 outer thread on the hole. The front pressure ring 2 spins the front end of the outer side of the sleeve 1 through the inner thread;

[0040] The outer rubber seal 3 is a ring shape, and the pore diameter of the inner pores of the outer rubber sealing parts 3 forms an over -profit coordination of the outer diameter of the pipe 1. Adjacent settings;

[0041] The rear pressure ring 4 is a two -stage stairo...

Embodiment 2

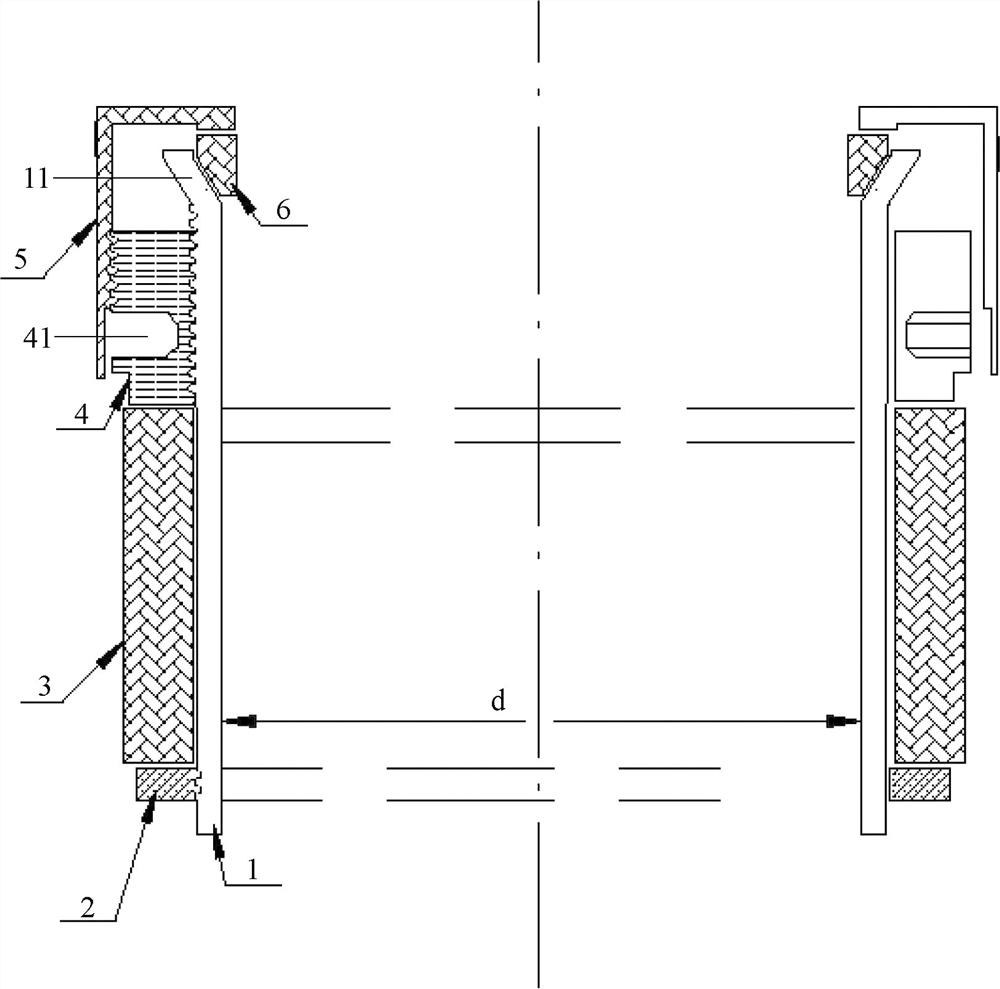

[0057] An instantaneous sealing sleeve component component of the concrete structure, including sleeve 1, front pressure ring 2. outer rubber sealing parts 3, rear pressure ring 4. Cover 5, inner rubber sealing parts 6, such as figure 2 The specific structure is:

[0058] There is an outer thread on the outside of the sleeve 1, and the back end of the sleeve 1 is equipped with a circular ring -shaped expansion ring 11.

[0059] The front pressure ring 2. outer rubber sealing parts 3 and rear pressure ring 4 are all circular and set up on the outside of the sleeve 1 from the front end of the sleeve 1.

[0060] The hole wall of the front pressure ring 2 has an internal thread that matches the outer thread 1 outer thread on the hole. The front pressure ring 2 spins the front end of the outer side of the sleeve 1 through the inner thread;

[0061] The outer rubber seal 3 is a ring shape, and the pore diameter of the inner pores of the outer rubber sealing parts 3 forms an over -profit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com