Concrete structure post-positioned instant sealing sleeve assembly and using method thereof

A concrete structure and sealing sleeve technology, applied to building components, building insulation materials, etc., can solve problems such as easy leakage, many processes, and long duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

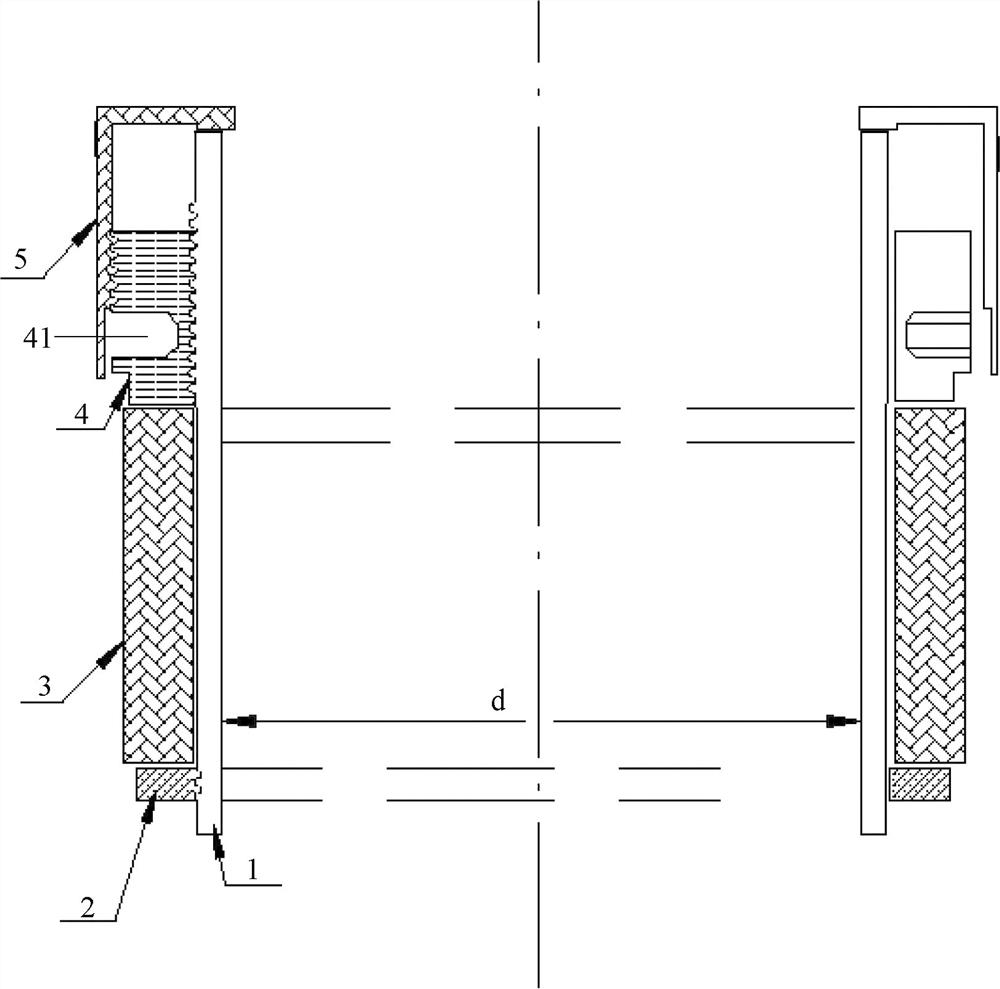

[0036] A concrete structure rear immediate sealing bushing assembly, including a bushing 1, a front pressure ring 2, an outer rubber seal 3, a rear pressure ring 4 and a gland 5, such as figure 1 As shown, the specific structure is:

[0037] External threads are provided on the outer surface of the casing 1;

[0038] The front pressure ring 2, the outer rubber seal 3 and the rear pressure ring 4 are all ring-shaped and are sleeved on the outer surface of the sleeve 1 sequentially from the front end of the sleeve 1,

[0039] The hole wall of the inner hole of the front pressure ring 2 is provided with an internal thread that matches the external thread of the casing 1, and the front pressure ring 2 is screwed on the front end of the outer surface of the casing 1 through the internal thread;

[0040] The outer rubber seal 3 is ring-shaped, and the diameter of the inner hole of the outer rubber seal 3 forms an interference fit with the outer diameter of the sleeve 1. The outer r...

Embodiment 2

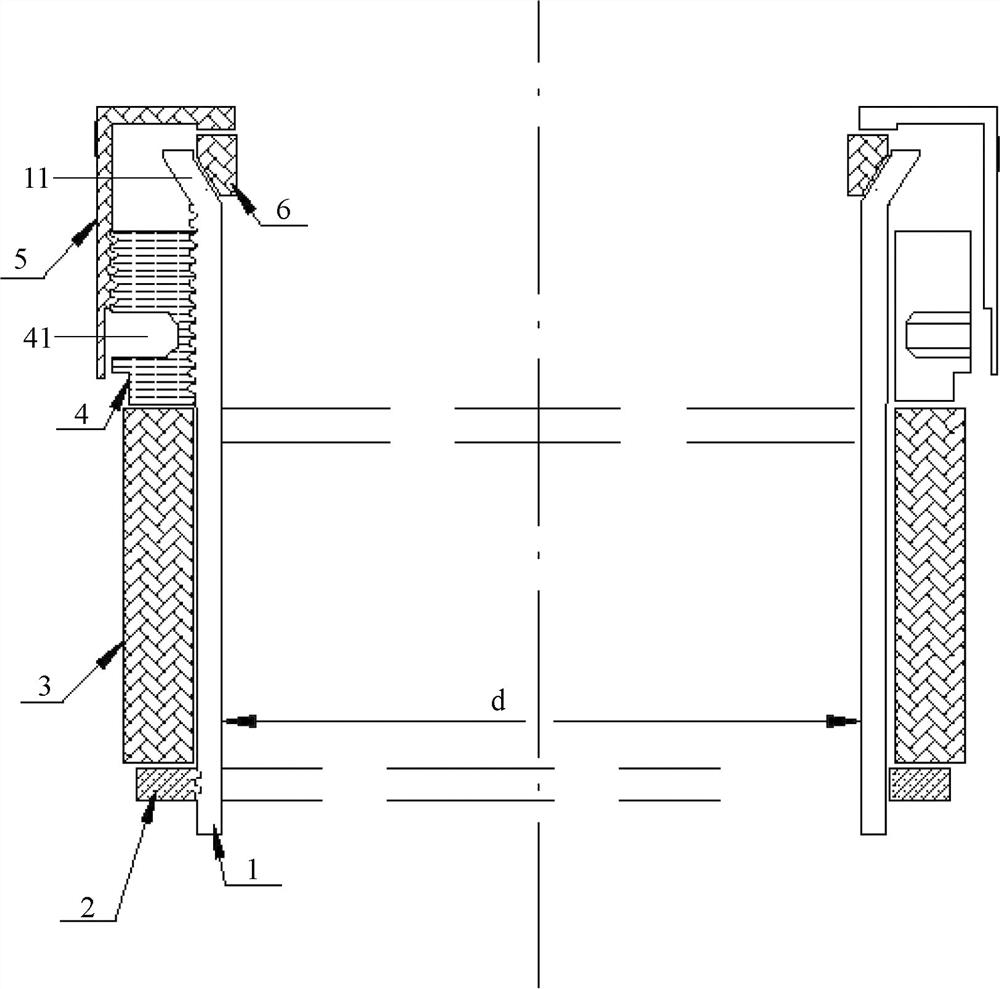

[0057] A concrete structure rear immediate sealing bushing assembly, including a bushing 1, a front pressure ring 2, an outer rubber seal 3, a rear pressure ring 4, a gland 5 and an inner rubber seal 6, such as figure 2 As shown, the specific structure is:

[0058] The outer surface of the casing 1 is provided with external threads, and the rear end of the casing 1 is provided with a conical expansion ring 11, and the expansion ring 11 is gradually opened backward from the rear end of the casing 1;

[0059] The front pressure ring 2, the outer rubber seal 3 and the rear pressure ring 4 are all ring-shaped and are sleeved on the outer surface of the sleeve 1 sequentially from the front end of the sleeve 1,

[0060] The hole wall of the inner hole of the front pressure ring 2 is provided with an internal thread that matches the external thread of the casing 1, and the front pressure ring 2 is screwed on the front end of the outer surface of the casing 1 through the internal thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com