Method for preventing bearing body babbitt metal from shelling after pouring

A bearing body and body bar technology, which is applied in metal material coating process, coating, hot dip plating process, etc., can solve the problems of tin layer influence, shell body and babbitt bonding force shelling, etc., to avoid demolition. shell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

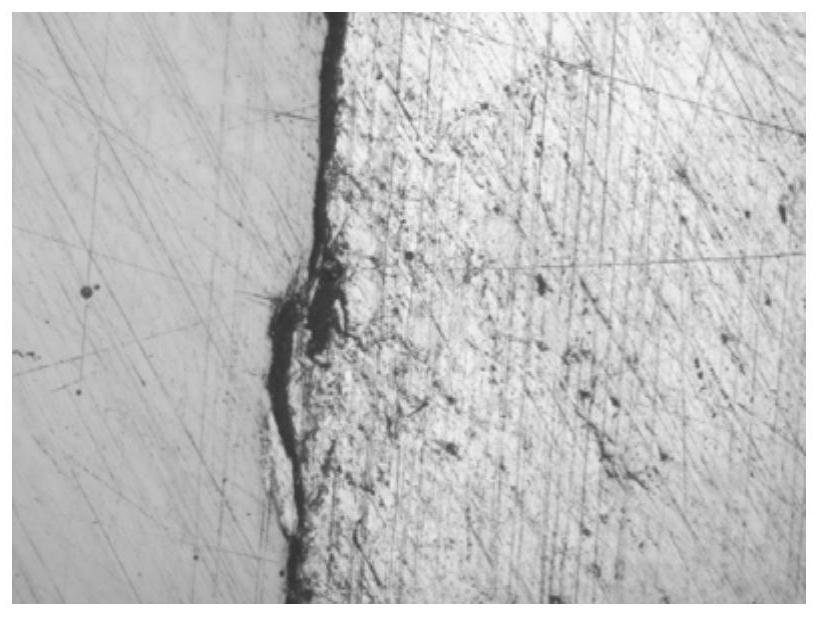

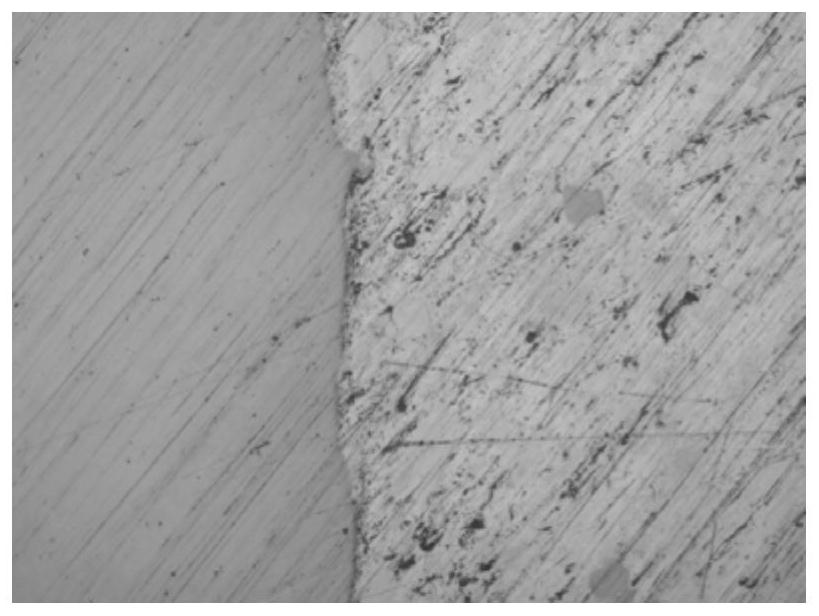

Image

Examples

specific Embodiment approach 1

[0011] Specific implementation mode 1: In this implementation mode, a method for avoiding shelling of the bearing body after casting Babbitt alloy is completed according to the following steps:

[0012] Immerse the pouring surface of the bearing shell of the pretreated bearing body into the tin liquid for the first tinning, and immediately sprinkle anhydrous ammonium chloride powder evenly on the pouring surface of the bearing shell after taking it out for 10s~15s, and then immerse it in the tin liquid for the second hanging. Tin, 10s~15s after taking it out again, immediately sprinkle anhydrous ammonium chloride powder evenly on the pouring surface of the bearing bush, and finally pour babbitt alloy liquid on the pouring surface of the bearing bush to complete the pouring of the bearing body babbitt alloy, the tin used for the first tinning The mass ratio of tin liquid and sprinkled anhydrous ammonium chloride powder is 1: (0.07-0.1), and the mass ratio of tin liquid used for ...

specific Embodiment approach 2

[0016] Specific Embodiment 2: The difference between this embodiment and Specific Embodiment 1 is that the steps of pretreatment of the bearing pad of the bearing body are as follows: first, the bearing pad is roughly machined, and then the stress is removed by heat treatment, and then the pouring surface of the bearing pad is treated with hydrochloric acid solution. Carry out rust removal, use ethanol solution to clean after rust removal, and finally coat zinc chloride solution evenly on the pouring surface to obtain the pretreated bearing shell.

[0017] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The differences between this embodiment and Embodiment 1 or 2 are: the outer diameter of the bearing body is Φ362mm, the inner diameter is Φ262mm, and the thickness is 166mm; the bearing body is made of 25# steel.

[0019] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com