Aluminum alloy sheet

An aluminum alloy plate and quality technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of increased usage and material cost, and achieve the effect of improving strength and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

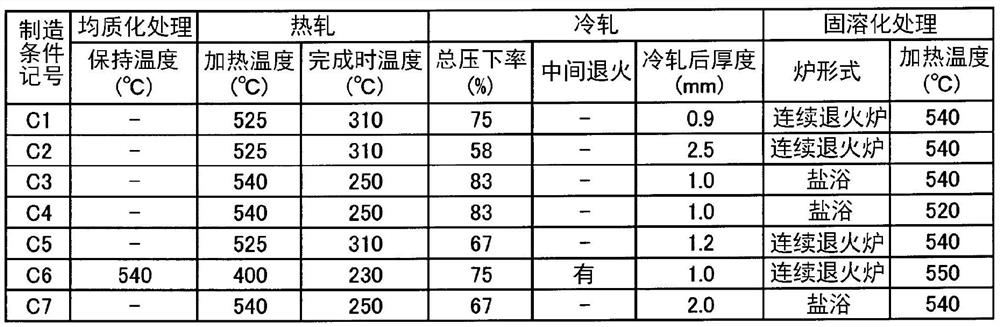

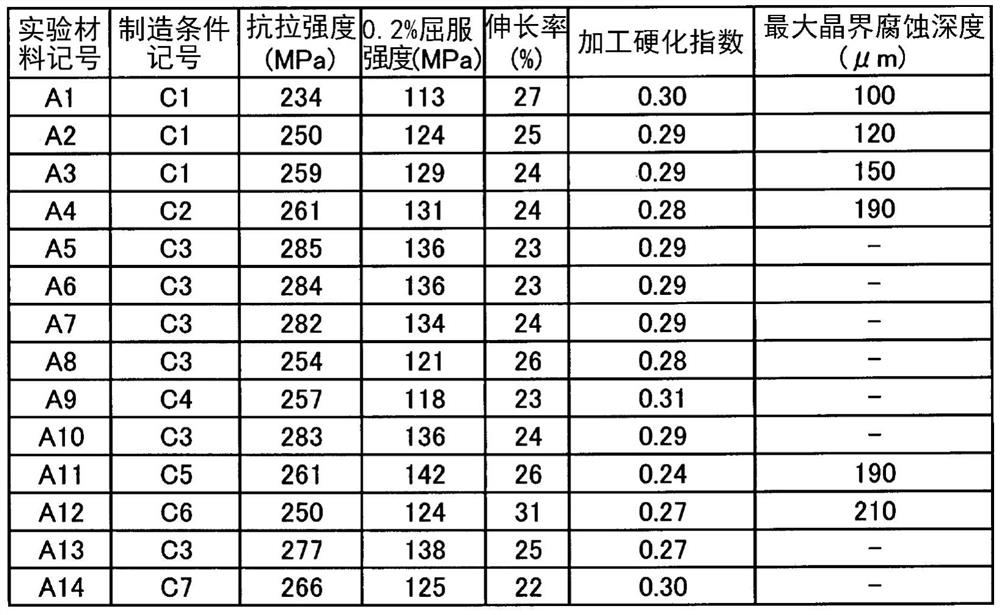

Method used

Image

Examples

Embodiment Construction

[0020] (Aluminum alloy plate)

[0021] The aluminum alloy plate contains Si, Mn, Mg, and Fe, Mg, and Fe as essential components. In addition, the aluminum alloy plate contains one or two or more elements of Cu, Cr, Zn, and Ti in addition to these essential components. The aluminum alloy plate may further contain Ni (nickel) as an optional component. Hereinafter, the chemical components of the aluminum alloy plate and the reason for limitation thereof will be described in detail.

[0022] ・Si: 2.3% by mass to 3.8% by mass

[0023] The aluminum alloy plate contains 2.3% by mass or more and 3.8% by mass or less of Si as an essential component. Part of Si exists in the aluminum alloy plate as solid solution Si dissolved in the Al matrix. In addition, Si that is not solid-dissolved in the Al matrix is represented by simple Si, Mg 2 Si, Al-(Fe,Mn)-Si-based intermetallic compounds, Al-Mn-Si-based intermetallic compounds, Al-Fe-Si-based intermetallic compounds, and the like exi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com