Abrasive belt knife sharpening method and knife sharpening device thereof

A knife sharpening device and abrasive belt technology, which is applied to abrasive belt grinders, grinding machines, grinding/polishing equipment, etc., can solve the problems of intricate and cumbersome connection of pull ropes, affecting the cutting effect of cutting machines, and the number of overall parts, etc., to achieve Smooth inner wall with low friction, stable sharpening effect and good sharpening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

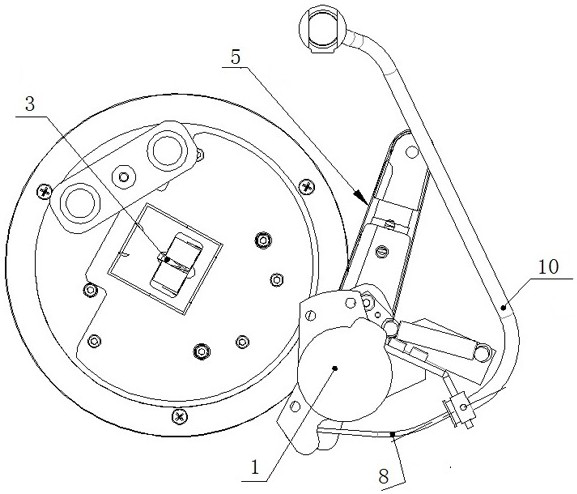

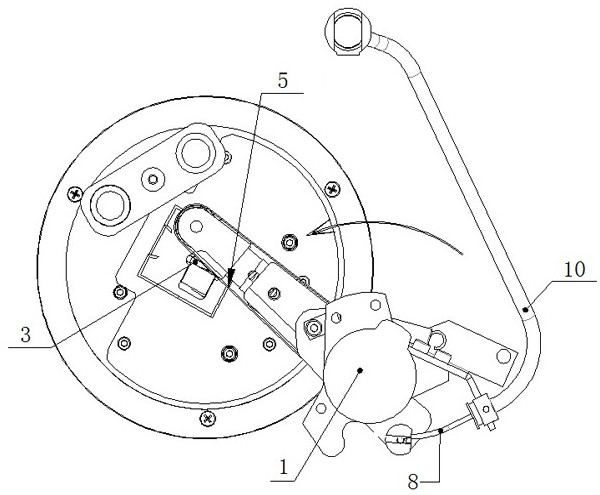

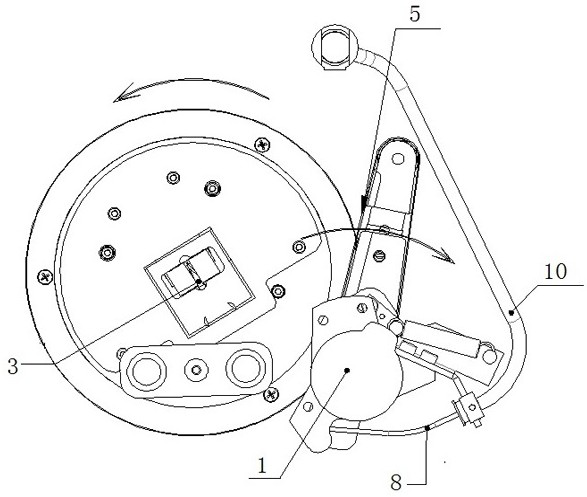

[0019] see Figure 1 to Figure 6 , the abrasive belt sharpening device of this embodiment includes a sharpening motor 1, a motor base 2, a coupling 3, a sharpening mechanism 4, an abrasive belt 5, a drawstring cylinder 6, a cylinder joint 7, a drawstring 8 and a rotatable connecting column 12. The knife sharpening motor 1 is installed on the motor base 2, and the motor base 2 is installed on the main support of the knife sharpening mechanism 4. The output shaft of the knife sharpening motor 1 is connected with the rotating shaft of the knife sharpening mechanism 4 through the coupling 3.

[0020] The cylinder joint 7 is installed on the piston rod of the stay cord cylinder 6 of the present embodiment, and the cylinder joint 7 is connected with one end of the stay cord 8, and the stay cord 8 passes through the stay cord fixing sleeve 9, the stay cord casing 10, and the stay cord successively. Cover two 11, the other end of the stay cord 8 is directly fixed with the rotatable co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com