A processing method of a shell and a straightening die device thereof

A processing method and shell technology, which is applied in the field of aerospace manufacturing, can solve the problems of multiple clamping and positioning reference instability, increased processing time, and easy deformation of profiles, so as to reduce preparation time, reduce total processing time, and simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

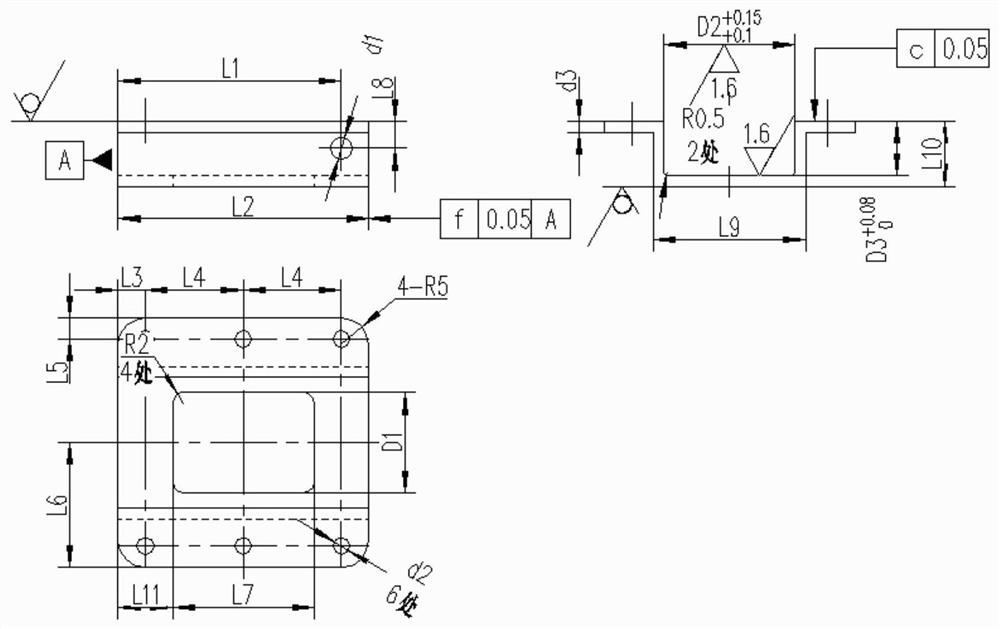

[0033] Example 1 is as Figures 1 to 4 As shown in the figure, a processing method of a shell, the specific steps are as follows:

[0034] 1) Material preparation: Prepare LY12-CZ aluminum profile according to GBn222-1984, and the profile size L9 has been formed; preparation time: 30 minutes, processing time: 30 seconds.

[0035] 2) sawing machine cutting: the figure 1 Milling from L2 to (L2+1)mm, this process can process multiple profiles at a time; preparation time: 30 minutes, processing time: 10 seconds.

[0036] 3) Counting milling: Clamping L9, milling L2 and 4-R5 size; preparation time: 120 minutes, single piece processing time: 120 seconds.

[0037] 4) Fitter: remove the burr after milling; preparation time: 30 minutes, processing time: 60 seconds.

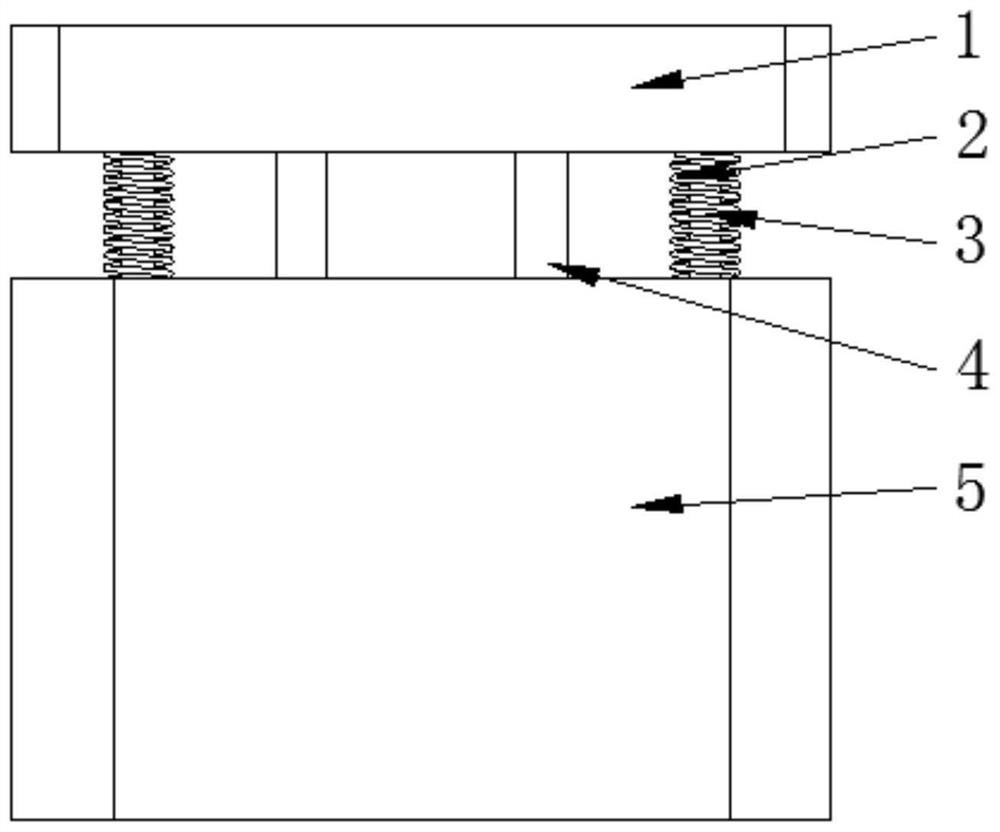

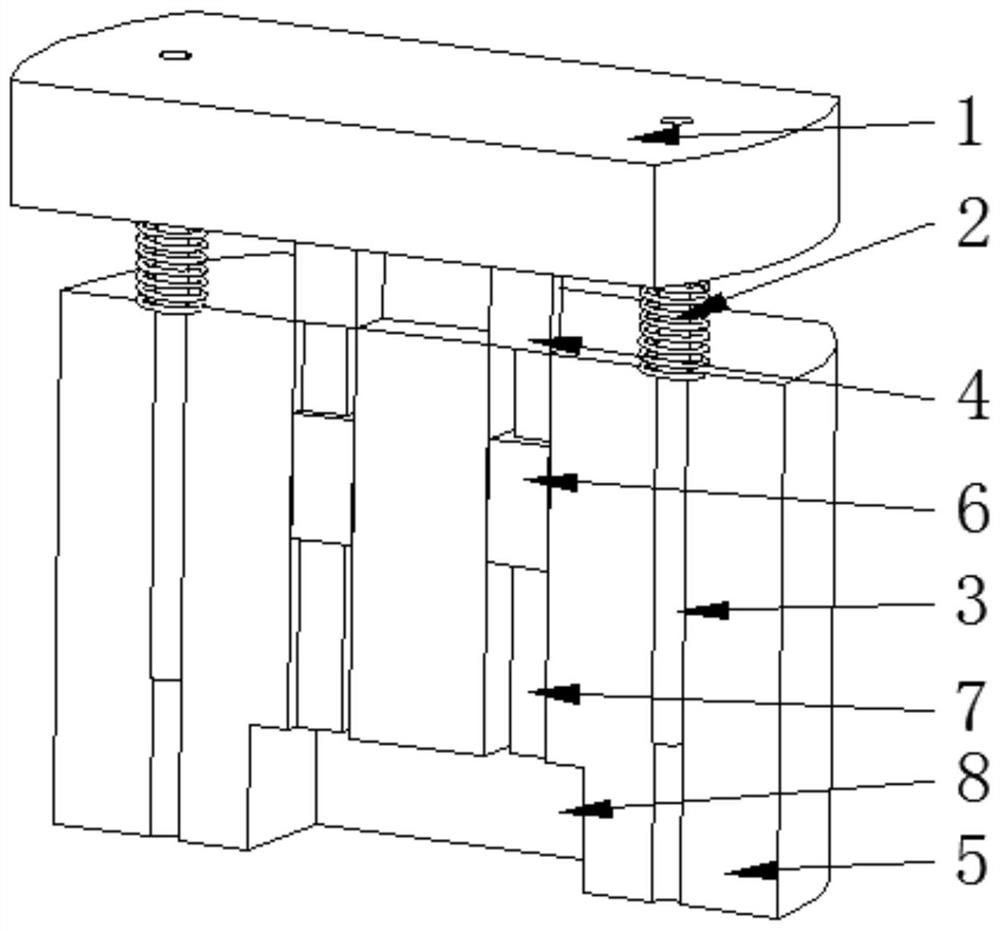

[0038] 5) Correction: Align the semi-finished product 6 with the shape of the product to the via hole 7, insert part of the semi-finished product 6 into the via hole 7, set the spring 2 on the positioning pin 3, align t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com