Mold half and method for producing injection molded part having at least one insert

A technology of embedded parts and injection molded parts, applied in the direction of coating, etc., can solve the problems of cumbersome cost, cumbersome manipulation and positioning, and high cost, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

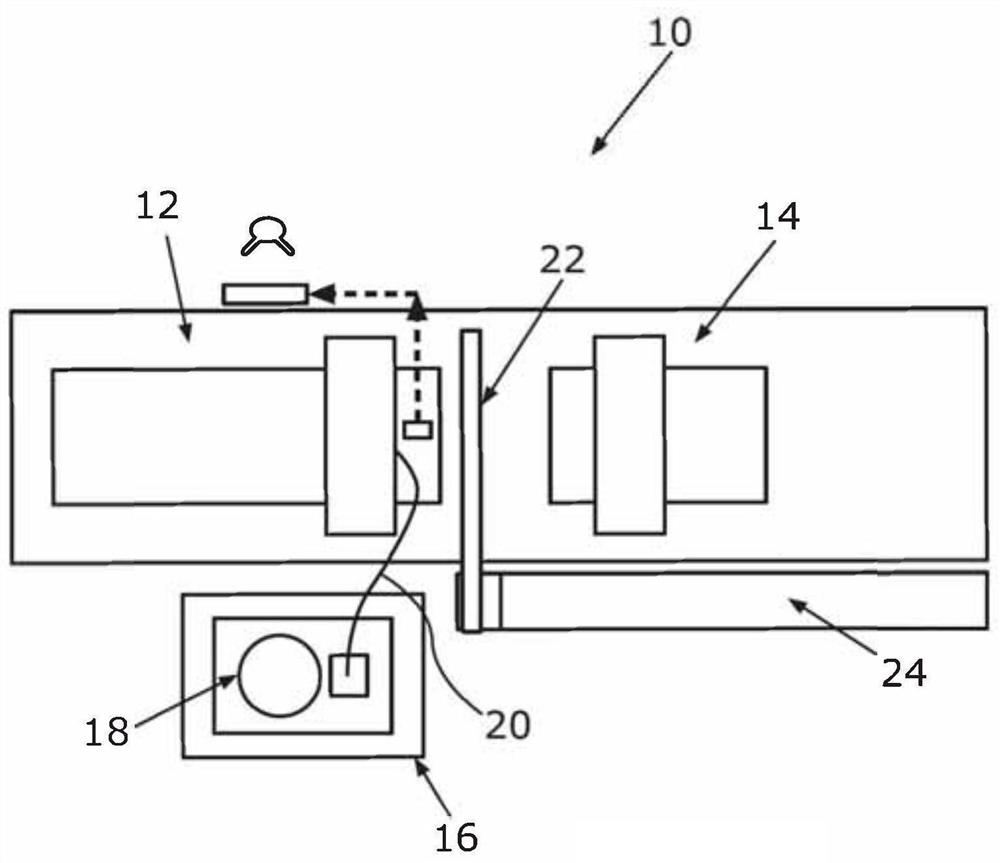

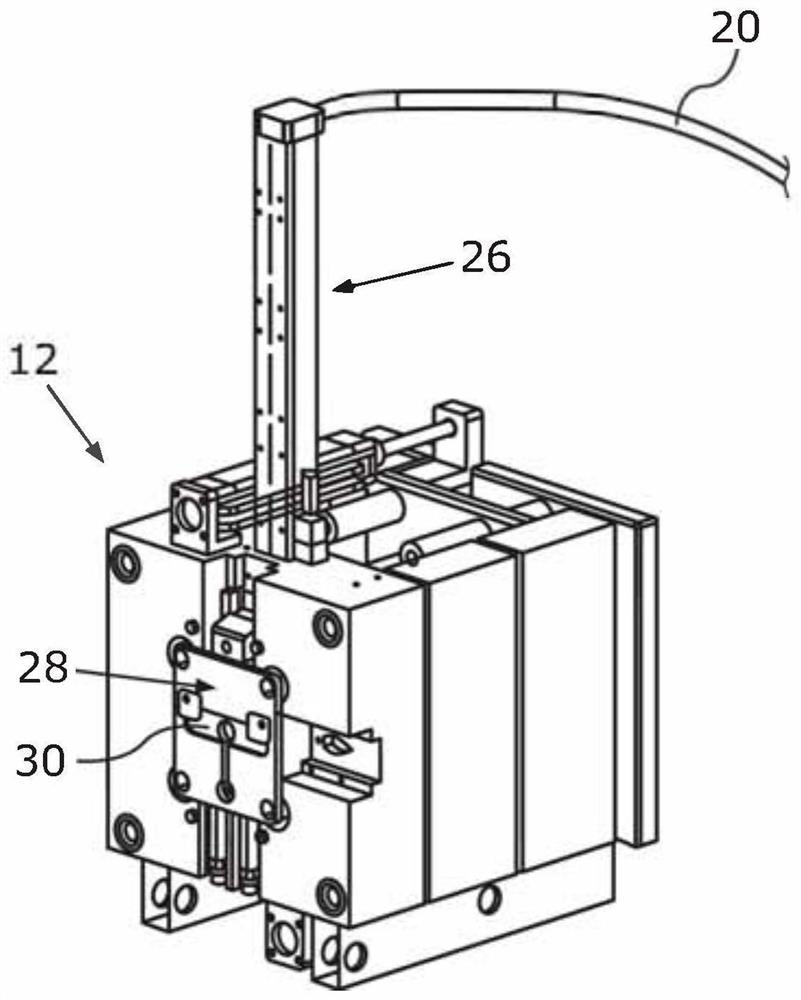

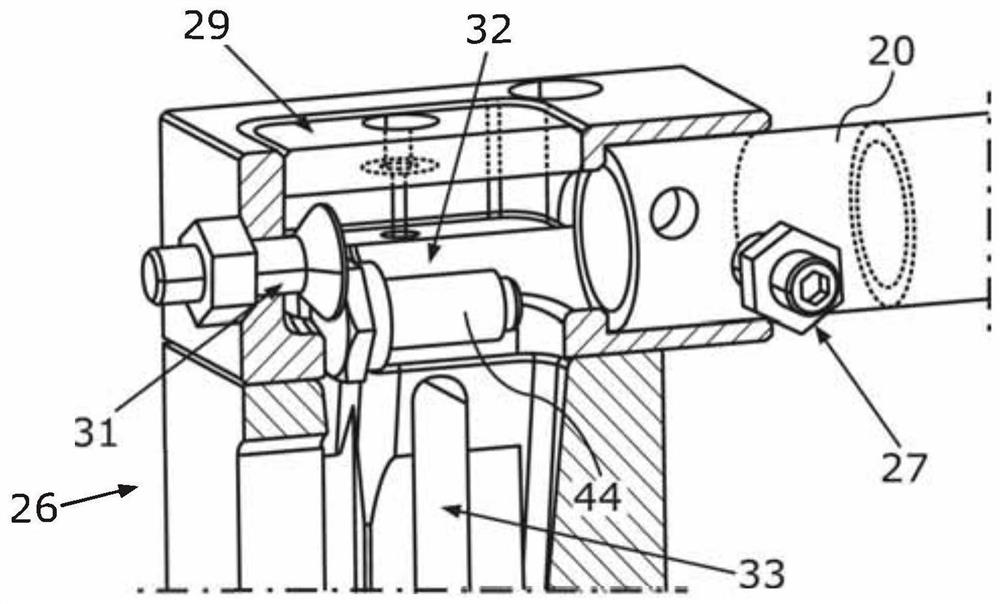

[0038] exist figure 1 The injection molding machine 10 is shown in a schematic top view of . The injection molding machine 10 comprises two mold halves 12 , 14 with which injection molded parts can be produced with injection-molded inserts. The mold half 12 on the left according to the illustration includes an integrated feed mechanism, by means of which inserts can be fed into the area of the cavity of the two mold halves 12 , 14 . The injection molding machine 10 may also include a supply enclosure 16 which may have a shake tank 18 for stocking and separating keyed inserts. The supply periphery 16 can also have a hose 20 by means of which the separate inserts can be supplied to the mold halves 12 pneumatically, for example. The entire supply periphery 16 can be designed to be removable, ie it can be supplied to different injection molding machines 10 as required. The injection molding machine 10 can also have a linear manipulator 22 or a robot, by means of which the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com